Insulated Concrete Forms (ICFs) provide superior thermal insulation compared to traditional concrete, significantly reducing energy costs in buildings. ICFs combine the strength of concrete with the insulating properties of foam, offering enhanced durability and soundproofing. Traditional concrete lacks this insulation capability, often requiring additional materials to meet energy efficiency standards.

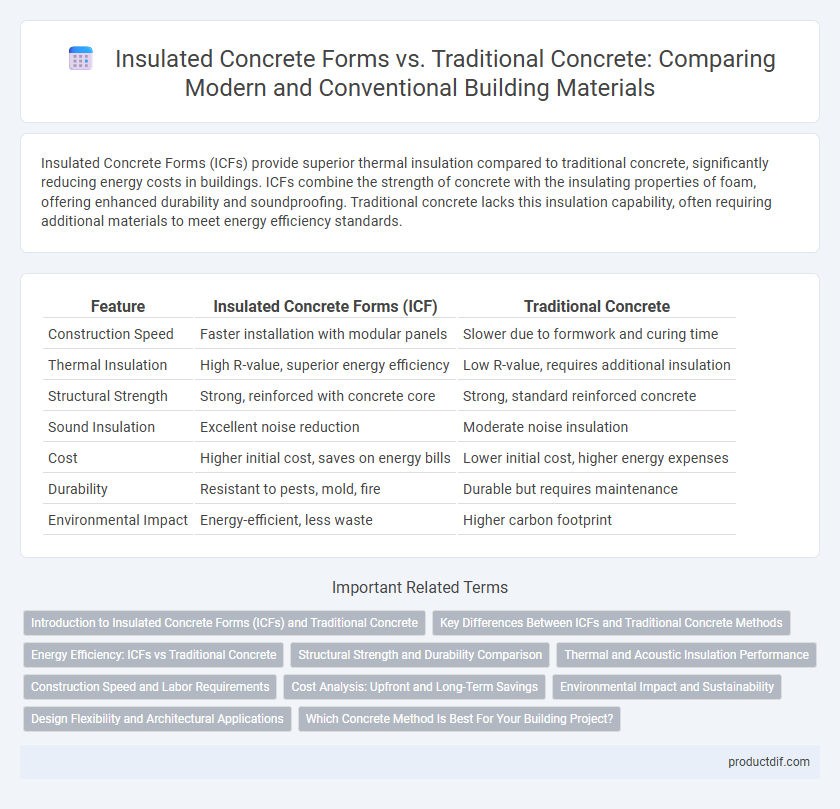

Table of Comparison

| Feature | Insulated Concrete Forms (ICF) | Traditional Concrete |

|---|---|---|

| Construction Speed | Faster installation with modular panels | Slower due to formwork and curing time |

| Thermal Insulation | High R-value, superior energy efficiency | Low R-value, requires additional insulation |

| Structural Strength | Strong, reinforced with concrete core | Strong, standard reinforced concrete |

| Sound Insulation | Excellent noise reduction | Moderate noise insulation |

| Cost | Higher initial cost, saves on energy bills | Lower initial cost, higher energy expenses |

| Durability | Resistant to pests, mold, fire | Durable but requires maintenance |

| Environmental Impact | Energy-efficient, less waste | Higher carbon footprint |

Introduction to Insulated Concrete Forms (ICFs) and Traditional Concrete

Insulated Concrete Forms (ICFs) consist of hollow foam blocks or panels that are stacked and filled with reinforced concrete, providing superior thermal insulation and energy efficiency compared to traditional concrete methods. Traditional concrete involves pouring mixed concrete into formwork, which offers structural strength but lacks the integrated insulation properties found in ICFs. ICF construction combines the durability of concrete with the insulating benefits of rigid foam, resulting in enhanced energy performance, soundproofing, and reduced thermal bridging.

Key Differences Between ICFs and Traditional Concrete Methods

Insulated Concrete Forms (ICFs) provide superior thermal insulation and energy efficiency compared to traditional concrete methods, incorporating foam blocks that reduce heat transfer and improve indoor comfort. ICF construction features faster assembly with interlocking forms that remain in place as permanent insulation, while traditional concrete relies on removable molds and offers less inherent insulation. The enhanced durability and soundproofing qualities of ICFs distinguish them from conventional concrete, which typically requires additional materials for thermal and acoustic performance.

Energy Efficiency: ICFs vs Traditional Concrete

Insulated Concrete Forms (ICFs) provide superior energy efficiency compared to traditional concrete due to their integrated insulation layers, which significantly reduce thermal bridging and heat loss. The high R-value of ICF walls enhances indoor temperature stability, lowering heating and cooling costs by up to 50% in various climates. Traditional concrete lacks this continuous insulation, leading to higher energy consumption and less effective thermal performance in buildings.

Structural Strength and Durability Comparison

Insulated Concrete Forms (ICFs) provide superior structural strength through reinforced concrete cores combined with rigid insulation, resulting in enhanced load-bearing capacity and resistance to natural disasters compared to traditional concrete blocks. The continuous insulation in ICFs reduces thermal bridging and improves moisture resistance, significantly increasing durability and lifespan under harsh environmental conditions. Traditional concrete, while robust in compression, often requires supplemental insulation and waterproofing to match the long-term performance and energy efficiency of ICF systems.

Thermal and Acoustic Insulation Performance

Insulated Concrete Forms (ICFs) offer superior thermal insulation with R-values typically ranging from 20 to 50, significantly reducing energy consumption compared to Traditional Concrete walls, which have R-values around 1 to 2. ICFs also provide enhanced acoustic insulation, effectively minimizing noise transmission due to their composite structure of concrete and foam insulation. Traditional Concrete, while strong and durable, lacks the integrated insulation properties of ICFs, resulting in higher energy costs and less soundproofing performance.

Construction Speed and Labor Requirements

Insulated Concrete Forms (ICFs) significantly reduce construction time by combining formwork and insulation into a single step, minimizing the need for separate installations. Labor requirements are also lower with ICFs since they are lightweight, easy to handle, and require fewer specialized skills compared to traditional concrete forms. Traditional concrete often demands more extensive labor for form setup, insulation, and curing processes, which extends project timelines.

Cost Analysis: Upfront and Long-Term Savings

Insulated Concrete Forms (ICFs) typically have a higher upfront cost compared to traditional concrete due to specialized materials and installation techniques. However, ICFs provide significant long-term savings through superior energy efficiency, reduced utility bills, and decreased maintenance expenses. Over the building's lifespan, these savings often offset initial investments, making ICFs a cost-effective solution for sustainable construction.

Environmental Impact and Sustainability

Insulated Concrete Forms (ICFs) offer superior environmental benefits compared to traditional concrete due to their enhanced energy efficiency and reduced carbon footprint during both construction and building operation. ICFs utilize expanded polystyrene insulation, which significantly improves thermal performance, lowering heating and cooling energy demands and thereby reducing greenhouse gas emissions over the building's lifecycle. Traditional concrete production generates high CO2 emissions from cement manufacturing, whereas ICF systems contribute to sustainable building practices by minimizing material waste and improving overall energy conservation.

Design Flexibility and Architectural Applications

Insulated Concrete Forms (ICFs) offer superior design flexibility compared to traditional concrete by allowing seamless integration of complex architectural shapes and curves without compromising insulation performance. ICFs provide enhanced thermal efficiency and soundproofing, making them ideal for energy-efficient buildings with diverse architectural features such as vaulted ceilings and expansive window openings. Traditional concrete, while robust and cost-effective, is limited in customization and typically requires additional insulation materials to meet modern energy codes.

Which Concrete Method Is Best For Your Building Project?

Insulated Concrete Forms (ICFs) offer superior energy efficiency, enhanced thermal insulation, and faster construction compared to Traditional Concrete, making them ideal for sustainable building projects and improved indoor comfort. Traditional Concrete remains a cost-effective choice with proven durability and widespread availability, suitable for projects prioritizing budget and straightforward application. Evaluating project requirements, climate considerations, and long-term performance goals determines whether ICFs or Traditional Concrete best aligns with your construction needs.

Insulated Concrete Forms vs Traditional Concrete Infographic

productdif.com

productdif.com