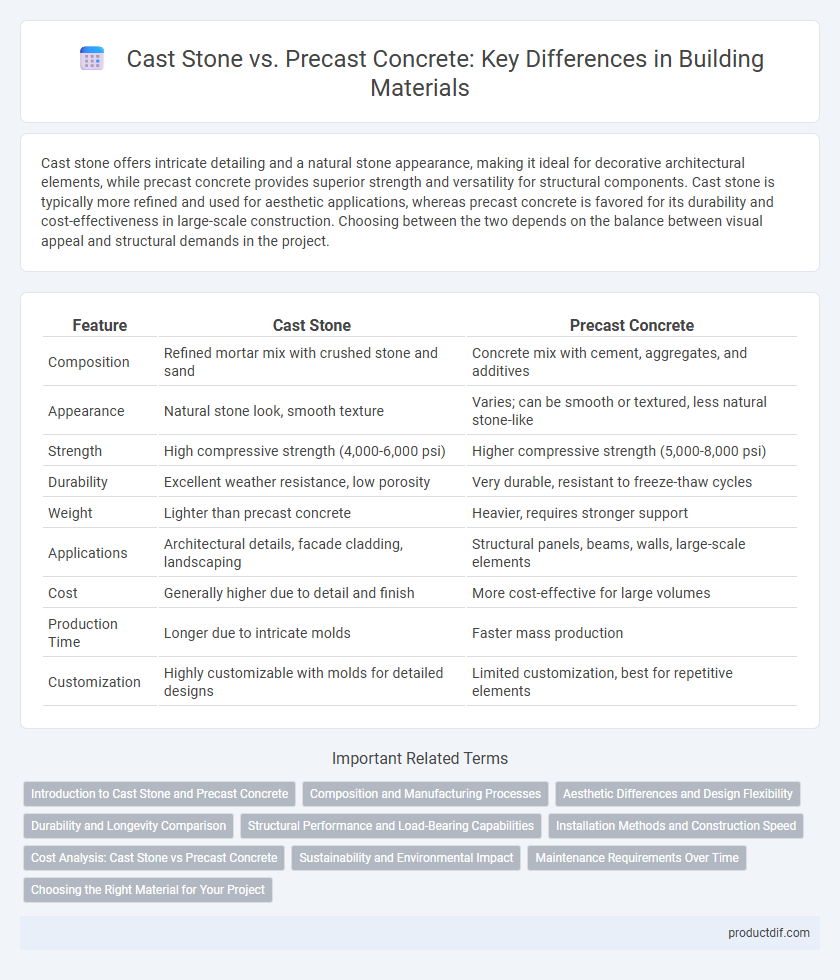

Cast stone offers intricate detailing and a natural stone appearance, making it ideal for decorative architectural elements, while precast concrete provides superior strength and versatility for structural components. Cast stone is typically more refined and used for aesthetic applications, whereas precast concrete is favored for its durability and cost-effectiveness in large-scale construction. Choosing between the two depends on the balance between visual appeal and structural demands in the project.

Table of Comparison

| Feature | Cast Stone | Precast Concrete |

|---|---|---|

| Composition | Refined mortar mix with crushed stone and sand | Concrete mix with cement, aggregates, and additives |

| Appearance | Natural stone look, smooth texture | Varies; can be smooth or textured, less natural stone-like |

| Strength | High compressive strength (4,000-6,000 psi) | Higher compressive strength (5,000-8,000 psi) |

| Durability | Excellent weather resistance, low porosity | Very durable, resistant to freeze-thaw cycles |

| Weight | Lighter than precast concrete | Heavier, requires stronger support |

| Applications | Architectural details, facade cladding, landscaping | Structural panels, beams, walls, large-scale elements |

| Cost | Generally higher due to detail and finish | More cost-effective for large volumes |

| Production Time | Longer due to intricate molds | Faster mass production |

| Customization | Highly customizable with molds for detailed designs | Limited customization, best for repetitive elements |

Introduction to Cast Stone and Precast Concrete

Cast stone is a highly versatile architectural building material made from a mixture of fine and coarse aggregates, cement, and integral color pigments, designed to simulate natural cut stone. Precast concrete involves casting concrete in reusable molds at a controlled factory environment before transporting it to the construction site, ensuring precise dimensions and quality. Both materials offer durability and aesthetic flexibility, with cast stone often favored for detailed ornamental elements and precast concrete valued for large-scale structural components.

Composition and Manufacturing Processes

Cast stone is composed of fine aggregates, cement, and mineral pigments, designed to mimic natural stone through a carefully controlled mixing process. Precast concrete consists of a mixture of coarse and fine aggregates, cement, water, and admixtures, produced in large molds under factory-controlled conditions. Both materials undergo curing, but cast stone emphasizes detailed surface finishes while precast concrete focuses on structural strength and dimensional accuracy.

Aesthetic Differences and Design Flexibility

Cast stone offers intricate textures and detailed finishes closely resembling natural stone, providing superior aesthetic appeal compared to precast concrete. Precast concrete allows for broader design flexibility with customizable shapes, sizes, and finishes, but typically features a more uniform and industrial look. The choice between the two depends on the desired architectural style and level of detail required for the project.

Durability and Longevity Comparison

Cast stone exhibits enhanced durability due to its dense composition and ability to resist weathering, making it ideal for architectural details exposed to harsh environments. Precast concrete offers superior longevity through its high compressive strength and uniform curing process, allowing it to withstand heavy structural loads over extended periods. Both materials provide long-lasting performance, but cast stone is often preferred for intricate design elements, while precast concrete excels in large-scale structural applications.

Structural Performance and Load-Bearing Capabilities

Cast stone offers enhanced aesthetic versatility while maintaining high compressive strength, making it suitable for both architectural detailing and moderate load-bearing applications. Precast concrete provides superior structural performance with higher load-bearing capacities, ideal for large-scale construction requiring robust support and durability under heavy loads. The choice between cast stone and precast concrete depends on specific project requirements, balancing visual appeal with the necessary structural integrity.

Installation Methods and Construction Speed

Cast stone installation involves skilled masonry techniques with mortar setting, which can extend construction timelines due to curing requirements. Precast concrete units offer faster installation through factory-controlled casting and quick onsite assembly using cranes and mechanical anchors. The accelerated construction speed with precast concrete enhances project efficiency and reduces labor costs in building material applications.

Cost Analysis: Cast Stone vs Precast Concrete

Cast stone typically incurs higher upfront costs compared to precast concrete due to its intricate manufacturing process and detailed finishes. Precast concrete offers cost advantages through faster production times and less labor-intensive installation, making it a budget-friendly option for large-scale projects. Long-term maintenance costs also favor precast concrete, which tends to have greater durability and lower repair expenses than cast stone.

Sustainability and Environmental Impact

Cast stone offers enhanced sustainability through its ability to utilize recycled aggregates and lower energy consumption during production compared to precast concrete. Precast concrete typically requires higher cement content, contributing to increased carbon emissions, whereas cast stone's composition can be optimized for reduced environmental impact. Both materials provide durability, but cast stone's adaptability in raw material sourcing supports greener construction practices.

Maintenance Requirements Over Time

Cast stone typically demands less frequent maintenance due to its dense composition and resistance to weathering, while precast concrete may require periodic sealing to prevent moisture infiltration and surface degradation. Over time, cast stone maintains its aesthetic appeal with minimal effort, whereas precast concrete is more prone to cracking and spalling, necessitating regular inspections and repairs. Proper maintenance schedules for both materials enhance longevity and preserve structural integrity in building applications.

Choosing the Right Material for Your Project

Cast stone offers superior detail and texture, ideal for intricate architectural designs, while precast concrete excels in strength and speed of installation for structural components. Evaluating project requirements such as aesthetic demands, load-bearing needs, and budget constraints ensures the appropriate selection between cast stone and precast concrete. Material durability, finish quality, and local availability also influence the decision-making process in building material selection.

Cast Stone vs Precast Concrete Infographic

productdif.com

productdif.com