XPS (extruded polystyrene) offers higher compressive strength and superior moisture resistance compared to EPS (expanded polystyrene), making it ideal for insulation in high-wear or damp environments. EPS is more cost-effective and environmentally friendly due to its recyclability and lower embodied energy, suitable for less demanding insulation applications. Choosing between XPS and EPS depends on balancing performance requirements with budget and sustainability goals in building projects.

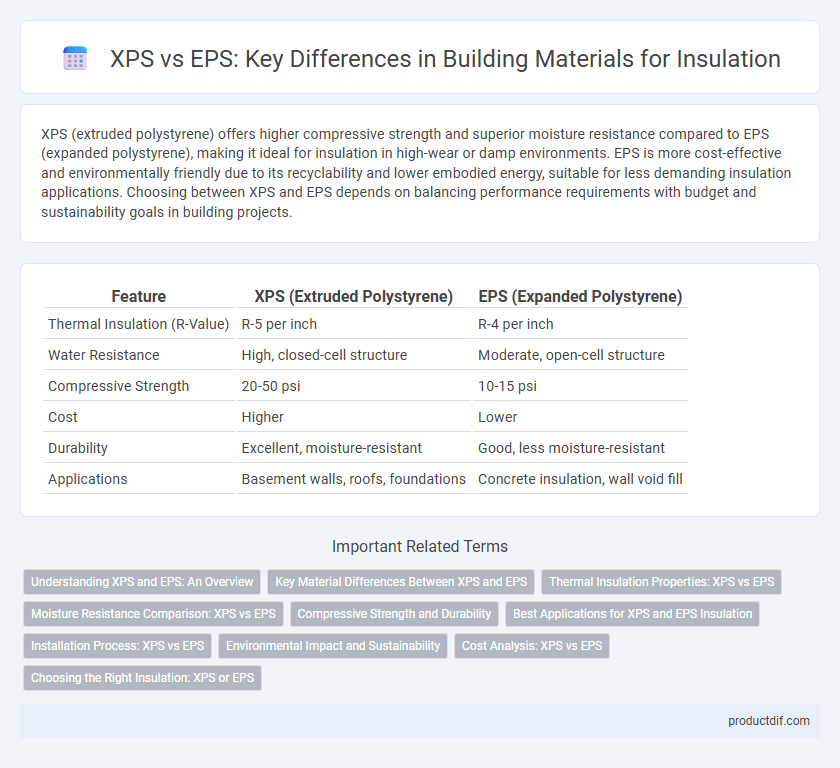

Table of Comparison

| Feature | XPS (Extruded Polystyrene) | EPS (Expanded Polystyrene) |

|---|---|---|

| Thermal Insulation (R-Value) | R-5 per inch | R-4 per inch |

| Water Resistance | High, closed-cell structure | Moderate, open-cell structure |

| Compressive Strength | 20-50 psi | 10-15 psi |

| Cost | Higher | Lower |

| Durability | Excellent, moisture-resistant | Good, less moisture-resistant |

| Applications | Basement walls, roofs, foundations | Concrete insulation, wall void fill |

Understanding XPS and EPS: An Overview

Extruded Polystyrene (XPS) offers higher compressive strength and better moisture resistance compared to Expanded Polystyrene (EPS), making it ideal for use in below-grade insulation and roofing applications. EPS consists of molded beads and provides good thermal insulation with greater vapor permeability, often preferred for wall insulation where breathability is important. Both XPS and EPS are lightweight, cost-effective rigid foam boards widely used in construction for energy efficiency and thermal performance.

Key Material Differences Between XPS and EPS

XPS (Extruded Polystyrene) features a closed-cell structure, providing higher compressive strength and superior moisture resistance compared to EPS (Expanded Polystyrene), which has an open-cell design. The density of XPS typically ranges from 1.5 to 2.0 pounds per cubic foot, while EPS varies between 0.9 to 1.5 pounds per cubic foot, influencing insulation performance and durability. Thermal conductivity for XPS is generally lower (around 0.029 W/m*K) than EPS (approximately 0.035 W/m*K), making XPS more effective for long-term thermal insulation in construction.

Thermal Insulation Properties: XPS vs EPS

XPS (Extruded Polystyrene) offers a higher R-value per inch, typically around 5, compared to EPS (Expanded Polystyrene), which ranges from 3.6 to 4.2, making XPS more effective for thermal insulation. XPS features a closed-cell structure that minimizes water absorption and maintains insulation performance in moist conditions, whereas EPS has an open-cell structure, which can absorb more moisture and reduce thermal resistance over time. The superior compressive strength and moisture resistance of XPS make it ideal for applications requiring durable thermal insulation in demanding environments.

Moisture Resistance Comparison: XPS vs EPS

Extruded Polystyrene (XPS) offers superior moisture resistance compared to Expanded Polystyrene (EPS) due to its closed-cell structure, which minimizes water absorption and enhances durability in damp environments. EPS, with its open-cell configuration, tends to absorb more water, leading to reduced thermal performance and potential degradation over time. Selecting XPS is crucial for applications requiring high resistance to moisture infiltration, such as below-grade insulation and roofing systems.

Compressive Strength and Durability

Extruded Polystyrene (XPS) offers higher compressive strength, typically ranging from 20 to 45 psi, compared to Expanded Polystyrene (EPS), which usually ranges from 10 to 25 psi. XPS demonstrates superior durability due to its closed-cell structure, making it more resistant to moisture absorption and long-term compression. EPS, while cost-effective, may degrade faster under sustained loads and exposure to environmental factors, impacting its longevity in building insulation applications.

Best Applications for XPS and EPS Insulation

XPS insulation excels in applications requiring high compressive strength and moisture resistance, making it ideal for below-grade foundations, roofing, and areas exposed to water. EPS insulation suits projects prioritizing cost-effectiveness and thermal performance in dry environments, commonly used in wall cavities, attic insulation, and insulated concrete forms. Both materials offer distinct advantages based on environmental conditions and structural requirements.

Installation Process: XPS vs EPS

XPS (extruded polystyrene) offers a streamlined installation process due to its rigid, dense structure, making it easier to cut and fit seamlessly around complex shapes and tight spaces. EPS (expanded polystyrene) requires more careful handling during installation because its bead-like composition can crumble, leading to potential gaps and less consistent insulation performance. Both materials benefit from adhesive or mechanical fastening, but XPS generally reduces installation time and labor costs due to its superior durability and moisture resistance.

Environmental Impact and Sustainability

XPS (Extruded Polystyrene) insulation typically has a higher environmental impact due to its production process, which involves hydrofluorocarbons (HFCs) with a high global warming potential, whereas EPS (Expanded Polystyrene) uses pentane as a blowing agent, resulting in lower greenhouse gas emissions. EPS offers greater sustainability through better recyclability and lower embodied energy compared to XPS, making it a preferable choice for eco-conscious building projects. Furthermore, EPS's closed-cell structure provides effective insulation while minimizing environmental harm throughout its lifecycle.

Cost Analysis: XPS vs EPS

Extruded Polystyrene (XPS) generally incurs higher initial costs than Expanded Polystyrene (EPS) due to its denser structure and superior insulating properties. EPS offers a cost-effective option with a lower price per cubic foot but may require thicker layers to achieve equivalent thermal resistance compared to XPS. When evaluating long-term value, XPS often reduces energy expenses in climates with extreme temperature variations, potentially offsetting its upfront premium through enhanced durability and moisture resistance.

Choosing the Right Insulation: XPS or EPS

Extruded Polystyrene (XPS) offers higher compressive strength and better moisture resistance, making it ideal for below-grade foundations and high-load applications. Expanded Polystyrene (EPS) provides cost-effective insulation with good thermal performance and is suitable for interior walls, roof insulation, and wall cavities. Selecting the right insulation depends on project requirements such as moisture exposure, load-bearing needs, and budget constraints.

XPS vs EPS Infographic

productdif.com

productdif.com