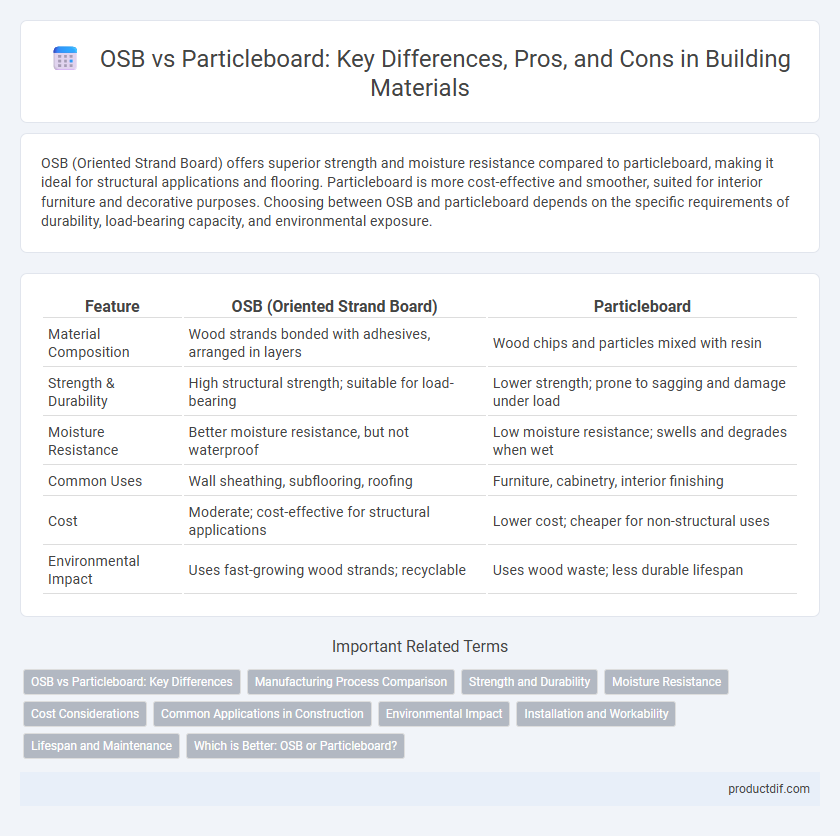

OSB (Oriented Strand Board) offers superior strength and moisture resistance compared to particleboard, making it ideal for structural applications and flooring. Particleboard is more cost-effective and smoother, suited for interior furniture and decorative purposes. Choosing between OSB and particleboard depends on the specific requirements of durability, load-bearing capacity, and environmental exposure.

Table of Comparison

| Feature | OSB (Oriented Strand Board) | Particleboard |

|---|---|---|

| Material Composition | Wood strands bonded with adhesives, arranged in layers | Wood chips and particles mixed with resin |

| Strength & Durability | High structural strength; suitable for load-bearing | Lower strength; prone to sagging and damage under load |

| Moisture Resistance | Better moisture resistance, but not waterproof | Low moisture resistance; swells and degrades when wet |

| Common Uses | Wall sheathing, subflooring, roofing | Furniture, cabinetry, interior finishing |

| Cost | Moderate; cost-effective for structural applications | Lower cost; cheaper for non-structural uses |

| Environmental Impact | Uses fast-growing wood strands; recyclable | Uses wood waste; less durable lifespan |

OSB vs Particleboard: Key Differences

Oriented Strand Board (OSB) offers superior strength and durability compared to particleboard, making it ideal for structural applications such as subflooring and roofing. OSB's layered strands provide better moisture resistance and load-bearing capacity, while particleboard tends to absorb water and deteriorate more quickly. The cost-effectiveness of particleboard suits interior, non-load-bearing uses, whereas OSB is preferred for areas requiring enhanced stability and longevity.

Manufacturing Process Comparison

OSB (Oriented Strand Board) is manufactured by layering strands of wood in specific orientations and bonding them with waterproof adhesives under heat and pressure, resulting in high strength and durability. Particleboard production involves compressing wood chips, sawdust, and resin into sheets, which typically offers lower strength and moisture resistance compared to OSB. The stratified structure of OSB provides better load distribution, making it more suitable for structural applications than the homogeneous composition of particleboard.

Strength and Durability

Oriented Strand Board (OSB) offers superior strength and durability compared to particleboard due to its layered wood strands bonded with strong adhesives, making it ideal for structural applications. Particleboard, composed of compressed wood particles and resin, has less load-bearing capacity and is more susceptible to moisture damage, reducing its longevity. OSB's enhanced rigidity and resistance to warping make it a preferred choice for flooring, roofing, and wall sheathing in construction projects.

Moisture Resistance

Oriented Strand Board (OSB) offers superior moisture resistance compared to particleboard, making it ideal for environments prone to humidity and occasional water exposure. OSB's structured layering of wood strands bound with waterproof adhesives enhances its durability against swelling and warping caused by moisture. Particleboard, composed of wood particles and resin, tends to absorb water quickly and degrade, reducing its suitability for moist or outdoor applications.

Cost Considerations

Oriented Strand Board (OSB) typically offers a more cost-effective solution compared to particleboard due to its durability and structural strength, which extends the lifespan of construction projects. Particleboard, while cheaper initially, often incurs higher replacement or maintenance costs because of its lower moisture resistance and susceptibility to wear. Evaluating long-term expenses reveals OSB as a financially advantageous choice for builders prioritizing budget efficiency and material performance.

Common Applications in Construction

Oriented Strand Board (OSB) is widely used for wall sheathing, roof decking, and subflooring due to its strength, moisture resistance, and structural integrity. Particleboard is common for interior applications such as cabinetry, furniture, and underlayment where load-bearing capacity is less critical. Builders prefer OSB in structural projects for durability, while particleboard suits cost-effective, non-structural finishes and surface coverings.

Environmental Impact

OSB (Oriented Strand Board) typically has a lower environmental impact compared to particleboard due to its use of whole wood strands arranged in layers, improving strength and reducing the need for adhesives. Particleboard often relies on formaldehyde-based resins, which can emit volatile organic compounds (VOCs) contributing to indoor air pollution. OSB's production process maximizes the use of fast-growing, smaller-diameter trees, promoting sustainable forestry and reducing deforestation pressures.

Installation and Workability

OSB (Oriented Strand Board) offers superior installation ease with its uniform thickness and strong structural integrity, allowing for precise cutting and fastening without splintering. Particleboard tends to be denser but more prone to chipping and swelling when exposed to moisture, complicating installation and requiring careful handling. Workability of OSB is enhanced by its moisture resistance and durability, making it preferable for construction projects demanding reliable performance during assembly.

Lifespan and Maintenance

Oriented Strand Board (OSB) generally offers a longer lifespan compared to particleboard due to its stronger, denser composition and better resistance to moisture. OSB requires less frequent maintenance since it is less prone to swelling, warping, or deterioration when exposed to humidity, unlike particleboard which often needs sealing or protective coatings to extend its usability. The durability and maintenance efficiency of OSB make it a preferred choice for structural applications where longevity and low upkeep are critical.

Which is Better: OSB or Particleboard?

Oriented Strand Board (OSB) offers superior strength, durability, and moisture resistance compared to particleboard, making it ideal for structural applications such as subflooring and wall sheathing. Particleboard is more cost-effective and smoother, often preferred for interior uses like cabinetry and furniture where heavy loads and moisture exposure are minimal. Choosing OSB ensures long-term stability and resilience, while particleboard suits budget-conscious, low-stress environments.

OSB vs Particleboard Infographic

productdif.com

productdif.com