Structural Insulated Panels (SIPs) offer superior thermal insulation and faster installation compared to Insulated Concrete Forms (ICFs), making them ideal for energy-efficient, quick-build projects. ICFs provide exceptional strength, durability, and soundproofing benefits due to their solid concrete core, which is preferable for disaster-resistant construction. Choosing between SIPs and ICFs depends on project priorities such as speed, insulation performance, and structural resilience.

Table of Comparison

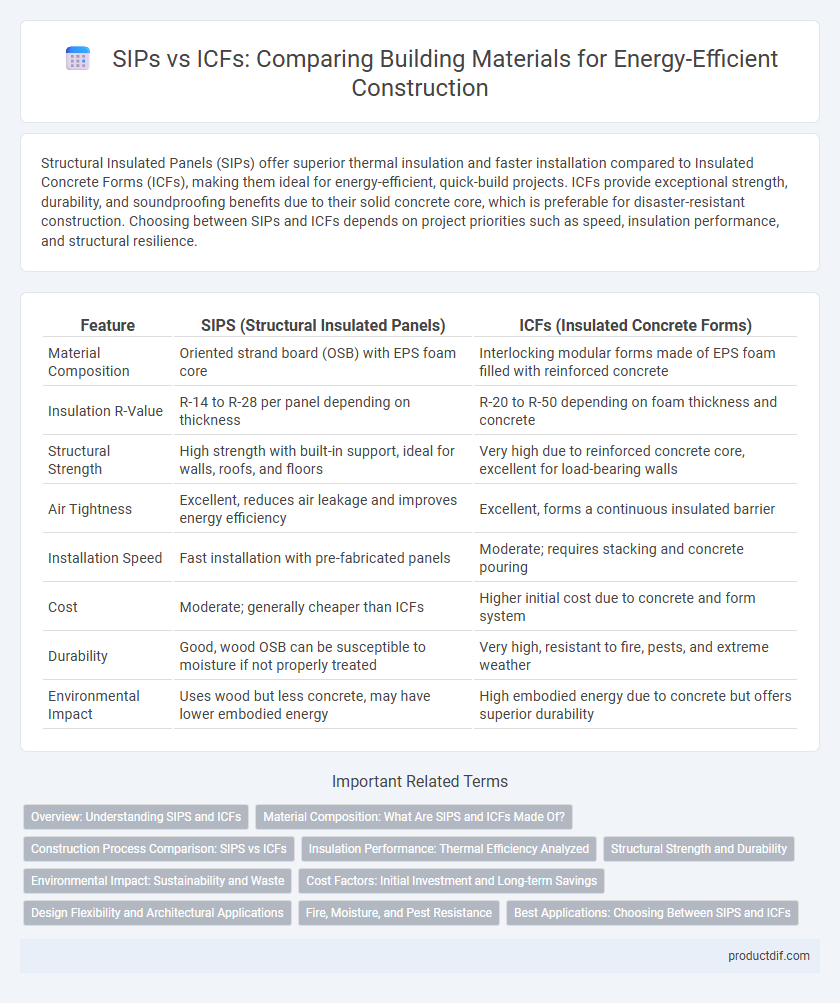

| Feature | SIPS (Structural Insulated Panels) | ICFs (Insulated Concrete Forms) |

|---|---|---|

| Material Composition | Oriented strand board (OSB) with EPS foam core | Interlocking modular forms made of EPS foam filled with reinforced concrete |

| Insulation R-Value | R-14 to R-28 per panel depending on thickness | R-20 to R-50 depending on foam thickness and concrete |

| Structural Strength | High strength with built-in support, ideal for walls, roofs, and floors | Very high due to reinforced concrete core, excellent for load-bearing walls |

| Air Tightness | Excellent, reduces air leakage and improves energy efficiency | Excellent, forms a continuous insulated barrier |

| Installation Speed | Fast installation with pre-fabricated panels | Moderate; requires stacking and concrete pouring |

| Cost | Moderate; generally cheaper than ICFs | Higher initial cost due to concrete and form system |

| Durability | Good, wood OSB can be susceptible to moisture if not properly treated | Very high, resistant to fire, pests, and extreme weather |

| Environmental Impact | Uses wood but less concrete, may have lower embodied energy | High embodied energy due to concrete but offers superior durability |

Overview: Understanding SIPS and ICFs

Structural Insulated Panels (SIPs) are prefabricated building components consisting of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB), offering excellent thermal performance and rapid installation. Insulated Concrete Forms (ICFs) combine rigid foam insulation with reinforced concrete, creating a durable, energy-efficient wall system known for superior strength and soundproofing. Both systems provide high energy efficiency and contribute to sustainable construction but differ in application, structural properties, and moisture resistance.

Material Composition: What Are SIPS and ICFs Made Of?

Structural Insulated Panels (SIPs) consist of an insulating foam core, typically expanded polystyrene (EPS) or polyurethane, sandwiched between two oriented strand board (OSB) facings. Insulated Concrete Forms (ICFs) are made from rigid foam blocks or panels, usually expanded polystyrene (EPS), which serve as permanent forms for pouring reinforced concrete. SIPs provide continuous insulation and structural support through their composite layers, while ICFs combine foam insulation with the strength and durability of poured concrete.

Construction Process Comparison: SIPS vs ICFs

Structural Insulated Panels (SIPS) offer a faster construction process due to their prefabricated nature, enabling quick on-site assembly and reducing labor costs. Insulated Concrete Forms (ICFs) require more time for installation since they involve stacking foam blocks and pouring concrete, which necessitates curing periods that extend the construction timeline. SIPS streamline project scheduling with minimal on-site modifications, while ICFs provide superior structural strength but demand longer build times and more skilled labor.

Insulation Performance: Thermal Efficiency Analyzed

Structural Insulated Panels (SIPs) provide superior thermal efficiency due to their continuous insulation layer that reduces thermal bridging, achieving R-values typically between R-14 and R-28 per 2-inch panel. Insulated Concrete Forms (ICFs) offer excellent thermal mass combined with continuous insulation, resulting in effective energy retention and R-values ranging from R-20 to R-50 depending on block thickness and foam type. Both building materials enhance insulation performance significantly, but SIPs excel in air-tightness while ICFs leverage thermal mass for consistent indoor temperature regulation.

Structural Strength and Durability

Structural Insulated Panels (SIPs) offer exceptional rigidity and load-bearing capacity due to their engineered wood cores and continuous insulation, making them highly resistant to bending and shear forces. Insulated Concrete Forms (ICFs) provide superior durability with reinforced concrete cores that resist moisture, fire, and pests, contributing to long-lasting structural integrity. Both materials deliver robust strength, but ICFs excel in impact resistance and longevity, while SIPs prioritize efficiency and stiffness in framed assemblies.

Environmental Impact: Sustainability and Waste

Structural Insulated Panels (SIPS) offer significant environmental benefits through reduced construction waste due to their prefabricated nature and precise manufacturing process. Insulated Concrete Forms (ICFs) contribute to sustainability by providing excellent thermal insulation and durability, which reduces energy consumption over a building's lifecycle. Both materials promote eco-friendly building practices by minimizing resource use and enhancing energy efficiency, but SIPS typically generate less onsite waste compared to ICFs.

Cost Factors: Initial Investment and Long-term Savings

Structural Insulated Panels (SIPs) generally require a higher initial investment compared to Insulated Concrete Forms (ICFs) due to their manufacturing and transportation costs. ICFs offer long-term savings through enhanced thermal mass and durability, reducing energy bills and maintenance expenses over time. Evaluating cost factors involves balancing SIPs' quicker installation times against ICFs' superior energy efficiency and structural longevity.

Design Flexibility and Architectural Applications

Structural Insulated Panels (SIPS) offer superior design flexibility with their lightweight, prefabricated nature, allowing for complex shapes and rapid installation in a variety of architectural applications such as residential and commercial buildings. Insulated Concrete Forms (ICFs) provide robust thermal insulation and structural strength but are more suited to straightforward designs due to their bulky, rigid formwork. Architects favor SIPS for intricate rooflines and curved walls, while ICFs are preferred in energy-efficient, load-bearing walls for foundations and basements.

Fire, Moisture, and Pest Resistance

Structural Insulated Panels (SIPs) offer superior fire resistance due to their fire-retardant facings and rigid foam core, which slows flame spread compared to traditional framing. Insulated Concrete Forms (ICFs) provide exceptional moisture resistance through their solid concrete core that prevents water infiltration, reducing mold risk. Both systems offer strong pest resistance, with ICFs deterring insects by eliminating wood components and SIPs incorporating treated materials to inhibit termite and rodent damage.

Best Applications: Choosing Between SIPS and ICFs

Structural Insulated Panels (SIPs) are ideal for residential and light commercial buildings requiring fast construction and high energy efficiency, particularly in climates with moderate weather variations. Insulated Concrete Forms (ICFs) excel in projects demanding superior durability, soundproofing, and resistance to extreme weather events, making them suitable for foundations, basements, and buildings in hurricane or seismic zones. Selecting between SIPs and ICFs depends on project priorities like construction speed, insulation performance, structural strength, and climate resilience.

SIPS vs ICFs Infographic

productdif.com

productdif.com