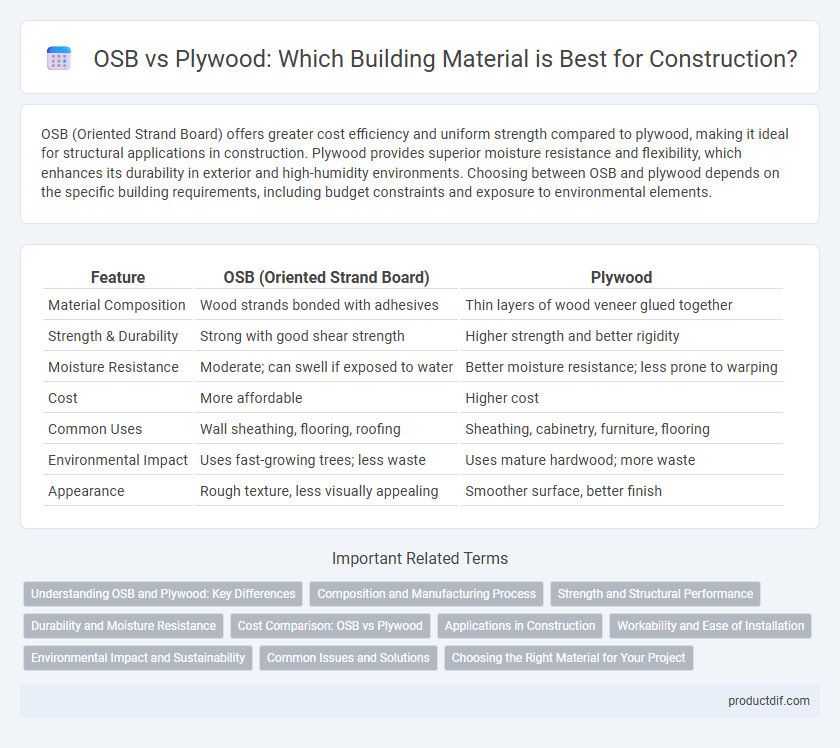

OSB (Oriented Strand Board) offers greater cost efficiency and uniform strength compared to plywood, making it ideal for structural applications in construction. Plywood provides superior moisture resistance and flexibility, which enhances its durability in exterior and high-humidity environments. Choosing between OSB and plywood depends on the specific building requirements, including budget constraints and exposure to environmental elements.

Table of Comparison

| Feature | OSB (Oriented Strand Board) | Plywood |

|---|---|---|

| Material Composition | Wood strands bonded with adhesives | Thin layers of wood veneer glued together |

| Strength & Durability | Strong with good shear strength | Higher strength and better rigidity |

| Moisture Resistance | Moderate; can swell if exposed to water | Better moisture resistance; less prone to warping |

| Cost | More affordable | Higher cost |

| Common Uses | Wall sheathing, flooring, roofing | Sheathing, cabinetry, furniture, flooring |

| Environmental Impact | Uses fast-growing trees; less waste | Uses mature hardwood; more waste |

| Appearance | Rough texture, less visually appealing | Smoother surface, better finish |

Understanding OSB and Plywood: Key Differences

Oriented Strand Board (OSB) is manufactured from compressed wood strands and adhesives, offering consistent strength and cost-efficiency, while plywood is made by layering thin wood veneers in alternating grain directions for enhanced durability and moisture resistance. OSB typically provides better shear strength, making it ideal for structural applications, whereas plywood is preferred for projects requiring higher resistance to water and impact. Both materials vary in price and performance based on factors such as thickness, grade, and intended use in construction tasks.

Composition and Manufacturing Process

Oriented Strand Board (OSB) is made from compressed layers of wood strands arranged in specific orientations and bonded with resin adhesives, creating a dense, uniform panel ideal for structural applications. Plywood consists of thin layers of wood veneers glued together with the grain of adjacent layers rotated, enhancing strength and resistance to warping. The OSB manufacturing process involves shredding logs into strands followed by layering and pressing, while plywood production requires slicing logs into veneers before gluing and pressing them under heat and pressure.

Strength and Structural Performance

Oriented Strand Board (OSB) offers equivalent shear strength and stiffness compared to plywood, making it suitable for load-bearing applications such as roof decking and wall sheathing. Plywood typically exhibits higher resistance to moisture-induced warping and delamination due to its cross-laminated veneer composition, contributing to longer-term structural durability. Both materials meet industry standards like APA-rated performance, but OSB's uniform density and cost-effectiveness make it a preferred choice in large-scale construction projects requiring consistent strength and structural reliability.

Durability and Moisture Resistance

OSB (Oriented Strand Board) and plywood both offer strong structural support, but plywood generally demonstrates superior durability and moisture resistance due to its cross-laminated veneer layers that better resist warping and delamination. OSB's engineered composition can absorb moisture more readily, leading to potential swelling and reduced structural integrity over time when exposed to high humidity or water. Moisture-resistant treated plywood outperforms standard OSB in longevity for applications in damp environments or exterior use.

Cost Comparison: OSB vs Plywood

Oriented Strand Board (OSB) generally costs 20-30% less than plywood, making it a budget-friendly option for construction projects. Prices for OSB typically range from $10 to $15 per sheet, while plywood costs between $15 and $25 per sheet depending on grade and thickness. The lower price of OSB results from its manufacturing process, which uses smaller wood strands and adhesives, maximizing material efficiency and reducing waste.

Applications in Construction

OSB (Oriented Strand Board) is widely used for wall sheathing, roof decking, and subflooring due to its strength, affordability, and moisture resistance. Plywood remains preferred for applications requiring superior durability and water resistance, such as exterior walls, flooring, and roofing underlayment in high-load or wet conditions. Both materials support load-bearing structures, but choice depends on project requirements for cost, exposure to elements, and structural demands.

Workability and Ease of Installation

Oriented Strand Board (OSB) offers superior workability due to its uniform density and consistent panel size, making it easier to cut and fasten during construction. Plywood, with its layered veneer structure, provides enhanced flexibility and resistance to splitting, facilitating easier handling and installation in curved or irregular surfaces. Both materials feature pre-drilled holes and standard thickness options, allowing for straightforward attachment with nails or screws in various building applications.

Environmental Impact and Sustainability

Oriented Strand Board (OSB) typically has a lower environmental impact compared to plywood because it uses smaller, fast-growing trees and maximizes wood fiber utilization, reducing waste. Plywood production often relies on larger, older trees, leading to greater deforestation concerns and higher energy consumption. OSB's formaldehyde-free adhesives and efficient manufacturing processes contribute to its higher sustainability rating in eco-friendly construction projects.

Common Issues and Solutions

OSB (Oriented Strand Board) commonly faces moisture-related swelling and edge deterioration, while plywood is prone to delamination and surface cracking under prolonged exposure to water. Applying water-resistant sealants and proper installation with moisture barriers effectively mitigates OSB swelling and edge damage. For plywood, using exterior-grade adhesive and maintaining protective coatings reduces the risk of delamination and structural weakening.

Choosing the Right Material for Your Project

OSB (Oriented Strand Board) offers superior shear strength and cost-effectiveness, making it ideal for structural applications like wall sheathing and roof decking. Plywood provides better moisture resistance and dimensional stability, suitable for projects exposed to humidity or requiring enhanced durability. Selecting between OSB and plywood depends on project requirements such as load-bearing capacity, exposure to elements, and budget constraints.

OSB vs Plywood Infographic

productdif.com

productdif.com