Hot-dip galvanizing offers superior corrosion resistance by dipping steel into molten zinc, creating a durable, long-lasting protective layer ideal for structural building materials. Powder coating provides a decorative finish with a wide range of colors and textures while also enhancing corrosion resistance through electrostatically applied dry powder baked onto the surface. Comparing the two, hot-dip galvanizing excels in heavy-duty environments requiring robust protection, whereas powder coating is preferred for aesthetic versatility and moderate protection in architectural applications.

Table of Comparison

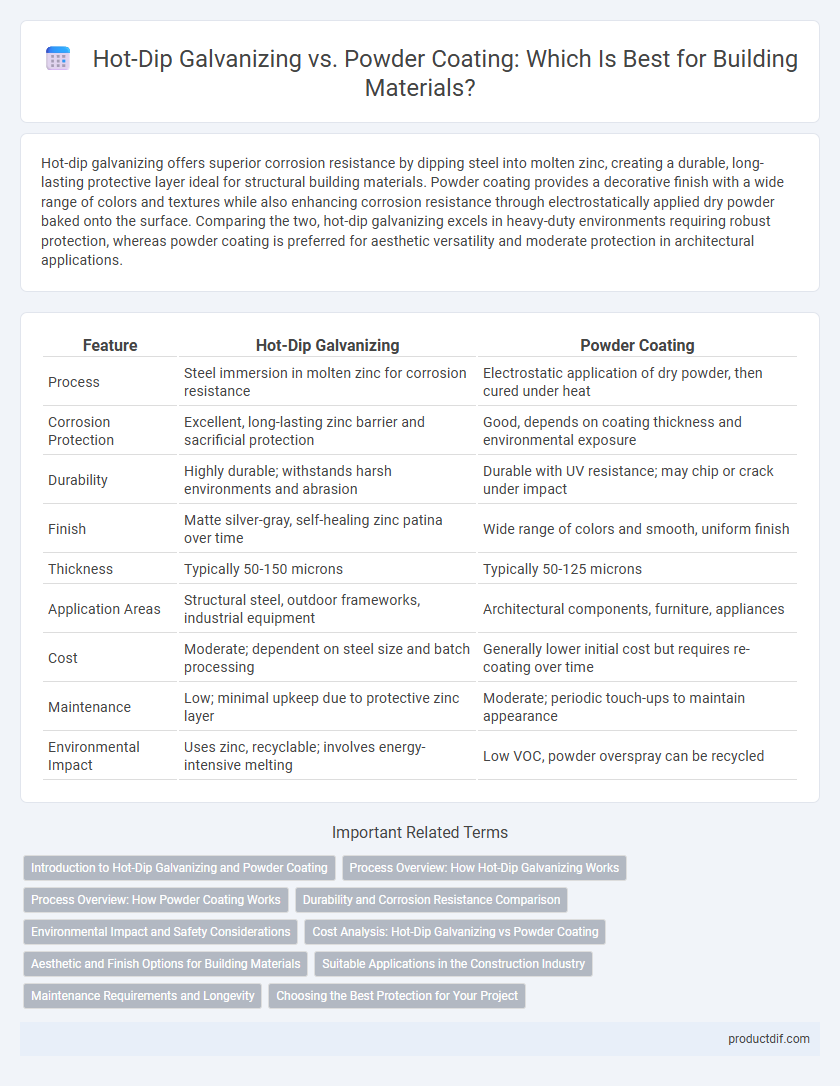

| Feature | Hot-Dip Galvanizing | Powder Coating |

|---|---|---|

| Process | Steel immersion in molten zinc for corrosion resistance | Electrostatic application of dry powder, then cured under heat |

| Corrosion Protection | Excellent, long-lasting zinc barrier and sacrificial protection | Good, depends on coating thickness and environmental exposure |

| Durability | Highly durable; withstands harsh environments and abrasion | Durable with UV resistance; may chip or crack under impact |

| Finish | Matte silver-gray, self-healing zinc patina over time | Wide range of colors and smooth, uniform finish |

| Thickness | Typically 50-150 microns | Typically 50-125 microns |

| Application Areas | Structural steel, outdoor frameworks, industrial equipment | Architectural components, furniture, appliances |

| Cost | Moderate; dependent on steel size and batch processing | Generally lower initial cost but requires re-coating over time |

| Maintenance | Low; minimal upkeep due to protective zinc layer | Moderate; periodic touch-ups to maintain appearance |

| Environmental Impact | Uses zinc, recyclable; involves energy-intensive melting | Low VOC, powder overspray can be recycled |

Introduction to Hot-Dip Galvanizing and Powder Coating

Hot-dip galvanizing involves immersing steel in molten zinc to create a durable, corrosion-resistant coating that extends the lifespan of structural components. Powder coating applies a dry, electrostatically charged powder to a metal surface, which is then cured under heat to form a tough, protective finish with excellent aesthetic appeal. Both methods enhance metal durability, but hot-dip galvanizing offers superior corrosion protection for outdoor and industrial environments, while powder coating provides versatile color options and smooth surface finishes.

Process Overview: How Hot-Dip Galvanizing Works

Hot-dip galvanizing involves immersing steel or iron components into a bath of molten zinc heated to approximately 450degC, forming a robust, corrosion-resistant alloy coating. The zinc coating metallurgically bonds to the base metal, creating a durable barrier that protects against rust and environmental damage for decades. This process produces a thick, uniform coating that is especially effective for structural steel, outdoor infrastructure, and heavy-duty applications.

Process Overview: How Powder Coating Works

Powder coating involves applying a dry powder made of finely ground particles of pigment and resin to a metal surface using electrostatic spray deposition. The coated object is then cured in an oven at high temperatures, typically between 160-210degC (320-410degF), causing the powder to melt and form a smooth, durable finish. This process provides superior resistance to corrosion, chipping, and fading compared to traditional liquid paint methods.

Durability and Corrosion Resistance Comparison

Hot-dip galvanizing provides superior corrosion resistance by coating steel with a thick layer of zinc that sacrificially protects the metal from rust, making it ideal for harsh outdoor environments. Powder coating offers a durable, aesthetic finish with strong resistance to chipping, scratching, and fading, but may deteriorate faster when exposed to UV rays and moisture compared to hot-dip galvanizing. For long-term durability in aggressive conditions, hot-dip galvanizing generally outperforms powder coating, especially when combined with a topcoat for enhanced protection.

Environmental Impact and Safety Considerations

Hot-dip galvanizing provides long-term corrosion protection by applying a zinc coating that prevents rust, minimizing the need for frequent repainting and reducing environmental waste. Powder coating uses electrostatically applied dry powders cured under heat, creating a durable, chemical-free finish with low VOC emissions, contributing to improved air quality and worker safety. Both methods reduce hazardous material exposure but powder coating offers better control over emissions, while hot-dip galvanizing involves handling molten zinc, requiring strict safety protocols to prevent thermal burns and inhalation risks.

Cost Analysis: Hot-Dip Galvanizing vs Powder Coating

Hot-dip galvanizing generally incurs lower long-term costs due to its superior durability and minimal maintenance requirements, making it cost-effective for large-scale or outdoor steel structures. Powder coating often involves higher upfront expenses and periodic reapplication, increasing lifecycle costs, especially in harsh environments. Cost analysis must account for environmental exposure, expected service life, and frequency of maintenance to determine the most economical protective coating.

Aesthetic and Finish Options for Building Materials

Hot-dip galvanizing provides a durable, corrosion-resistant zinc coating with a matte, metallic finish ideal for industrial or utilitarian aesthetics in building materials. Powder coating offers a versatile range of colors, textures, and gloss levels, enabling customized and vibrant finishes that enhance architectural design. Combining both methods can optimize protection and aesthetic appeal, balancing longevity with design flexibility.

Suitable Applications in the Construction Industry

Hot-dip galvanizing is ideal for structural steel components in outdoor environments due to its superior corrosion resistance and durability against harsh weather conditions. Powder coating is preferred for architectural elements, such as window frames and decorative panels, where aesthetic appeal and a wide color range are important. Combining both methods is common for projects requiring enhanced protection and visual finish, especially in commercial building facades and infrastructure projects.

Maintenance Requirements and Longevity

Hot-dip galvanizing offers superior corrosion resistance with minimal maintenance, often lasting 40 to 50 years without significant upkeep, making it ideal for harsh outdoor environments. Powder coating requires periodic inspection and touch-ups to maintain its protective finish, typically lasting 10 to 20 years depending on exposure and quality of application. Both methods enhance durability, but hot-dip galvanizing provides a longer-lasting, low-maintenance solution for structural steel components.

Choosing the Best Protection for Your Project

Hot-dip galvanizing offers superior corrosion resistance by coating steel with a thick layer of zinc, making it ideal for outdoor structures exposed to harsh weather conditions. Powder coating provides a durable, aesthetically customizable finish that resists chipping and fading, suitable for decorative or indoor applications. Selecting the best protection depends on project requirements like environmental exposure, desired lifespan, and visual appeal.

Hot-Dip Galvanizing vs Powder Coating Infographic

productdif.com

productdif.com