Insulated Concrete Forms (ICFs) offer superior thermal insulation compared to traditional concrete blocks, reducing energy costs and improving building comfort. ICFs also provide enhanced structural strength and soundproofing due to their composite construction of foam insulation and concrete core. Concrete blocks remain a cost-effective and widely used option but generally require additional insulation to meet modern energy efficiency standards.

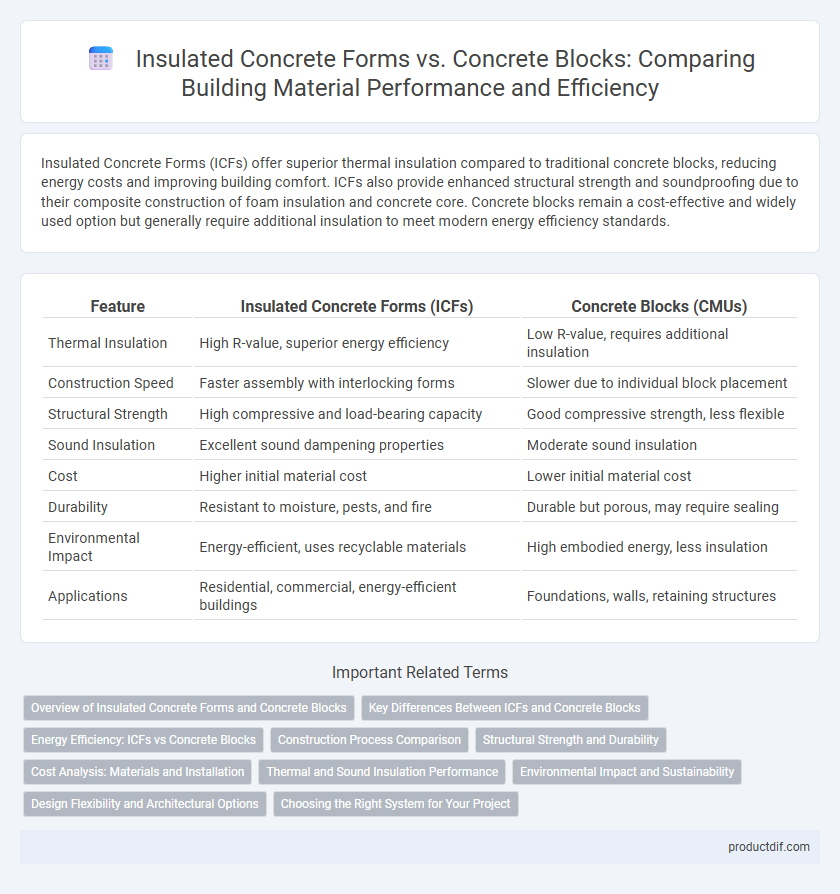

Table of Comparison

| Feature | Insulated Concrete Forms (ICFs) | Concrete Blocks (CMUs) |

|---|---|---|

| Thermal Insulation | High R-value, superior energy efficiency | Low R-value, requires additional insulation |

| Construction Speed | Faster assembly with interlocking forms | Slower due to individual block placement |

| Structural Strength | High compressive and load-bearing capacity | Good compressive strength, less flexible |

| Sound Insulation | Excellent sound dampening properties | Moderate sound insulation |

| Cost | Higher initial material cost | Lower initial material cost |

| Durability | Resistant to moisture, pests, and fire | Durable but porous, may require sealing |

| Environmental Impact | Energy-efficient, uses recyclable materials | High embodied energy, less insulation |

| Applications | Residential, commercial, energy-efficient buildings | Foundations, walls, retaining structures |

Overview of Insulated Concrete Forms and Concrete Blocks

Insulated Concrete Forms (ICFs) are hollow foam blocks or panels that are stacked to create a mold for poured concrete, providing enhanced thermal insulation and energy efficiency compared to traditional Concrete Blocks, which are solid or hollow masonry units commonly used for structural walls. ICFs combine the strength and durability of reinforced concrete with the insulation properties of expanded polystyrene, resulting in superior airtightness and reduced thermal bridging. Concrete Blocks offer cost-effectiveness and ease of installation but lack the integrated insulation features found in ICF systems, impacting their overall energy performance.

Key Differences Between ICFs and Concrete Blocks

Insulated Concrete Forms (ICFs) combine rigid insulation with concrete, providing superior thermal performance and energy efficiency compared to traditional Concrete Blocks, which lack integrated insulation. ICFs create a continuous insulated wall that reduces thermal bridging, enhances soundproofing, and improves structural strength, whereas Concrete Blocks require additional insulation layers to achieve similar benefits. The installation process for ICFs is typically faster and results in higher airtightness, while Concrete Blocks offer more flexibility in design but often demand extra labor for insulation and finishing.

Energy Efficiency: ICFs vs Concrete Blocks

Insulated Concrete Forms (ICFs) provide superior energy efficiency compared to traditional concrete blocks due to their continuous insulation and airtight construction, which minimizes heat transfer and reduces thermal bridging. The higher R-values of ICFs contribute to significant energy savings in heating and cooling, often outperforming concrete blocks by up to 50%. This improved insulation performance results in lower utility bills and enhanced indoor comfort over the building's lifespan.

Construction Process Comparison

Insulated Concrete Forms (ICFs) streamline the construction process by combining insulation and structural support in one step, reducing labor time and minimizing the need for additional insulation installation. Concrete blocks require multiple stages, including laying, mortar application, and separate insulation installation, which increases construction time and labor costs. ICFs also provide enhanced energy efficiency and superior soundproofing compared to traditional concrete blocks, improving overall building performance.

Structural Strength and Durability

Insulated Concrete Forms (ICFs) provide superior structural strength compared to traditional concrete blocks due to their continuous reinforced concrete core, enhancing load-bearing capacity and resistance to seismic and wind forces. The integrated insulation in ICFs also prevents thermal bridging, contributing to long-term durability by reducing moisture infiltration and thermal degradation. Concrete blocks, while robust, often require additional insulation and are more susceptible to cracking and water damage over time.

Cost Analysis: Materials and Installation

Insulated Concrete Forms (ICFs) typically have higher upfront material costs compared to standard concrete blocks, but their superior thermal insulation reduces long-term energy expenses. Installation of ICFs may require specialized labor, increasing initial construction costs, while concrete blocks are more widely used and often involve less skilled labor, lowering installation expenses. Considering both materials and installation, ICFs provide a cost-effective solution over time due to enhanced energy efficiency and decreased maintenance needs.

Thermal and Sound Insulation Performance

Insulated Concrete Forms (ICFs) provide superior thermal insulation with R-values typically ranging from R-20 to R-30, significantly reducing energy costs compared to traditional concrete blocks, which generally have R-values around R-1 to R-2. ICFs feature continuous insulation that minimizes thermal bridging, enhancing overall building envelope performance. Sound insulation in ICFs also excels, with STC (Sound Transmission Class) ratings often exceeding 50 due to the combination of concrete and foam insulation, whereas concrete blocks usually have lower STC ratings around 40, leading to increased noise transmission.

Environmental Impact and Sustainability

Insulated Concrete Forms (ICFs) significantly reduce thermal bridging and enhance energy efficiency, leading to lower greenhouse gas emissions over a building's lifecycle compared to traditional concrete blocks. ICFs use expanded polystyrene foam, which is recyclable and improves insulation, whereas concrete blocks have higher embodied energy due to cement production and offer less thermal performance. Sustainable building practices increasingly favor ICFs for their ability to reduce operational energy consumption and minimize carbon footprint, supporting long-term environmental goals.

Design Flexibility and Architectural Options

Insulated Concrete Forms (ICFs) offer superior design flexibility compared to traditional concrete blocks, allowing for curved walls, varied shapes, and integrated insulation within the structure. The modular nature of ICFs supports complex architectural designs and enhanced energy efficiency, making them ideal for modern, sustainable buildings. Concrete blocks, while durable, are limited in shape and require additional insulation, restricting creative architectural possibilities.

Choosing the Right System for Your Project

Insulated Concrete Forms (ICFs) deliver superior energy efficiency and enhanced structural strength compared to traditional concrete blocks by combining rigid foam insulation with reinforced concrete. Concrete blocks offer cost-effective construction with versatility and ease of use but lack the thermal insulation properties of ICFs, impacting long-term energy savings. Selecting the right system depends on project goals, budget constraints, and performance priorities such as insulation value (R-value), durability, and environmental considerations.

Insulated Concrete Forms vs Concrete Blocks Infographic

productdif.com

productdif.com