Insulated Concrete Forms (ICFs) offer superior thermal insulation and energy efficiency compared to Concrete Masonry Units (CMUs), reducing heating and cooling costs in building projects. ICFs provide enhanced structural strength and airtightness, making them a preferred choice for durable and sustainable construction. Concrete Masonry Units remain cost-effective and easy to install but lack the insulating properties and continuous thermal barrier that ICFs deliver.

Table of Comparison

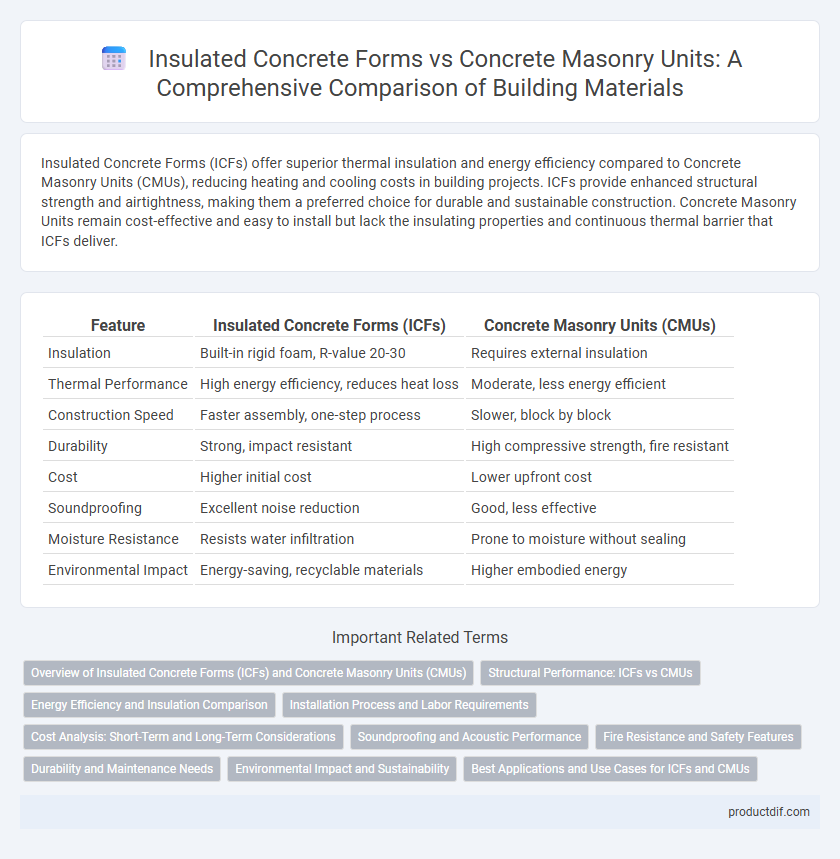

| Feature | Insulated Concrete Forms (ICFs) | Concrete Masonry Units (CMUs) |

|---|---|---|

| Insulation | Built-in rigid foam, R-value 20-30 | Requires external insulation |

| Thermal Performance | High energy efficiency, reduces heat loss | Moderate, less energy efficient |

| Construction Speed | Faster assembly, one-step process | Slower, block by block |

| Durability | Strong, impact resistant | High compressive strength, fire resistant |

| Cost | Higher initial cost | Lower upfront cost |

| Soundproofing | Excellent noise reduction | Good, less effective |

| Moisture Resistance | Resists water infiltration | Prone to moisture without sealing |

| Environmental Impact | Energy-saving, recyclable materials | Higher embodied energy |

Overview of Insulated Concrete Forms (ICFs) and Concrete Masonry Units (CMUs)

Insulated Concrete Forms (ICFs) are engineered building blocks made of rigid insulation panels filled with reinforced concrete, offering superior thermal efficiency and soundproofing. Concrete Masonry Units (CMUs), commonly known as concrete blocks, consist of solid or hollow concrete and provide durability and fire resistance but less insulation compared to ICFs. ICFs integrate structural strength and insulation in a single system, while CMUs often require additional insulation for energy performance.

Structural Performance: ICFs vs CMUs

Insulated Concrete Forms (ICFs) provide superior structural performance compared to Concrete Masonry Units (CMUs) due to their continuous concrete core reinforced with steel, offering enhanced load-bearing capacity and resistance to lateral forces like wind and seismic activity. ICFs also deliver improved thermal insulation and soundproofing within the same structural envelope, resulting in energy-efficient and durable building envelopes. In contrast, CMUs rely on grout-filled cells and mortar joints, which can create weaker points impacting overall structural integrity under heavy loads or dynamic stress conditions.

Energy Efficiency and Insulation Comparison

Insulated Concrete Forms (ICFs) provide superior energy efficiency compared to Concrete Masonry Units (CMUs) due to their continuous insulation and airtight construction, which significantly reduces thermal bridging and heat loss. ICFs typically achieve R-values between R-20 and R-30, whereas CMUs have much lower R-values, often requiring additional insulation to meet energy standards. The integrated foam insulation within ICFs enhances thermal performance, leading to lower energy consumption and improved indoor comfort relative to traditional CMU walls.

Installation Process and Labor Requirements

Insulated Concrete Forms (ICFs) streamline the installation process with lightweight, interlocking blocks that reduce labor time by up to 30% compared to traditional Concrete Masonry Units (CMUs), which require skilled masons and mortar application. ICFs integrate insulation and formwork in one step, minimizing the need for additional materials and specialized labor. CMUs demand precise alignment and curing time, resulting in longer project schedules and higher labor costs.

Cost Analysis: Short-Term and Long-Term Considerations

Insulated Concrete Forms (ICFs) typically have higher upfront material and labor costs compared to Concrete Masonry Units (CMUs), but their superior energy efficiency reduces long-term utility expenses significantly. CMUs offer lower initial expenditure and faster construction times, making them cost-effective for short-term budgets but may incur higher heating and cooling costs over time. Evaluating lifecycle costs reveals that ICFs provide better return on investment through energy savings, durability, and reduced maintenance costs, outweighing the initial price differential.

Soundproofing and Acoustic Performance

Insulated Concrete Forms (ICFs) provide superior soundproofing compared to Concrete Masonry Units (CMUs) due to their continuous insulation and airtight construction, reducing airborne noise effectively. ICFs typically achieve a Sound Transmission Class (STC) rating of 50-60, significantly higher than most CMU walls, which generally range from 45-50. The foam insulation within ICFs also dampens vibrations, enhancing acoustic performance in residential and commercial buildings.

Fire Resistance and Safety Features

Insulated Concrete Forms (ICFs) offer superior fire resistance due to their combination of reinforced concrete and expanded polystyrene insulation, which can withstand temperatures exceeding 2,000degF without structural failure. Concrete Masonry Units (CMUs) provide inherent fire resistance because of their dense, non-combustible composition, but often lack the thermal insulating properties that enhance overall safety in fire scenarios. Fire safety features in ICFs include continuous insulation that prevents fire spread, while CMUs rely on thickness and mass to resist heat penetration, making ICFs more effective in comprehensive fire protection systems.

Durability and Maintenance Needs

Insulated Concrete Forms (ICFs) offer superior durability due to their integrated insulation and concrete core, providing resistance to moisture, pests, and extreme weather conditions. Concrete Masonry Units (CMUs) require regular maintenance such as sealing and repointing to prevent water infiltration and cracking over time. The low-maintenance nature of ICFs reduces long-term repair costs compared to the more upkeep-intensive CMUs.

Environmental Impact and Sustainability

Insulated Concrete Forms (ICFs) offer superior thermal insulation, reducing energy consumption and greenhouse gas emissions compared to Concrete Masonry Units (CMUs), which have higher embodied carbon due to dense, less energy-efficient materials. ICFs contribute to sustainable construction through better air sealing and moisture resistance, enhancing indoor air quality and lowering long-term operational carbon footprints. While CMUs are recyclable, their production involves higher energy use, making ICFs a more environmentally responsible choice for green building projects focused on reducing lifecycle environmental impact.

Best Applications and Use Cases for ICFs and CMUs

Insulated Concrete Forms (ICFs) are best suited for energy-efficient residential construction, offering superior thermal insulation and airtightness that reduces heating and cooling costs, ideal for climate zones with extreme temperature variations. Concrete Masonry Units (CMUs) excel in commercial and industrial buildings requiring high structural strength, fire resistance, and cost-effective, modular construction, particularly in load-bearing walls and retaining structures. ICFs provide enhanced soundproofing and moisture resistance, making them preferred for basements and exterior walls, while CMUs are often chosen for foundations and interior partitions due to their durability and ease of installation.

Insulated Concrete Forms vs Concrete Masonry Units Infographic

productdif.com

productdif.com