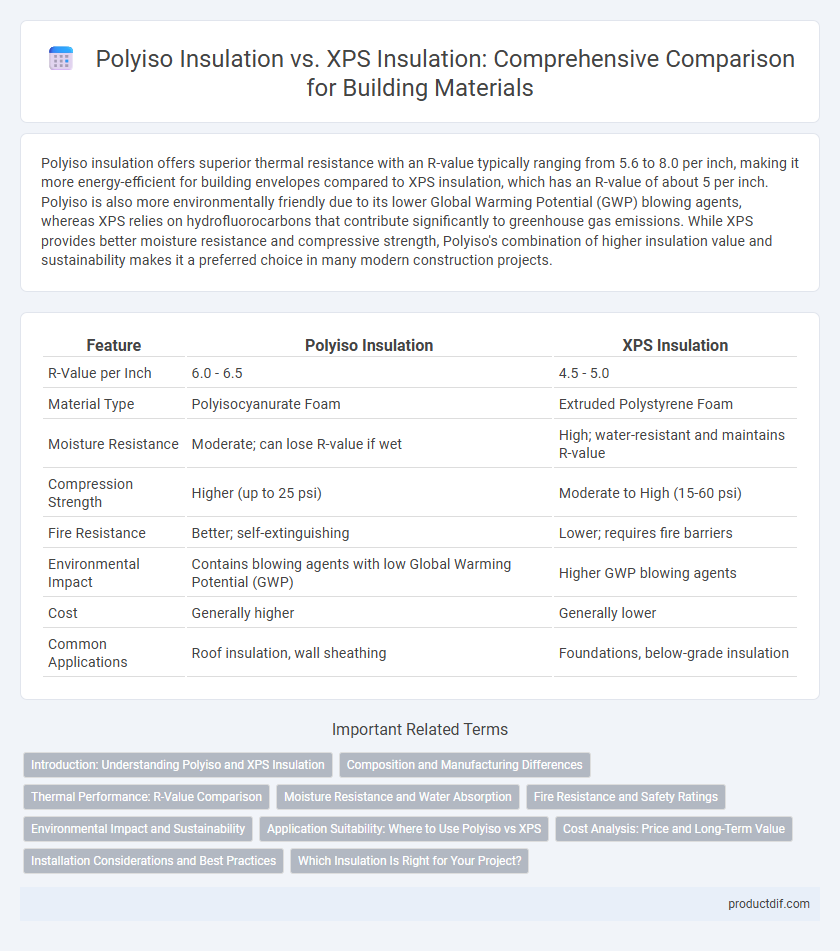

Polyiso insulation offers superior thermal resistance with an R-value typically ranging from 5.6 to 8.0 per inch, making it more energy-efficient for building envelopes compared to XPS insulation, which has an R-value of about 5 per inch. Polyiso is also more environmentally friendly due to its lower Global Warming Potential (GWP) blowing agents, whereas XPS relies on hydrofluorocarbons that contribute significantly to greenhouse gas emissions. While XPS provides better moisture resistance and compressive strength, Polyiso's combination of higher insulation value and sustainability makes it a preferred choice in many modern construction projects.

Table of Comparison

| Feature | Polyiso Insulation | XPS Insulation |

|---|---|---|

| R-Value per Inch | 6.0 - 6.5 | 4.5 - 5.0 |

| Material Type | Polyisocyanurate Foam | Extruded Polystyrene Foam |

| Moisture Resistance | Moderate; can lose R-value if wet | High; water-resistant and maintains R-value |

| Compression Strength | Higher (up to 25 psi) | Moderate to High (15-60 psi) |

| Fire Resistance | Better; self-extinguishing | Lower; requires fire barriers |

| Environmental Impact | Contains blowing agents with low Global Warming Potential (GWP) | Higher GWP blowing agents |

| Cost | Generally higher | Generally lower |

| Common Applications | Roof insulation, wall sheathing | Foundations, below-grade insulation |

Introduction: Understanding Polyiso and XPS Insulation

Polyiso insulation, made from polyurethane foam, offers high thermal resistance with an R-value typically ranging from 5.6 to 8 per inch, making it an efficient choice for reducing energy costs in building envelopes. XPS insulation, or extruded polystyrene, has a consistent R-value of about 5 per inch and provides strong moisture resistance, which is critical for below-grade and high-humidity applications. Understanding the differences in thermal performance, moisture resistance, and application suitability helps builders select the optimal insulation type for specific construction needs.

Composition and Manufacturing Differences

Polyiso insulation is composed of a rigid closed-cell foam made primarily from polyisocyanurate, which is produced by reacting methylene diphenyl diisocyanate (MDI) with polyols, resulting in a high thermal resistance material with a foil facing for added reflective properties. XPS insulation, or extruded polystyrene, is manufactured through an extrusion process that creates a dense, closed-cell foam structure composed of polystyrene beads melted and combined with blowing agents, offering moisture resistance and structural strength. The key manufacturing difference lies in polyiso's chemical reaction method producing superior fire resistance and R-value per inch, while XPS uses physical extrusion, yielding consistent moisture resistance and compressive strength.

Thermal Performance: R-Value Comparison

Polyiso insulation offers a higher initial R-value per inch, typically ranging from 6.0 to 6.5, compared to XPS insulation's R-value of around 5.0 per inch, making it more efficient for thermal resistance in colder climates. Over time, polyiso may experience R-value decline due to aging and moisture absorption, while XPS maintains more stable thermal performance with less degradation. Selecting between polyiso and XPS insulation depends on the specific application requirements, including moisture exposure and long-term thermal efficiency.

Moisture Resistance and Water Absorption

Polyiso insulation exhibits superior moisture resistance due to its closed-cell structure and foil facers, resulting in low water absorption rates typically below 1%. In contrast, XPS insulation, while also closed-cell, can absorb slightly more water over time, with water absorption rates generally ranging from 0.5% to 2%. Effective moisture resistance in Polyiso helps maintain its thermal performance and structural integrity in damp environments, whereas XPS may experience some reduction in R-value with prolonged exposure to moisture.

Fire Resistance and Safety Ratings

Polyiso insulation offers superior fire resistance with a higher limiting oxygen index (LOI) of around 28-30%, reducing flame spread and smoke development compared to XPS insulation, which typically has an LOI near 18-20%. Polyiso is often classified as Class A or Class 1 for fire safety, meeting stringent building codes, while XPS tends to have lower fire safety ratings and may require additional thermal barriers. The enhanced fire-resistant properties of Polyiso contribute to safer building envelopes by minimizing fire propagation and toxic smoke hazards.

Environmental Impact and Sustainability

Polyiso insulation offers a lower global warming potential (GWP) compared to XPS insulation due to its reduced use of hydrofluorocarbon (HFC) blowing agents, making it a more sustainable choice for energy-efficient buildings. XPS insulation, while providing excellent moisture resistance and thermal performance, relies heavily on HFCs that contribute significantly to ozone depletion and greenhouse gas emissions. Choosing polyiso insulation supports green building certifications such as LEED by minimizing environmental harm and promoting sustainable construction practices.

Application Suitability: Where to Use Polyiso vs XPS

Polyiso insulation excels in applications requiring high thermal resistance and moisture resistance, making it ideal for roof assemblies and above-grade walls. XPS insulation performs best in below-grade and foundation applications due to its superior compressive strength and water resistance. Choosing between Polyiso and XPS depends on factors like climate, exposure to moisture, and structural load demands.

Cost Analysis: Price and Long-Term Value

Polyiso insulation typically costs more upfront compared to XPS insulation but offers higher R-value per inch, which can translate to better energy savings over time. XPS insulation is generally less expensive initially but may have lower long-term value due to its lower thermal performance and potential moisture absorption. Evaluating life-cycle costs, including installation, energy efficiency, and durability, is essential for determining the best insulation investment.

Installation Considerations and Best Practices

Polyiso insulation offers a lightweight, easy-to-cut installation process that conforms well to irregular surfaces, reducing gaps and thermal bridging. XPS insulation requires careful handling due to its rigid boards, which are best installed with tight seams and staggered joints to enhance moisture resistance and structural integrity. Proper sealing with compatible tapes or adhesives is critical for both materials to maximize energy efficiency and prevent air infiltration.

Which Insulation Is Right for Your Project?

Polyiso insulation offers a higher R-value per inch, making it ideal for projects requiring superior thermal performance in tight spaces, while XPS insulation provides excellent moisture resistance and durability, suitable for below-grade applications. Consider the specific environmental conditions and building codes of your project to determine which material aligns best with energy efficiency and longevity goals. Evaluating factors such as cost, installation ease, and thermal barrier requirements will ensure the optimal choice between Polyiso and XPS insulation.

Polyiso Insulation vs XPS Insulation Infographic

productdif.com

productdif.com