Hot-dip galvanizing provides a thicker, more durable zinc coating compared to electroplating, offering superior corrosion resistance for building materials. Electroplating delivers a smoother finish and precise coating thickness but is generally less robust against harsh environmental exposure. Choosing between these methods depends on the project's durability requirements and aesthetic preferences.

Table of Comparison

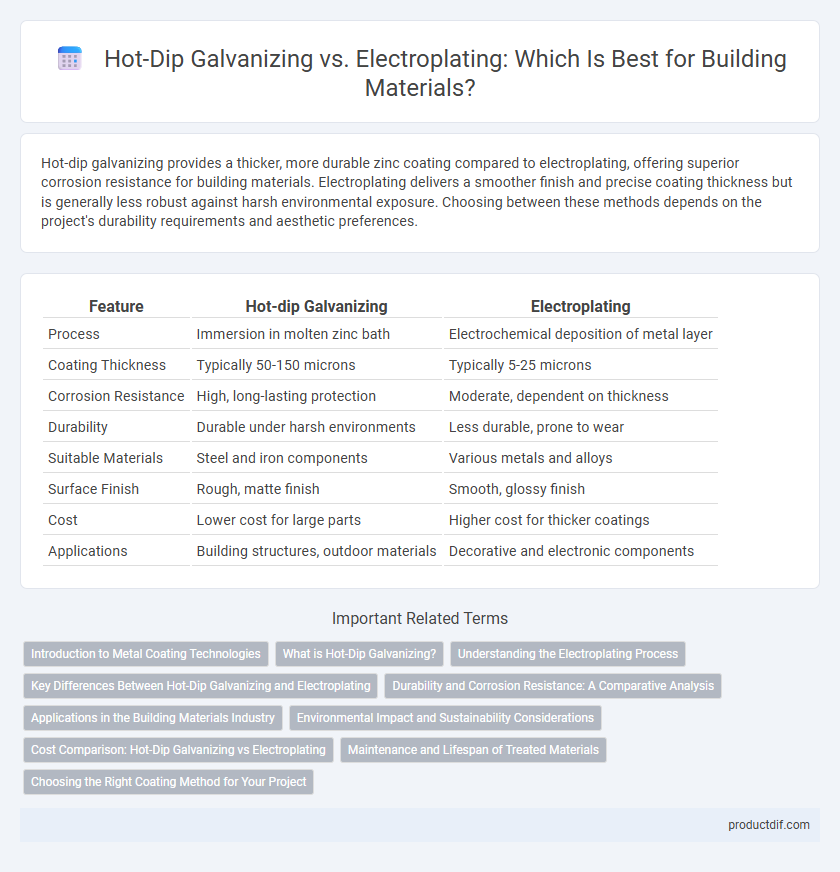

| Feature | Hot-dip Galvanizing | Electroplating |

|---|---|---|

| Process | Immersion in molten zinc bath | Electrochemical deposition of metal layer |

| Coating Thickness | Typically 50-150 microns | Typically 5-25 microns |

| Corrosion Resistance | High, long-lasting protection | Moderate, dependent on thickness |

| Durability | Durable under harsh environments | Less durable, prone to wear |

| Suitable Materials | Steel and iron components | Various metals and alloys |

| Surface Finish | Rough, matte finish | Smooth, glossy finish |

| Cost | Lower cost for large parts | Higher cost for thicker coatings |

| Applications | Building structures, outdoor materials | Decorative and electronic components |

Introduction to Metal Coating Technologies

Hot-dip galvanizing and electroplating are essential metal coating technologies used in building materials to enhance corrosion resistance and prolong structural lifespan. Hot-dip galvanizing involves immersing steel in molten zinc, creating a durable and thick zinc-iron alloy layer that offers superior protection against rust. Electroplating deposits a thin, uniform metal layer through an electrochemical process, providing aesthetic appeal and moderate corrosion resistance for lightweight or decorative components.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing is a corrosion protection method that involves immersing steel or iron in molten zinc, creating a durable, thick zinc coating that bonds metallurgically with the base metal. This process provides superior resistance to rust, making it ideal for construction materials exposed to outdoor environments and harsh weather conditions. Compared to electroplating, hot-dip galvanizing offers a longer-lasting, more robust coating that withstands abrasion and mechanical damage effectively.

Understanding the Electroplating Process

Electroplating involves depositing a thin metal coating onto a substrate by passing an electric current through a solution containing metal ions, enhancing corrosion resistance and aesthetic appeal. This process allows precise control over coating thickness and composition, making it ideal for protecting steel components used in construction and infrastructure. Unlike hot-dip galvanizing, electroplating can produce smoother, more uniform coatings critical for decorative or precision-engineered building materials.

Key Differences Between Hot-Dip Galvanizing and Electroplating

Hot-dip galvanizing involves immersing steel in molten zinc to create a thick, corrosion-resistant coating that offers superior durability and protection in harsh environments compared to electroplating. Electroplating deposits a thin layer of metal, such as zinc or nickel, through an electrolytic process, providing a smoother finish but less robust corrosion resistance. The key differences center on coating thickness, longevity, and resistance to environmental factors, with hot-dip galvanizing preferred for heavy-duty applications and electroplating favored for decorative or precision components.

Durability and Corrosion Resistance: A Comparative Analysis

Hot-dip galvanizing offers superior durability and corrosion resistance by coating steel with a thick layer of zinc that forms a robust, long-lasting barrier against rust and environmental damage. Electroplating provides a thinner, more uniform metal coating, often zinc or chrome, which offers moderate corrosion protection but is more prone to wear and damage over time. In environments with high moisture or industrial exposure, hot-dip galvanizing significantly extends the lifespan of steel components compared to electroplating.

Applications in the Building Materials Industry

Hot-dip galvanizing provides durable corrosion resistance for structural steel components used in bridges, roofing, and outdoor frameworks, making it ideal for heavy-duty building applications. Electroplating offers precise, thin protective coatings on metal fixtures and hardware, such as door handles and decorative elements, enhancing aesthetic appeal and corrosion protection. Both methods extend the lifespan of building materials but are chosen based on the required thickness, exposure conditions, and aesthetic requirements.

Environmental Impact and Sustainability Considerations

Hot-dip galvanizing provides superior corrosion resistance with a longer lifespan, reducing the frequency of recoating and waste generation compared to electroplating, which often involves toxic chemicals like cyanide and heavy metals posing significant environmental hazards. The hot-dip galvanizing process recycles zinc efficiently, promoting circular economy principles, whereas electroplating wastewater requires extensive treatment to mitigate pollution risks. Sustainability considerations favor hot-dip galvanizing due to lower energy consumption, reduced hazardous waste, and enhanced durability in building materials.

Cost Comparison: Hot-Dip Galvanizing vs Electroplating

Hot-dip galvanizing generally offers a lower overall cost compared to electroplating due to its thicker zinc coating, which provides longer-lasting corrosion resistance and reduces maintenance expenses. Electroplating initially appears cheaper due to lower material usage but may incur higher long-term costs from frequent recoating and shorter lifespan in harsh environments. Project-specific factors such as part size, complexity, and required durability significantly impact the cost-effectiveness between hot-dip galvanizing and electroplating methods.

Maintenance and Lifespan of Treated Materials

Hot-dip galvanizing provides superior corrosion resistance by forming a thick, durable zinc coating that withstands harsh environmental conditions, significantly extending the lifespan of steel structures with minimal maintenance. Electroplated coatings tend to be thinner and more prone to wear and corrosion, requiring more frequent inspections and touch-ups to maintain protection. The robust zinc-iron alloy layer developed during hot-dip galvanizing offers long-term durability, making it ideal for outdoor and industrial applications where extended maintenance intervals are crucial.

Choosing the Right Coating Method for Your Project

Hot-dip galvanizing provides a thicker, more durable zinc coating ideal for outdoor structures requiring long-term corrosion resistance, while electroplating offers a thinner, more precise layer suited for decorative or indoor applications. Project requirements such as environmental exposure, desired lifespan, and budget influence the choice, with galvanizing favored for heavy-duty protection and electroplating preferred for aesthetic finishes. Understanding the distinct advantages of each method ensures optimal performance and cost-effectiveness in construction and manufacturing projects.

Hot-dip Galvanizing vs Electroplating Infographic

productdif.com

productdif.com