Thermal break building materials incorporate insulating barriers that reduce heat transfer, significantly enhancing energy efficiency and indoor comfort. Non-thermal break materials lack this barrier, often resulting in greater heat loss or gain and higher energy costs. Choosing thermal break materials is essential for improved thermal performance and sustainability in construction.

Table of Comparison

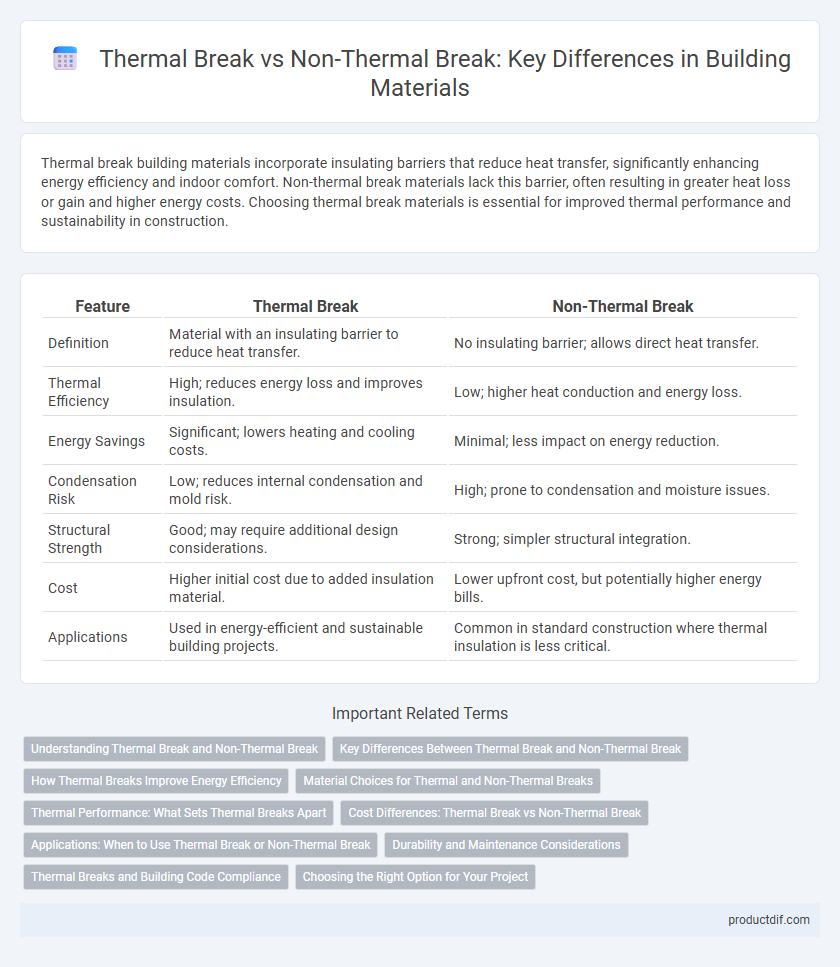

| Feature | Thermal Break | Non-Thermal Break |

|---|---|---|

| Definition | Material with an insulating barrier to reduce heat transfer. | No insulating barrier; allows direct heat transfer. |

| Thermal Efficiency | High; reduces energy loss and improves insulation. | Low; higher heat conduction and energy loss. |

| Energy Savings | Significant; lowers heating and cooling costs. | Minimal; less impact on energy reduction. |

| Condensation Risk | Low; reduces internal condensation and mold risk. | High; prone to condensation and moisture issues. |

| Structural Strength | Good; may require additional design considerations. | Strong; simpler structural integration. |

| Cost | Higher initial cost due to added insulation material. | Lower upfront cost, but potentially higher energy bills. |

| Applications | Used in energy-efficient and sustainable building projects. | Common in standard construction where thermal insulation is less critical. |

Understanding Thermal Break and Non-Thermal Break

Thermal break materials incorporate insulating barriers, typically made of polyamide or polyurethane, to reduce heat transfer between interior and exterior surfaces, improving energy efficiency in windows, doors, and curtain walls. Non-thermal break materials lack this insulating barrier, allowing heat to pass through metal frames more readily, which can lead to higher thermal conductivity and energy loss. Understanding the distinction is crucial for selecting building materials that optimize thermal performance and reduce HVAC costs.

Key Differences Between Thermal Break and Non-Thermal Break

Thermal break materials incorporate a barrier, often made from polyurethane or polyamide, to reduce heat transfer through metal components in building envelopes, significantly enhancing energy efficiency and reducing condensation. Non-thermal break materials lack this insulating barrier, causing higher thermal conductivity and increased heat loss or gain, which can lead to higher energy costs and potential moisture problems. Choosing thermal break over non-thermal break systems is critical for improving building insulation performance and maintaining interior comfort.

How Thermal Breaks Improve Energy Efficiency

Thermal breaks in building materials significantly reduce heat transfer by creating a barrier between interior and exterior components, which minimizes thermal bridging and enhances insulation performance. This improvement in energy efficiency helps maintain consistent indoor temperatures, reducing the workload on heating and cooling systems and lowering energy bills. Buildings equipped with thermal breaks also experience less condensation and moisture buildup, contributing to improved durability and indoor air quality.

Material Choices for Thermal and Non-Thermal Breaks

Thermal break materials commonly include polyamide strips and foam insulation, designed to reduce heat transfer in aluminum frames by creating a barrier between interior and exterior surfaces. Non-thermal break components often utilize solid aluminum or steel, prioritizing structural strength over thermal efficiency but leading to higher heat conductivity. Selecting appropriate materials involves balancing energy efficiency needs with mechanical performance and cost considerations.

Thermal Performance: What Sets Thermal Breaks Apart

Thermal breaks significantly enhance thermal performance by reducing heat transfer through construction materials, creating a barrier that minimizes thermal bridging in building envelopes. Unlike non-thermal break materials, which allow heat to pass freely through metal or other conductive elements, thermal breaks incorporate insulating materials such as polyurethane or polyamide strips that disrupt heat flow. This results in improved energy efficiency, increased comfort, and reduced condensation risks in buildings.

Cost Differences: Thermal Break vs Non-Thermal Break

Thermal break materials typically incur higher initial costs compared to non-thermal break options due to advanced insulating components such as polyamide strips or polyurethane barriers incorporated to reduce heat transfer. Non-thermal break materials, often made of single-material metals like aluminum without insulation, offer lower upfront expenses but result in higher long-term energy consumption and potential condensation issues. Evaluating total cost of ownership reveals thermal break systems provide significant savings in heating and cooling bills despite their greater initial investment.

Applications: When to Use Thermal Break or Non-Thermal Break

Thermal break materials are essential in applications requiring superior insulation, such as windows, doors, and curtain walls in cold climates to reduce heat transfer and improve energy efficiency. Non-thermal break materials suit projects where thermal insulation is less critical, such as interior partitions or industrial structures without strict temperature control. Choosing between thermal break and non-thermal break depends on climate conditions, energy codes, and desired thermal performance.

Durability and Maintenance Considerations

Thermal break materials enhance durability by reducing thermal expansion and contraction, minimizing stress on structural components and preventing material fatigue over time. Non-thermal break materials often experience more pronounced temperature fluctuations, which can cause warping, cracking, and increased wear, leading to higher maintenance requirements. Choosing thermal break systems results in lower long-term maintenance costs and extended lifespan for building envelopes exposed to extreme temperature variations.

Thermal Breaks and Building Code Compliance

Thermal break materials significantly enhance energy efficiency by reducing heat transfer between building components, aligning with stringent building code requirements for insulation and energy conservation. Incorporating thermal breaks in window frames, curtain walls, and structural elements minimizes thermal bridging, helping structures meet or exceed standards such as ASHRAE 90.1 and the International Energy Conservation Code (IECC). Compliance with these codes not only improves occupant comfort but also contributes to sustainable building practices and reduced energy costs.

Choosing the Right Option for Your Project

Selecting between thermal break and non-thermal break materials depends on the project's insulation and energy efficiency requirements. Thermal break materials incorporate insulating barriers that reduce heat transfer, enhancing energy savings in building envelopes. Non-thermal break materials may be more cost-effective but typically offer lower thermal performance, making them suitable for non-critical applications.

Thermal Break vs Non-Thermal Break Infographic

productdif.com

productdif.com