Post-tensioning involves casting concrete first and then tensioning the steel tendons, which allows for longer spans and reduced structural thickness. Pre-tensioning stretches the steel tendons before concrete is poured, resulting in enhanced bond strength for precast elements. Both methods improve concrete performance, but post-tensioning offers greater flexibility in design for in-situ construction.

Table of Comparison

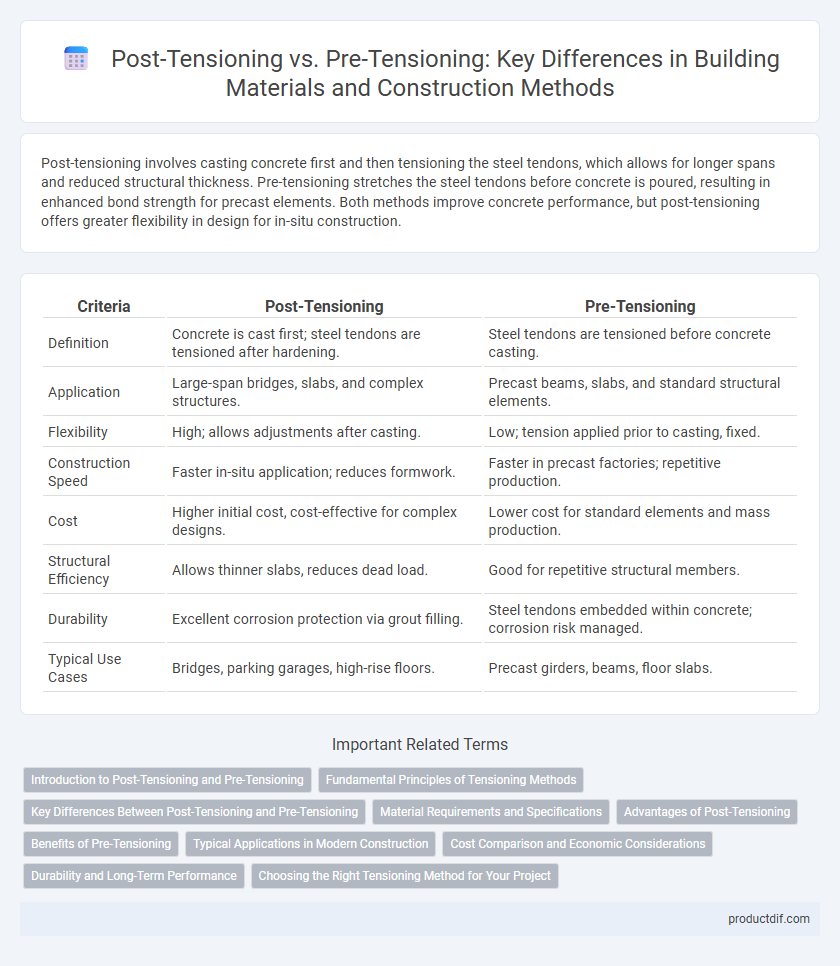

| Criteria | Post-Tensioning | Pre-Tensioning |

|---|---|---|

| Definition | Concrete is cast first; steel tendons are tensioned after hardening. | Steel tendons are tensioned before concrete casting. |

| Application | Large-span bridges, slabs, and complex structures. | Precast beams, slabs, and standard structural elements. |

| Flexibility | High; allows adjustments after casting. | Low; tension applied prior to casting, fixed. |

| Construction Speed | Faster in-situ application; reduces formwork. | Faster in precast factories; repetitive production. |

| Cost | Higher initial cost, cost-effective for complex designs. | Lower cost for standard elements and mass production. |

| Structural Efficiency | Allows thinner slabs, reduces dead load. | Good for repetitive structural members. |

| Durability | Excellent corrosion protection via grout filling. | Steel tendons embedded within concrete; corrosion risk managed. |

| Typical Use Cases | Bridges, parking garages, high-rise floors. | Precast girders, beams, floor slabs. |

Introduction to Post-Tensioning and Pre-Tensioning

Post-tensioning involves casting concrete around ducts containing steel tendons, which are tensioned after the concrete hardens, enhancing structural strength and reducing material usage. Pre-tensioning features steel tendons stretched before concrete placement, transferring tensile forces to the concrete once it cures, commonly used in precast elements. Both methods improve load-bearing capacity and control cracking but differ in application timing and construction processes.

Fundamental Principles of Tensioning Methods

Post-tensioning involves casting concrete with ducts through which tendons are tensioned after the concrete hardens, creating compressive stress to counteract tensile forces. Pre-tensioning applies tension to steel tendons before concrete placement, transferring the stress to the concrete once it cures and the tendons are released. Both methods enhance structural performance by controlling tensile stresses in concrete elements, but differ in tendon placement, timing, and application suited to specific construction scenarios.

Key Differences Between Post-Tensioning and Pre-Tensioning

Post-tensioning involves casting concrete first and then tensioning the steel tendons after the concrete has gained strength, while pre-tensioning requires tensioning the steel tendons before the concrete is cast. Post-tensioned systems offer greater flexibility in terms of shape and on-site adaptability, whereas pre-tensioned elements are typically manufactured in factory conditions, ensuring higher quality control. Key differences include tendon placement timing, construction process, and structural application suitability, with post-tensioning often used for longer spans and complex geometries.

Material Requirements and Specifications

Post-tensioning requires high-strength steel tendons with superior ductility to allow tensioning after concrete placement, whereas pre-tensioning uses prestressed steel wires or strands stressed before concrete casting. Both methods demand concrete with high compressive strength, but post-tensioning specifically needs concrete with adequate toughness to withstand in-service stresses without cracking. Material specifications emphasize corrosion-resistant steel tendons and carefully controlled concrete mix designs to optimize durability and load-bearing performance in structural applications.

Advantages of Post-Tensioning

Post-tensioning offers enhanced structural strength and flexibility by applying tension after concrete has cured, allowing for longer spans and thinner slabs compared to pre-tensioning. It reduces cracking and deflection, improving durability and service life in building materials. This method also allows for on-site tensioning adjustments, providing greater design versatility for complex construction projects.

Benefits of Pre-Tensioning

Pre-tensioning enhances structural efficiency by applying tensile forces to steel tendons before concrete placement, resulting in higher load-bearing capacity and reduced cracking. This method improves durability and accelerates construction timelines due to its factory-controlled environment, offering consistent quality and minimized onsite labor. Pre-tensioning is especially beneficial for precast concrete elements, providing better dimensional stability and resistance to shrinkage and temperature variations.

Typical Applications in Modern Construction

Post-tensioning is widely used in large-span structures such as bridges, parking garages, and high-rise buildings, where precise control of concrete tension enhances load-bearing capacity and reduces material usage. Pre-tensioning is typically applied in the manufacturing of precast concrete elements like beams, slabs, and railway sleepers, providing uniform tensile strength and rapid production in controlled factory environments. Both techniques improve structural performance but are selected based on design requirements, site conditions, and construction workflow efficiencies.

Cost Comparison and Economic Considerations

Post-tensioning generally offers lower labor costs and reduced material usage compared to pre-tensioning due to its on-site tensioning process, which enhances structural efficiency and minimizes steel reinforcement requirements. Pre-tensioning tends to incur higher initial costs because of the need for specialized casting beds and centralized fabrication facilities, limiting project flexibility and transportation options. Economic considerations favor post-tensioning for complex or large-scale projects where long spans and reduced dead loads translate into overall cost savings despite higher tensioning equipment investment.

Durability and Long-Term Performance

Post-tensioning enhances durability by reducing cracks and allowing for thinner slabs with higher load capacity, leading to improved long-term structural performance. Pre-tensioning offers strong bond strength between concrete and steel tendons, resulting in consistent quality and resistance to fatigue over time. Both methods prolong service life, but post-tensioning provides greater flexibility in design and load adjustments, which benefits long-term maintenance.

Choosing the Right Tensioning Method for Your Project

Post-tensioning offers greater flexibility for complex architectural designs and long-span structures by applying tension after concrete hardening, enhancing load capacity and crack control. Pre-tensioning provides efficient mass production benefits with high early strength, ideal for precast concrete elements like beams and slabs. Selecting the right tensioning method depends on project scale, structural requirements, and construction timelines to optimize performance and cost-effectiveness.

Post-tensioning vs Pre-tensioning Infographic

productdif.com

productdif.com