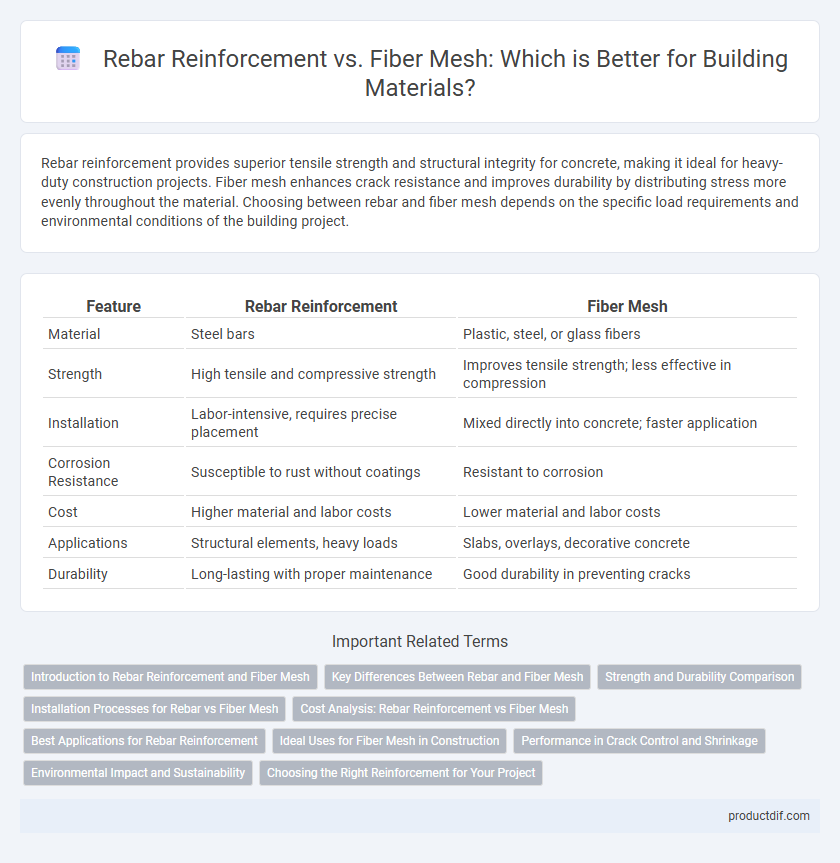

Rebar reinforcement provides superior tensile strength and structural integrity for concrete, making it ideal for heavy-duty construction projects. Fiber mesh enhances crack resistance and improves durability by distributing stress more evenly throughout the material. Choosing between rebar and fiber mesh depends on the specific load requirements and environmental conditions of the building project.

Table of Comparison

| Feature | Rebar Reinforcement | Fiber Mesh |

|---|---|---|

| Material | Steel bars | Plastic, steel, or glass fibers |

| Strength | High tensile and compressive strength | Improves tensile strength; less effective in compression |

| Installation | Labor-intensive, requires precise placement | Mixed directly into concrete; faster application |

| Corrosion Resistance | Susceptible to rust without coatings | Resistant to corrosion |

| Cost | Higher material and labor costs | Lower material and labor costs |

| Applications | Structural elements, heavy loads | Slabs, overlays, decorative concrete |

| Durability | Long-lasting with proper maintenance | Good durability in preventing cracks |

Introduction to Rebar Reinforcement and Fiber Mesh

Rebar reinforcement consists of steel bars embedded in concrete to improve tensile strength and structural integrity, making it essential for heavy-load-bearing constructions such as bridges and high-rise buildings. Fiber mesh reinforcement involves the integration of synthetic or steel fibers throughout the concrete mix, enhancing crack resistance and durability for applications like slabs, pavements, and industrial floors. Both techniques optimize concrete performance, with rebar providing targeted reinforcement and fiber mesh offering uniform stress distribution.

Key Differences Between Rebar and Fiber Mesh

Rebar reinforcement consists of steel bars that provide high tensile strength and structural support in concrete, essential for heavy-load-bearing applications such as foundations and beams. Fiber mesh is composed of synthetic or steel fibers distributed uniformly throughout the concrete mix, enhancing crack resistance and surface durability but offering less overall structural strength. While rebar improves load-bearing capacity and prevents major structural failures, fiber mesh primarily controls shrinkage cracks and reduces micro-cracking in slabs and pavements.

Strength and Durability Comparison

Rebar reinforcement offers superior tensile strength and load-bearing capacity compared to fiber mesh, making it ideal for structural applications requiring high durability. Fiber mesh improves crack resistance and reduces shrinkage in concrete but lacks the robust tensile strength of steel rebar. For projects demanding maximum structural integrity and long-term durability, rebar remains the preferred choice due to its enhanced mechanical performance under stress.

Installation Processes for Rebar vs Fiber Mesh

Rebar reinforcement installation involves precise placement and tying of steel bars within concrete forms, requiring skilled labor and time-intensive preparation to ensure structural integrity. Fiber mesh, made of synthetic or steel fibers, is mixed directly into the concrete, simplifying the installation process by eliminating the need for positioning and securing separate reinforcing elements. This integration speeds up construction timelines and reduces labor costs while providing distributed crack resistance throughout the concrete slab.

Cost Analysis: Rebar Reinforcement vs Fiber Mesh

Rebar reinforcement typically involves higher material and labor costs due to its weight and installation complexity compared to fiber mesh, which offers a cost-effective alternative with easier handling and faster application. Fiber mesh reduces overall expenses by minimizing labor time and decreasing the need for additional reinforcement in slabs and concrete structures, making it ideal for large-scale projects focused on budget efficiency. Evaluating project-specific requirements, including load-bearing capacity and structural integrity, is essential to determine the most cost-efficient reinforcement choice between rebar and fiber mesh.

Best Applications for Rebar Reinforcement

Rebar reinforcement is ideal for structural applications requiring high tensile strength and load-bearing capacity, such as foundations, beams, and columns in concrete construction. It provides superior resistance to cracking and enhances the durability of concrete in large-scale infrastructure projects like bridges and highways. Rebar is preferred over fiber mesh when precise engineering standards and heavy-duty reinforcement are critical for safety and longevity.

Ideal Uses for Fiber Mesh in Construction

Fiber mesh is ideal for concrete applications requiring enhanced crack resistance and durability, such as slabs, sidewalks, driveways, and residential floors. It distributes tensile strength uniformly across the concrete, reducing shrinkage cracks and improving surface integrity without the need for extensive labor. Fiber mesh is especially effective in thin or lightly reinforced concrete sections where traditional rebar reinforcement would be impractical or cost-prohibitive.

Performance in Crack Control and Shrinkage

Rebar reinforcement offers superior structural strength by effectively distributing tensile forces and controlling large cracks, making it ideal for heavy-load applications. Fiber mesh enhances crack control by uniformly reducing micro-cracking and shrinkage throughout the concrete matrix, improving durability and surface finish. Combining rebar with fiber mesh optimizes crack resistance and minimizes shrinkage-related damage, extending the lifespan of concrete structures.

Environmental Impact and Sustainability

Rebar reinforcement, typically made from steel, has a higher embodied energy and carbon footprint due to mining, smelting, and transportation processes, whereas fiber mesh, often composed of synthetic or recycled polymers, offers a lower environmental impact with reduced raw material consumption and enhanced durability. Fiber mesh contributes to sustainability by reducing the need for traditional steel rebar, lowering the overall weight of concrete structures, and facilitating energy-efficient construction methods. Rebar's recyclability and long lifespan partially offset its environmental costs, but fiber mesh's potential for lower waste generation and improved concrete crack resistance makes it a more eco-friendly option in many applications.

Choosing the Right Reinforcement for Your Project

Rebar reinforcement provides superior tensile strength and is ideal for structural elements like beams and columns requiring heavy load-bearing capacity. Fiber mesh offers increased crack resistance and improved durability, making it suitable for concrete slabs and surfaces exposed to environmental stress. Selecting the right reinforcement depends on the project's structural demands, load requirements, and desired finish quality.

Rebar Reinforcement vs Fiber Mesh Infographic

productdif.com

productdif.com