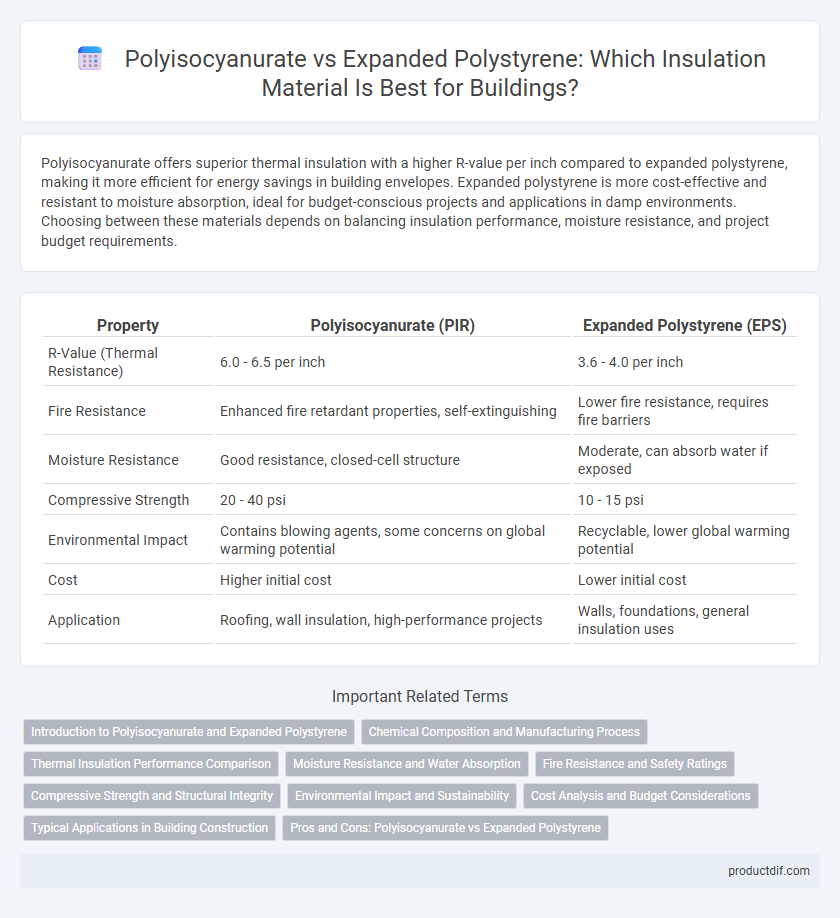

Polyisocyanurate offers superior thermal insulation with a higher R-value per inch compared to expanded polystyrene, making it more efficient for energy savings in building envelopes. Expanded polystyrene is more cost-effective and resistant to moisture absorption, ideal for budget-conscious projects and applications in damp environments. Choosing between these materials depends on balancing insulation performance, moisture resistance, and project budget requirements.

Table of Comparison

| Property | Polyisocyanurate (PIR) | Expanded Polystyrene (EPS) |

|---|---|---|

| R-Value (Thermal Resistance) | 6.0 - 6.5 per inch | 3.6 - 4.0 per inch |

| Fire Resistance | Enhanced fire retardant properties, self-extinguishing | Lower fire resistance, requires fire barriers |

| Moisture Resistance | Good resistance, closed-cell structure | Moderate, can absorb water if exposed |

| Compressive Strength | 20 - 40 psi | 10 - 15 psi |

| Environmental Impact | Contains blowing agents, some concerns on global warming potential | Recyclable, lower global warming potential |

| Cost | Higher initial cost | Lower initial cost |

| Application | Roofing, wall insulation, high-performance projects | Walls, foundations, general insulation uses |

Introduction to Polyisocyanurate and Expanded Polystyrene

Polyisocyanurate (PIR) is a rigid foam insulation known for its high thermal resistance, typically offering R-values between 6.0 and 6.5 per inch, making it ideal for energy-efficient construction. Expanded polystyrene (EPS) provides cost-effective insulation with an R-value around 4.0 per inch and is commonly used in walls and roofing due to its moisture resistance and lightweight properties. Both materials contribute to building envelope performance but differ significantly in fire resistance, thermal conductivity, and environmental impact.

Chemical Composition and Manufacturing Process

Polyisocyanurate (PIR) is a rigid foam insulation material produced through the reaction of polyol and methylene diphenyl diisocyanate (MDI) with a higher isocyanate index, resulting in a polymer structure with enhanced thermal stability and fire resistance. Expanded polystyrene (EPS) is manufactured by polymerizing styrene monomers and expanding the beads with steam, creating a closed-cell foam that offers lightweight thermal insulation but lower flame resistance. The chemical composition of PIR includes urethane and isocyanurate linkages, providing superior insulation performance, whereas EPS relies on polystyrene's hydrocarbon structure, impacting its mechanical and thermal properties.

Thermal Insulation Performance Comparison

Polyisocyanurate (PIR) insulation offers a superior thermal resistance with R-values typically ranging from 6.0 to 6.5 per inch compared to expanded polystyrene (EPS), which generally provides R-values around 3.6 to 4.0 per inch. PIR's closed-cell structure enhances its thermal insulation performance, reducing heat transfer more effectively than EPS's bead-based composition. This makes polyisocyanurate a preferred choice for energy-efficient building envelopes where high insulation value and space-saving are critical.

Moisture Resistance and Water Absorption

Polyisocyanurate insulation offers superior moisture resistance compared to expanded polystyrene, exhibiting lower water absorption rates that enhance its durability in damp environments. Expanded polystyrene typically absorbs more water, which can compromise its thermal performance and structural integrity over time. Selecting polyisocyanurate for building envelopes ensures better preservation of insulation properties in high-humidity conditions.

Fire Resistance and Safety Ratings

Polyisocyanurate (PIR) insulation offers superior fire resistance compared to expanded polystyrene (EPS), with higher limiting oxygen index (LOI) values and better performance in ASTM E84 flame spread tests. PIR typically achieves Class A fire ratings, indicating excellent flame retardancy and low smoke development, while EPS is often limited to Class B or C ratings due to its higher combustibility. Building codes favor PIR in applications requiring stringent fire safety standards, making it the preferred choice for insulation in commercial and residential structures with enhanced fire protection demands.

Compressive Strength and Structural Integrity

Polyisocyanurate insulation offers superior compressive strength compared to expanded polystyrene, typically ranging from 20 to 40 psi versus EPS's 10 to 15 psi. This higher compressive strength ensures enhanced structural integrity in building applications where load-bearing capacity is critical. Polyisocyanurate's rigid foam structure also maintains durability under long-term stress, reducing deformation and potential structural failure risks.

Environmental Impact and Sustainability

Polyisocyanurate (PIR) insulation offers superior thermal performance with a higher R-value per inch compared to expanded polystyrene (EPS), reducing overall energy consumption in buildings. PIR typically has a more complex manufacturing process involving petrochemical derivatives, resulting in higher embodied energy and potential environmental concerns related to blowing agents. EPS, made from polystyrene beads, is often more recyclable and has a lower embodied carbon footprint, making it a preferable choice for projects prioritizing sustainability and reduced environmental impact.

Cost Analysis and Budget Considerations

Polyisocyanurate insulation typically presents a higher upfront cost compared to expanded polystyrene (EPS), but its superior thermal efficiency can lead to greater long-term energy savings and reduced HVAC expenses. EPS offers a lower initial investment, making it attractive for projects with tight budgets; however, its lower R-value may increase overall energy costs over time. Budget considerations should weigh both the initial material cost and lifecycle performance to determine the most cost-effective insulation solution for specific building requirements.

Typical Applications in Building Construction

Polyisocyanurate insulation is commonly used for roof decking, wall panels, and industrial refrigeration due to its high thermal resistance and fire-retardant properties, making it ideal for energy-efficient commercial buildings. Expanded polystyrene (EPS) is frequently utilized in exterior insulation and finish systems (EIFS), foundation walls, and insulated concrete forms because of its moisture resistance and cost-effectiveness. Both materials contribute significantly to building envelope performance, but polyisocyanurate is favored where superior fire safety and insulation values are critical.

Pros and Cons: Polyisocyanurate vs Expanded Polystyrene

Polyisocyanurate insulation offers a higher R-value per inch compared to expanded polystyrene (EPS), providing superior thermal resistance and fire retardancy, which enhances energy efficiency and safety in building applications. Expanded polystyrene is more cost-effective and moisture-resistant, making it suitable for below-grade or damp environments despite its lower R-value and vulnerability to flame spread without additives. Choosing between polyisocyanurate and EPS depends on specific project requirements, including thermal performance, budget constraints, and environmental exposure.

polyisocyanurate vs expanded polystyrene Infographic

productdif.com

productdif.com