Steel studs offer superior durability, resistance to termites, and consistent straightness compared to wood studs, making them ideal for commercial and high-moisture environments. Wood studs provide excellent thermal insulation and are easier to modify on-site, which benefits residential construction and remodeling projects. Choosing between steel and wood studs depends on factors like budget, environmental conditions, and specific project requirements.

Table of Comparison

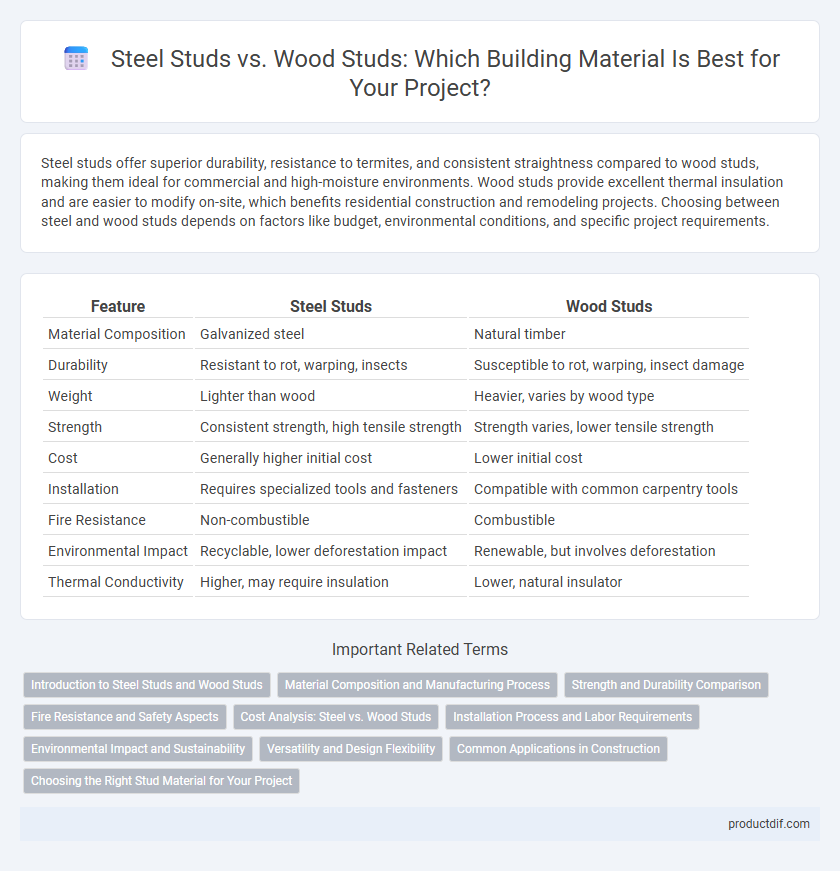

| Feature | Steel Studs | Wood Studs |

|---|---|---|

| Material Composition | Galvanized steel | Natural timber |

| Durability | Resistant to rot, warping, insects | Susceptible to rot, warping, insect damage |

| Weight | Lighter than wood | Heavier, varies by wood type |

| Strength | Consistent strength, high tensile strength | Strength varies, lower tensile strength |

| Cost | Generally higher initial cost | Lower initial cost |

| Installation | Requires specialized tools and fasteners | Compatible with common carpentry tools |

| Fire Resistance | Non-combustible | Combustible |

| Environmental Impact | Recyclable, lower deforestation impact | Renewable, but involves deforestation |

| Thermal Conductivity | Higher, may require insulation | Lower, natural insulator |

Introduction to Steel Studs and Wood Studs

Steel studs, composed primarily of galvanized steel, offer superior durability, resistance to fire, termites, and warping compared to traditional wood studs. Wood studs, typically made from softwoods like pine or fir, provide natural insulation properties and ease of modification during construction. Both steel and wood studs serve as fundamental framing materials, with steel favored in commercial buildings and wood prevalent in residential construction.

Material Composition and Manufacturing Process

Steel studs consist primarily of galvanized cold-rolled steel, offering high strength and resistance to warping, rot, and termites. Wood studs are composed of natural timber, typically pine or fir, which provides excellent thermal insulation but is susceptible to moisture damage and insect infestation. The manufacturing process for steel studs involves precise roll-forming from steel coils, ensuring uniform dimensions and durability, whereas wood studs are milled from logs, resulting in variability in grain and potential knots.

Strength and Durability Comparison

Steel studs exhibit superior strength and resist warping, twisting, and splitting compared to wood studs, making them ideal for load-bearing walls in commercial and residential construction. Wood studs provide natural flexibility and better insulation properties but are susceptible to moisture damage, termites, and fire, which can compromise long-term durability. The choice between steel and wood studs ultimately depends on project requirements, environmental conditions, and budget constraints.

Fire Resistance and Safety Aspects

Steel studs offer superior fire resistance compared to wood studs due to their non-combustible nature, reducing the risk of structural failure and fire spreading. Wood studs are flammable and can compromise building safety during a fire event, whereas steel studs maintain structural integrity under high temperatures. Fire-rated assemblies often incorporate steel studs to enhance overall fire safety and comply with building codes.

Cost Analysis: Steel vs. Wood Studs

Steel studs generally have a higher upfront cost compared to wood studs, with prices influenced by fluctuating steel market rates and manufacturing processes. Wood studs tend to be more affordable initially, but may incur additional expenses over time due to susceptibility to rot, pests, and warping. Long-term cost analysis must consider factors such as durability, maintenance requirements, and potential replacement costs when comparing steel studs versus wood studs.

Installation Process and Labor Requirements

Steel studs offer a faster installation process due to their lightweight design and pre-punched holes for easy wiring and plumbing, reducing overall labor time. Wood studs require more precise cutting and handling, as they are heavier and prone to warping, which can extend installation duration and increase labor costs. Contractors often prefer steel studs for projects with tight schedules and labor efficiency, while wood studs remain popular for traditional builds where artisanal carpentry is valued.

Environmental Impact and Sustainability

Steel studs offer greater sustainability due to their recyclability and resistance to warping, extending the building's lifespan and reducing waste. Wood studs, while renewable and biodegradable, contribute to deforestation and often require chemical treatments to enhance durability. Choosing steel studs significantly decreases environmental footprint by minimizing resource depletion and promoting circular economy in construction.

Versatility and Design Flexibility

Steel studs offer superior versatility and design flexibility compared to wood studs, as their uniform strength and resistance to warping allow for precise framing and intricate architectural designs. They accommodate a wide range of applications, including curved walls and non-standard layouts, without compromising structural integrity. Wood studs, while traditional, often face limitations in design adaptability due to natural inconsistencies and susceptibility to moisture and pests.

Common Applications in Construction

Steel studs are commonly used in commercial construction for non-load-bearing interior walls, offering advantages such as resistance to termites, fire, and moisture. Wood studs dominate residential construction, favored for load-bearing walls due to their ease of cutting, fastening, and availability. Both materials deliver structural support, but steel excels in environments requiring higher durability and compliance with fire codes.

Choosing the Right Stud Material for Your Project

Steel studs offer superior durability, resistance to fire, termites, and warping, making them ideal for commercial and high-moisture applications. Wood studs provide excellent thermal insulation, are easier to modify on-site, and often cost less for residential projects with typical framing needs. Selecting between steel and wood studs depends on project requirements including budget, environmental conditions, load-bearing needs, and long-term maintenance considerations.

Steel Studs vs Wood Studs Infographic

productdif.com

productdif.com