Laminated Veneer Lumber (LVL) offers superior dimensional stability and consistent strength due to its multiple thin wood veneers bonded under heat and pressure, making it ideal for beams and headers. Parallel Strand Lumber (PSL) is engineered from long veneer strands aligned parallel, providing exceptional load-bearing capacity and resistance to warping, suitable for heavy structural applications. Choosing between LVL and PSL depends on specific project requirements, with LVL favored for precision and PSL for maximum strength.

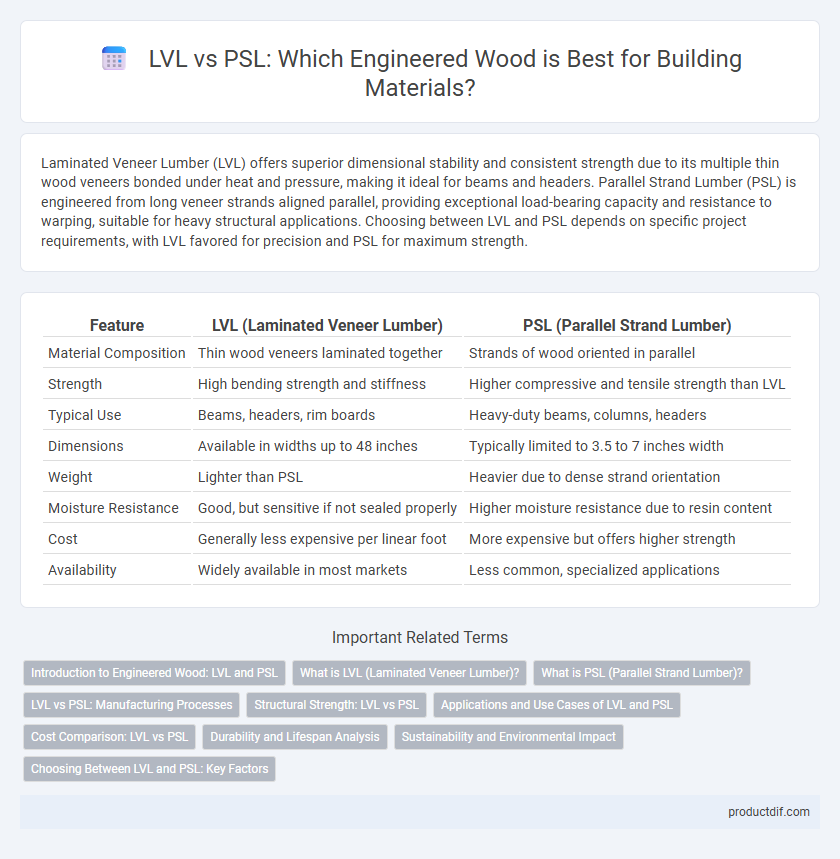

Table of Comparison

| Feature | LVL (Laminated Veneer Lumber) | PSL (Parallel Strand Lumber) |

|---|---|---|

| Material Composition | Thin wood veneers laminated together | Strands of wood oriented in parallel |

| Strength | High bending strength and stiffness | Higher compressive and tensile strength than LVL |

| Typical Use | Beams, headers, rim boards | Heavy-duty beams, columns, headers |

| Dimensions | Available in widths up to 48 inches | Typically limited to 3.5 to 7 inches width |

| Weight | Lighter than PSL | Heavier due to dense strand orientation |

| Moisture Resistance | Good, but sensitive if not sealed properly | Higher moisture resistance due to resin content |

| Cost | Generally less expensive per linear foot | More expensive but offers higher strength |

| Availability | Widely available in most markets | Less common, specialized applications |

Introduction to Engineered Wood: LVL and PSL

Laminated Veneer Lumber (LVL) and Parallel Strand Lumber (PSL) are advanced engineered wood products designed for high-strength structural applications. LVL is manufactured by bonding together thin wood veneers with adhesives, offering excellent uniformity and load-bearing capacity. PSL is created by compressing long wood strands with adhesive, producing a dense material ideal for heavy-duty beams and columns in construction.

What is LVL (Laminated Veneer Lumber)?

Laminated Veneer Lumber (LVL) is an engineered wood product made by bonding thin wood veneers together with waterproof adhesive, creating a strong and consistent structural material. Known for its high strength-to-weight ratio, LVL is commonly used in beams, headers, and other load-bearing applications in residential and commercial construction. Its uniform density and dimensional stability make it a preferred choice over traditional solid lumber for long spans and heavy loads.

What is PSL (Parallel Strand Lumber)?

Parallel Strand Lumber (PSL) is an engineered wood product made from long veneer strands glued together with moisture-resistant adhesives under high pressure. It offers exceptional strength, stiffness, and dimensional stability, making it ideal for heavy-load structural applications such as beams, headers, and columns. Compared to Laminated Veneer Lumber (LVL), PSL provides superior load-carrying capacity and resistance to warping due to its continuous strand orientation.

LVL vs PSL: Manufacturing Processes

LVL (Laminated Veneer Lumber) is produced by bonding thin wood veneers together under heat and pressure with adhesives, creating strong, uniform sheets. PSL (Parallel Strand Lumber) manufacturing involves aligning long, continuous strands of wood coated with resin and compressing them into structural beams, resulting in high strength and stiffness. The key difference lies in LVL's layered veneer approach versus PSL's strand alignment, affecting their load-bearing performance and application suitability.

Structural Strength: LVL vs PSL

Laminated Veneer Lumber (LVL) offers superior uniformity and consistent strength due to its layered veneer construction, making it ideal for long spans and heavy loads in structural applications. Parallel Strand Lumber (PSL) provides higher compressive strength and excellent dimensional stability, often used in columns and beams requiring substantial load-bearing capacity. While LVL excels in bending resistance, PSL outperforms in axial load scenarios, influencing material selection based on project-specific structural demands.

Applications and Use Cases of LVL and PSL

LVL (Laminated Veneer Lumber) is commonly used in long-span beams, headers, rim boards, and edge-forming materials due to its high strength-to-weight ratio and consistent performance. PSL (Parallel Strand Lumber) is ideal for heavy-duty structural applications like columns, beams, and post-and-beam frameworks where exceptional load-bearing capacity and dimensional stability are critical. Both LVL and PSL are favored in residential and commercial construction for framing, but PSL excels in areas demanding superior compression strength and durability.

Cost Comparison: LVL vs PSL

LVL (Laminated Veneer Lumber) typically costs less per linear foot compared to PSL (Parallel Strand Lumber) due to differences in manufacturing processes and material usage. PSL offers higher strength and load-bearing capacity, which can justify its higher price in structural applications requiring greater durability. Project budgets often favor LVL for moderate load requirements, while PSL is selected for premium structural performance despite its increased cost.

Durability and Lifespan Analysis

Laminated Veneer Lumber (LVL) offers superior resistance to moisture and fungal decay due to its thin veneer layers and uniform adhesive application, resulting in enhanced durability compared to Parallel Strand Lumber (PSL). PSL, composed of long wood strands bonded with resin, provides high compressive strength but may be more susceptible to delamination under prolonged moisture exposure. In lifespan analysis, LVL generally outperforms PSL in environments with variable humidity levels, delivering extended structural integrity and reduced maintenance over time.

Sustainability and Environmental Impact

LVL (Laminated Veneer Lumber) and PSL (Parallel Strand Lumber) both offer sustainable alternatives to traditional solid wood, with LVL typically using thinner wood veneers that maximize resource efficiency and reduce waste. PSL is engineered from long strands of wood, often sourced from fast-growing species, promoting sustainable forestry by utilizing smaller, less valuable trees. Both materials provide lower carbon footprints and improved material yield, contributing significantly to environmentally responsible construction practices.

Choosing Between LVL and PSL: Key Factors

Choosing between Laminated Veneer Lumber (LVL) and Parallel Strand Lumber (PSL) depends on project-specific requirements such as load capacity, dimensional stability, and cost-efficiency. LVL offers superior strength-to-weight ratio and is ideal for long spans and heavy loads, while PSL provides consistent performance with better resistance to twisting and is suited for applications requiring thicker beams. Evaluating factors like structural demands, environmental conditions, and budget constraints ensures optimal selection of engineered wood products.

LVL vs PSL Infographic

productdif.com

productdif.com