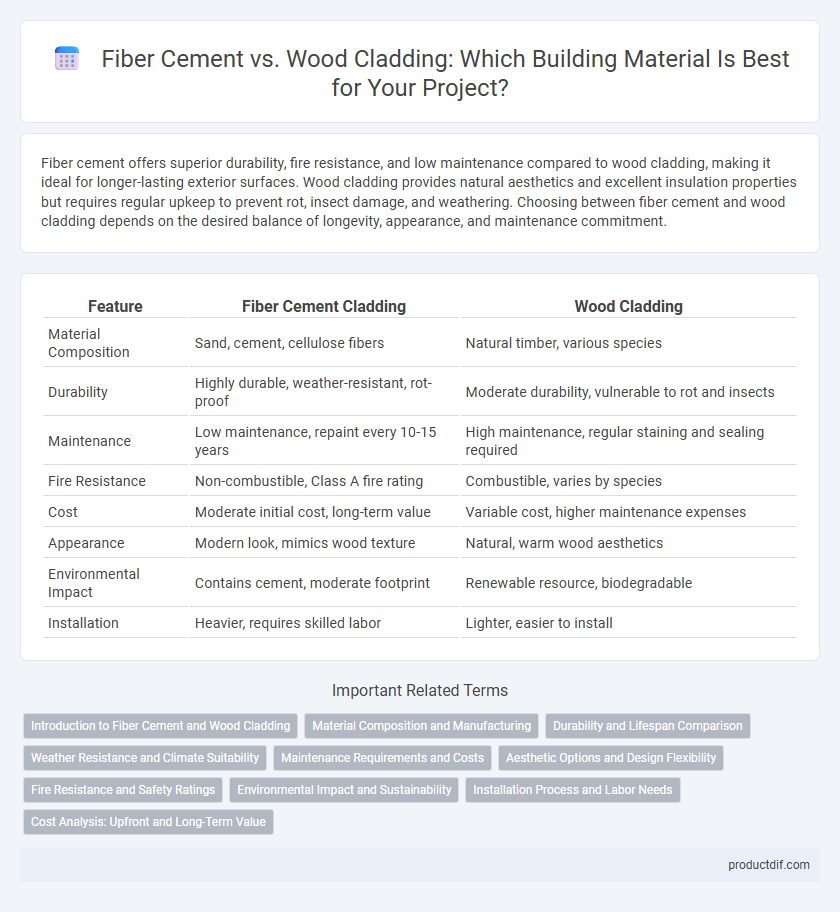

Fiber cement offers superior durability, fire resistance, and low maintenance compared to wood cladding, making it ideal for longer-lasting exterior surfaces. Wood cladding provides natural aesthetics and excellent insulation properties but requires regular upkeep to prevent rot, insect damage, and weathering. Choosing between fiber cement and wood cladding depends on the desired balance of longevity, appearance, and maintenance commitment.

Table of Comparison

| Feature | Fiber Cement Cladding | Wood Cladding |

|---|---|---|

| Material Composition | Sand, cement, cellulose fibers | Natural timber, various species |

| Durability | Highly durable, weather-resistant, rot-proof | Moderate durability, vulnerable to rot and insects |

| Maintenance | Low maintenance, repaint every 10-15 years | High maintenance, regular staining and sealing required |

| Fire Resistance | Non-combustible, Class A fire rating | Combustible, varies by species |

| Cost | Moderate initial cost, long-term value | Variable cost, higher maintenance expenses |

| Appearance | Modern look, mimics wood texture | Natural, warm wood aesthetics |

| Environmental Impact | Contains cement, moderate footprint | Renewable resource, biodegradable |

| Installation | Heavier, requires skilled labor | Lighter, easier to install |

Introduction to Fiber Cement and Wood Cladding

Fiber cement is a durable building material composed of cement, sand, and cellulose fibers, offering resistance to fire, moisture, and pests, making it ideal for exterior cladding. Wood cladding provides a natural aesthetic with excellent insulative properties but requires regular maintenance to prevent rot, insect damage, and weathering. Both materials serve distinct architectural purposes, with fiber cement favored for longevity and wood cladding prized for its organic appeal.

Material Composition and Manufacturing

Fiber cement cladding is composed of a mixture of cement, cellulose fibers, sand, and water, cured through a controlled autoclaving process for enhanced durability and resistance to moisture and fire. Wood cladding consists of natural timber, typically cedar, pine, or redwood, shaped and treated through kiln drying and chemical preservatives to improve longevity and prevent decay. The manufacturing of fiber cement involves precision mixing and molding techniques, while wood cladding relies on sustainable harvesting, milling, and surface finishing methods to maintain its aesthetic and structural integrity.

Durability and Lifespan Comparison

Fiber cement cladding offers superior durability compared to wood, resisting rot, termites, and fire while maintaining structural integrity in harsh weather conditions. Wood cladding, though aesthetically appealing, typically has a shorter lifespan due to vulnerability to moisture damage, insect infestations, and general wear. Fiber cement can last up to 50 years with minimal maintenance, whereas wood cladding often requires frequent upkeep and may last 20-30 years under similar conditions.

Weather Resistance and Climate Suitability

Fiber cement offers superior weather resistance compared to wood cladding, as it is impervious to moisture, rot, and insect damage, making it ideal for humid or coastal climates. Wood cladding, while aesthetically pleasing, requires regular maintenance and protective treatments to withstand harsh weather conditions and is better suited for temperate climates with moderate humidity. Choosing fiber cement ensures durability and minimal upkeep in extreme weather, whereas wood cladding provides natural insulation benefits but demands more care to prevent climate-induced deterioration.

Maintenance Requirements and Costs

Fiber cement cladding offers superior durability with minimal maintenance, typically requiring only occasional cleaning and repainting every 10-15 years, resulting in lower long-term costs. Wood cladding demands regular upkeep including annual sealing or staining and frequent inspections to prevent rot, insect damage, and warping, which significantly increase maintenance expenses over time. The initial installation cost of fiber cement is higher, but its longevity and reduced maintenance needs make it a more cost-effective choice compared to wood cladding.

Aesthetic Options and Design Flexibility

Fiber cement offers a wide range of textures and colors that mimic natural wood, stone, and stucco, providing versatile aesthetic options for modern and traditional designs. Wood cladding delivers authentic warmth and character with grain patterns and finishes that can be customized through staining or painting, allowing for timeless and rustic appeal. Both materials enable flexible design approaches, but fiber cement's durability expands creative possibilities in high-moisture or fire-prone environments, while wood excels in natural and organic architectural styles.

Fire Resistance and Safety Ratings

Fiber cement cladding offers superior fire resistance compared to wood cladding, as it is non-combustible and meets Class A fire safety ratings, making it ideal for buildings in high-risk fire areas. Wood cladding, while aesthetically pleasing, is combustible and typically requires fire-retardant treatments to improve safety but still falls short of fiber cement's inherent fire-resistant properties. Building codes often favor fiber cement for safer exterior cladding solutions due to its durability and compliance with stringent fire performance standards.

Environmental Impact and Sustainability

Fiber cement cladding offers superior environmental performance due to its durability, low maintenance, and resistance to pests and rot, reducing the need for frequent replacements and resource consumption. Wood cladding, while renewable and biodegradable, often involves deforestation and requires chemical treatments that can harm ecosystems. Choosing fiber cement can significantly lower a building's carbon footprint and promote sustainable construction by minimizing waste and conserving natural resources.

Installation Process and Labor Needs

Fiber cement cladding requires specialized tools and skilled labor for cutting and installation, often involving heavier materials that increase labor intensity. Wood cladding offers easier handling and simpler installation, with faster cutting and nailing processes, reducing overall labor time and costs. Despite higher initial labor needs, fiber cement provides long-term durability benefits that can offset installation challenges.

Cost Analysis: Upfront and Long-Term Value

Fiber cement cladding typically incurs higher upfront costs than wood cladding, averaging $5 to $11 per square foot compared to wood's $3 to $7, but offers superior durability and lower maintenance expenses over time. Wood cladding requires periodic sealing, painting, and potential repairs, increasing long-term maintenance costs that can exceed initial savings within 5 to 10 years. Fiber cement's resistance to rot, pests, and fire contributes to greater longevity and enhances overall value despite the initial investment.

Fiber Cement vs Wood Cladding Infographic

productdif.com

productdif.com