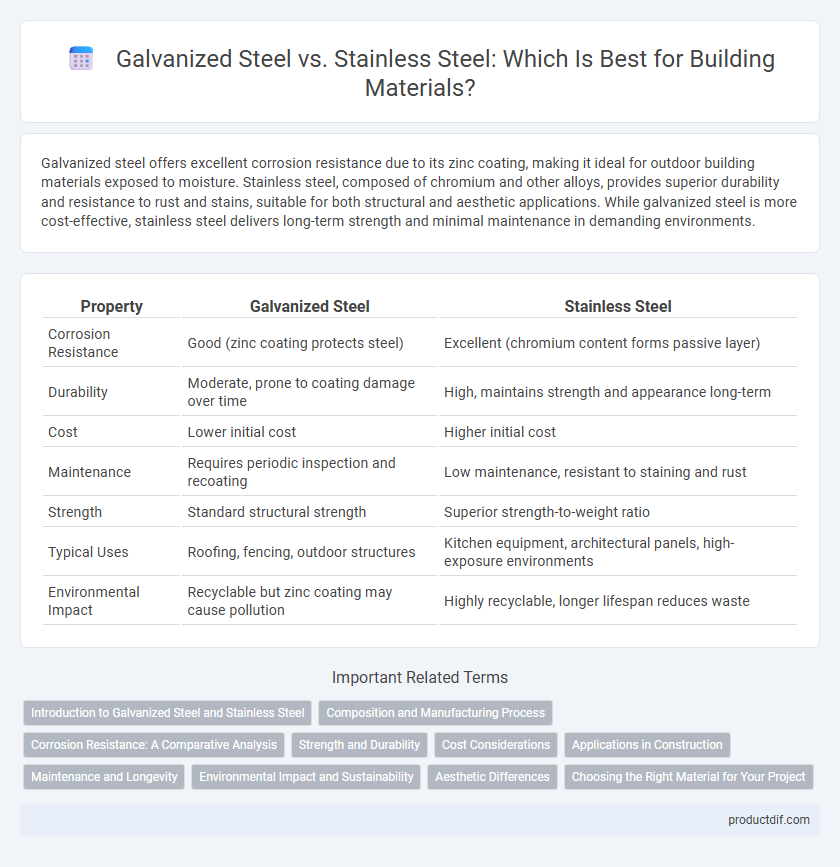

Galvanized steel offers excellent corrosion resistance due to its zinc coating, making it ideal for outdoor building materials exposed to moisture. Stainless steel, composed of chromium and other alloys, provides superior durability and resistance to rust and stains, suitable for both structural and aesthetic applications. While galvanized steel is more cost-effective, stainless steel delivers long-term strength and minimal maintenance in demanding environments.

Table of Comparison

| Property | Galvanized Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good (zinc coating protects steel) | Excellent (chromium content forms passive layer) |

| Durability | Moderate, prone to coating damage over time | High, maintains strength and appearance long-term |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Requires periodic inspection and recoating | Low maintenance, resistant to staining and rust |

| Strength | Standard structural strength | Superior strength-to-weight ratio |

| Typical Uses | Roofing, fencing, outdoor structures | Kitchen equipment, architectural panels, high-exposure environments |

| Environmental Impact | Recyclable but zinc coating may cause pollution | Highly recyclable, longer lifespan reduces waste |

Introduction to Galvanized Steel and Stainless Steel

Galvanized steel features a protective zinc coating that enhances corrosion resistance, making it ideal for construction and outdoor applications. Stainless steel contains chromium, providing superior durability, resistance to rust, and a sleek finish favored in architectural and structural projects. Both materials offer distinct advantages in strength and longevity, tailored to specific building requirements.

Composition and Manufacturing Process

Galvanized steel consists of carbon steel coated with a layer of zinc through a hot-dip or electro-galvanizing process to enhance corrosion resistance, while stainless steel is an alloy primarily made of iron, chromium (usually 10.5% or more), and nickel, providing inherent rust and stain resistance. The manufacturing process for galvanized steel involves coating the base steel with molten zinc, creating a sacrificial barrier, whereas stainless steel is produced through alloying and specialized heat treatments to achieve its durability and corrosion resistance. Differences in composition and processing directly influence their performance, cost, and suitability for various building applications.

Corrosion Resistance: A Comparative Analysis

Galvanized steel features a zinc coating that provides effective corrosion resistance by forming a protective barrier against moisture and oxygen, making it suitable for outdoor and industrial applications. Stainless steel contains chromium, which forms a passive oxide layer that prevents rust and ensures superior durability in highly corrosive environments, including marine and chemical settings. The choice between galvanized and stainless steel depends on specific environmental exposure and required longevity, with stainless steel offering more robust and long-term corrosion protection.

Strength and Durability

Galvanized steel offers enhanced corrosion resistance through a zinc coating, making it highly durable for outdoor and industrial applications. Stainless steel, composed mainly of iron, chromium, and nickel, provides superior strength and long-term durability due to its inherent resistance to rust, oxidation, and extreme temperatures. Both materials excel in structural integrity, but stainless steel typically outperforms galvanized steel in strength retention and lifespan under harsh conditions.

Cost Considerations

Galvanized steel typically costs less than stainless steel due to the lower price of zinc coating compared to the alloying elements in stainless steel. Maintenance expenses are generally lower for stainless steel as it offers superior corrosion resistance, reducing repainting or rust treatment costs. The initial investment in stainless steel may be higher, but long-term savings often justify the premium in projects requiring durability and minimal upkeep.

Applications in Construction

Galvanized steel is widely used in construction for structural framing, roofing, and exterior siding due to its corrosion resistance and cost-effectiveness. Stainless steel is preferred for architectural features, fasteners, and high-stress load-bearing components where durability and aesthetic appeal are critical. Both materials enhance building longevity, but stainless steel offers superior resistance to harsh environments, making it ideal for marine and chemical-exposed structures.

Maintenance and Longevity

Galvanized steel offers excellent corrosion resistance due to its zinc coating, making it low maintenance and ideal for outdoor applications where exposure to moisture is common. Stainless steel, composed primarily of iron, chromium, and nickel, provides superior durability and corrosion resistance in harsh environments, requiring minimal upkeep and maintaining structural integrity over decades. Choosing between galvanized and stainless steel depends on environmental conditions and budget, with stainless steel generally delivering longer longevity and lower maintenance costs in corrosive or high-wear settings.

Environmental Impact and Sustainability

Galvanized steel has a significant environmental footprint due to the zinc coating process, which involves energy-intensive mining and potential zinc runoff causing soil contamination. Stainless steel, composed mainly of iron, chromium, and nickel, offers enhanced durability and recyclability, reducing the need for frequent replacement and minimizing landfill waste. Both materials contribute to sustainability when recycled, but stainless steel's longer lifespan and higher corrosion resistance make it a more eco-friendly choice for long-term construction projects.

Aesthetic Differences

Galvanized steel features a matte gray finish with a textured, spangled pattern resulting from its zinc coating, which offers a rugged, industrial look ideal for outdoor or utilitarian applications. Stainless steel presents a smooth, reflective surface with a naturally bright, silver sheen that resists tarnishing and enhances modern architectural aesthetics. The choice between galvanized and stainless steel impacts the visual appeal, with galvanized steel providing a more rustic appearance and stainless steel delivering a sleek, polished finish.

Choosing the Right Material for Your Project

Galvanized steel offers excellent corrosion resistance through a protective zinc coating, making it ideal for outdoor or moisture-exposed building projects where budget constraints exist. Stainless steel provides superior durability and resistance to rust and stains due to its chromium content, recommended for high-strength and long-lasting structural applications requiring a polished finish. Evaluating project-specific factors like environmental exposure, mechanical stress, and cost will help determine whether galvanized or stainless steel is the optimal building material.

Galvanized Steel vs Stainless Steel Infographic

productdif.com

productdif.com