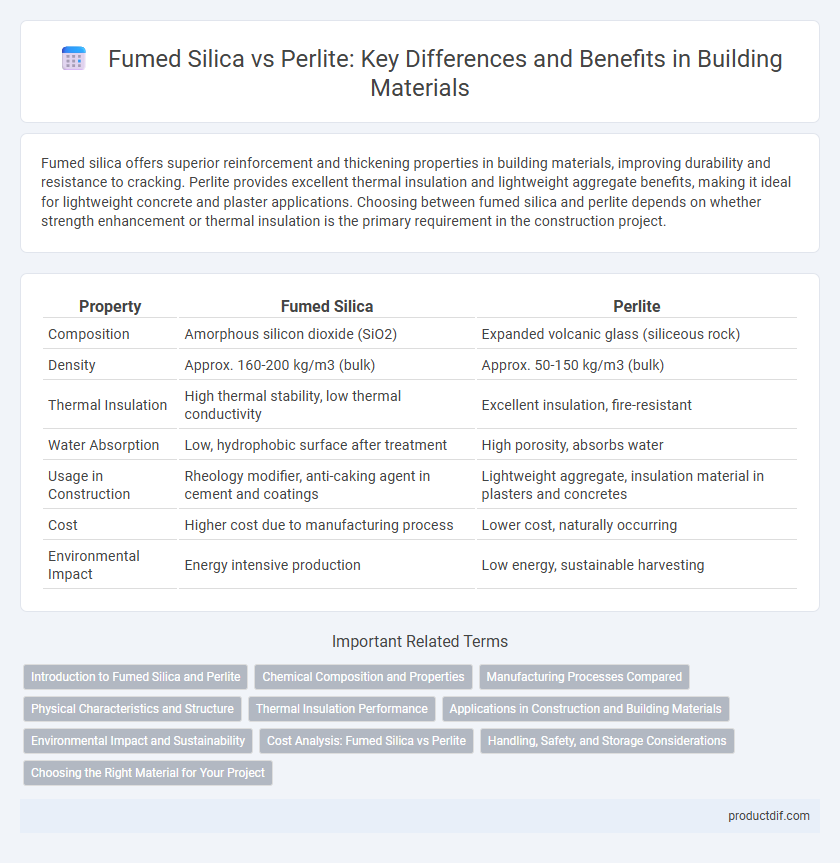

Fumed silica offers superior reinforcement and thickening properties in building materials, improving durability and resistance to cracking. Perlite provides excellent thermal insulation and lightweight aggregate benefits, making it ideal for lightweight concrete and plaster applications. Choosing between fumed silica and perlite depends on whether strength enhancement or thermal insulation is the primary requirement in the construction project.

Table of Comparison

| Property | Fumed Silica | Perlite |

|---|---|---|

| Composition | Amorphous silicon dioxide (SiO2) | Expanded volcanic glass (siliceous rock) |

| Density | Approx. 160-200 kg/m3 (bulk) | Approx. 50-150 kg/m3 (bulk) |

| Thermal Insulation | High thermal stability, low thermal conductivity | Excellent insulation, fire-resistant |

| Water Absorption | Low, hydrophobic surface after treatment | High porosity, absorbs water |

| Usage in Construction | Rheology modifier, anti-caking agent in cement and coatings | Lightweight aggregate, insulation material in plasters and concretes |

| Cost | Higher cost due to manufacturing process | Lower cost, naturally occurring |

| Environmental Impact | Energy intensive production | Low energy, sustainable harvesting |

Introduction to Fumed Silica and Perlite

Fumed silica is a highly pure, amorphous form of silicon dioxide produced through flame hydrolysis, widely used as a thickening and anti-caking agent in construction materials due to its fine particle size and high surface area. Perlite, a naturally occurring volcanic glass, expands when heated and serves as a lightweight aggregate and insulating additive in concrete and plaster. Both materials enhance durability and thermal performance in building applications, with fumed silica contributing to improved rheology and perlite offering superior insulation and fire resistance.

Chemical Composition and Properties

Fumed silica consists of amorphous silicon dioxide with a high surface area and purity, providing excellent thickening and anti-caking properties in building materials. Perlite is a volcanic glass primarily composed of hydrated silica, aluminum oxide, and alkali oxides, valued for its lightweight, thermal insulation, and fire-resistant characteristics. The chemically inert nature of fumed silica contrasts with perlite's porous structure, influencing their specific applications in concrete, plaster, and insulation products.

Manufacturing Processes Compared

Fumed silica is produced through a high-temperature vapor phase hydrolysis of silicon tetrachloride, resulting in ultra-fine, amorphous silica particles with a large surface area. Perlite manufacturing involves mining natural volcanic glass and rapidly heating it to about 850-900degC, causing it to expand into a lightweight, porous material. The controlled vapor-phase synthesis of fumed silica offers higher purity and specific surface properties, whereas perlite's thermal expansion process emphasizes lightweight insulation and bulk volume.

Physical Characteristics and Structure

Fumed silica features ultra-fine, spherical particles with a high surface area and low density, providing excellent viscosity and thixotropic properties for building material formulations. Perlite consists of amorphous volcanic glass expanded by rapid heating, creating lightweight, porous, and thermally insulating particles with a rough texture. The microscopic structure of fumed silica results in a fluffy, powdery consistency, while perlite's cellular, granular structure enhances thermal insulation and fire resistance in construction applications.

Thermal Insulation Performance

Fumed silica provides superior thermal insulation due to its ultra-fine particle size and high surface area, creating a dense barrier that minimizes heat transfer. Perlite offers effective insulation by trapping air within its expanded, porous structure, but its larger particle size results in slightly lower thermal resistance compared to fumed silica. In applications requiring maximum thermal efficiency, fumed silica typically outperforms perlite, especially in thin-layer insulation systems.

Applications in Construction and Building Materials

Fumed silica enhances cement and concrete formulations by improving water retention, viscosity, and mechanical strength, making it ideal for high-performance coatings and sealants. Perlite is commonly used as a lightweight aggregate and insulation material in plaster, concrete blocks, and roofing due to its excellent thermal insulation and fire-resistant properties. Both materials contribute to energy efficiency and durability in modern construction but target different performance needs.

Environmental Impact and Sustainability

Fumed silica offers low environmental impact due to its efficient production process and high durability, reducing the need for frequent replacement in building materials. Perlite is a natural volcanic glass that is environmentally sustainable, biodegradable, and energy-efficient during mining and processing, but it has a higher embodied energy compared to fumed silica. Both materials contribute to sustainable building practices by improving insulation and reducing energy consumption in construction projects.

Cost Analysis: Fumed Silica vs Perlite

Fumed silica typically incurs higher costs due to its advanced manufacturing process and superior reinforcing properties, making it a premium additive in building materials. Perlite offers a more economical solution, widely used as an insulating aggregate and lightweight filler in construction, which significantly reduces overall material expenses. Choosing between fumed silica and perlite depends on balancing performance benefits against budget constraints in building projects.

Handling, Safety, and Storage Considerations

Fumed silica requires careful handling due to its fine, dust-like particles that can cause respiratory irritation, necessitating the use of protective masks and gloves, along with storage in tightly sealed containers to prevent moisture absorption. Perlite, being lightweight and non-toxic, poses minimal health risks but can generate dust, so adequate ventilation and dust control measures are recommended during handling and storage in dry, cool environments. Both materials must be stored away from high humidity and contaminants to maintain their effectiveness and ensure worker safety on construction sites.

Choosing the Right Material for Your Project

Fumed silica offers superb reinforcement and thickening properties, making it ideal for high-performance coatings and sealants, while perlite excels in insulation and lightweight aggregate applications due to its porous structure. Selecting between fumed silica and perlite depends on project requirements such as thermal performance, weight considerations, and mechanical strength. For thermal insulation and fire resistance, perlite is preferred, whereas fumed silica is better suited for enhancing viscosity and durability in advanced material formulations.

Fumed Silica vs Perlite Infographic

productdif.com

productdif.com