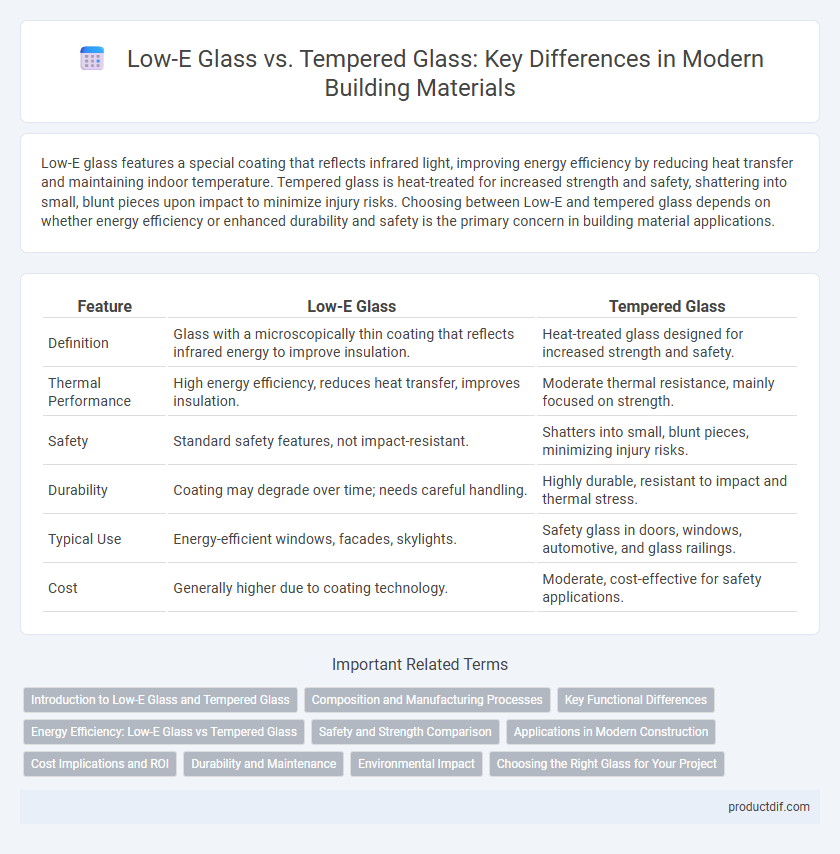

Low-E glass features a special coating that reflects infrared light, improving energy efficiency by reducing heat transfer and maintaining indoor temperature. Tempered glass is heat-treated for increased strength and safety, shattering into small, blunt pieces upon impact to minimize injury risks. Choosing between Low-E and tempered glass depends on whether energy efficiency or enhanced durability and safety is the primary concern in building material applications.

Table of Comparison

| Feature | Low-E Glass | Tempered Glass |

|---|---|---|

| Definition | Glass with a microscopically thin coating that reflects infrared energy to improve insulation. | Heat-treated glass designed for increased strength and safety. |

| Thermal Performance | High energy efficiency, reduces heat transfer, improves insulation. | Moderate thermal resistance, mainly focused on strength. |

| Safety | Standard safety features, not impact-resistant. | Shatters into small, blunt pieces, minimizing injury risks. |

| Durability | Coating may degrade over time; needs careful handling. | Highly durable, resistant to impact and thermal stress. |

| Typical Use | Energy-efficient windows, facades, skylights. | Safety glass in doors, windows, automotive, and glass railings. |

| Cost | Generally higher due to coating technology. | Moderate, cost-effective for safety applications. |

Introduction to Low-E Glass and Tempered Glass

Low-E glass features a microscopically thin, transparent coating that reduces heat transfer by reflecting infrared and ultraviolet light while maintaining visible light transmission, enhancing energy efficiency in buildings. Tempered glass undergoes a heat treatment process that increases its strength and causes it to break into small, blunt pieces for safety, making it ideal for impact-resistant applications. Both glass types improve building performance, with Low-E glass prioritizing thermal insulation and tempered glass focusing on durability and safety.

Composition and Manufacturing Processes

Low-E glass features a microscopically thin metallic coating applied to its surface during manufacturing, designed to reflect infrared and ultraviolet light while allowing visible light to pass through. Tempered glass is produced through a thermal tempering process involving rapid heating followed by controlled cooling, which enhances its strength and fracture resistance compared to standard annealed glass. The composition of tempered glass remains primarily silica-based, whereas Low-E glass incorporates additional coatings that significantly impact its thermal performance and energy efficiency.

Key Functional Differences

Low-E glass features a microscopically thin coating that reflects infrared energy, enhancing thermal insulation and reducing energy costs by minimizing heat transfer. Tempered glass undergoes controlled thermal or chemical treatments to increase strength, improving impact resistance and safety by shattering into small, blunt pieces upon breakage. The primary functional difference lies in Low-E glass's energy efficiency and UV protection, while tempered glass focuses on mechanical durability and safety performance.

Energy Efficiency: Low-E Glass vs Tempered Glass

Low-E glass significantly enhances energy efficiency by reflecting infrared heat while allowing natural light to enter, reducing heating and cooling costs. Tempered glass offers superior strength and safety but lacks the thermal insulation properties of Low-E coatings. Choosing Low-E glass improves building energy performance by minimizing heat transfer compared to standard tempered glass.

Safety and Strength Comparison

Low-E glass enhances energy efficiency by reflecting infrared light while maintaining visibility but offers moderate impact resistance compared to tempered glass. Tempered glass undergoes heat treatment to achieve superior mechanical strength, resisting breakage and shattering into small, less harmful pieces, thereby providing enhanced safety. In applications requiring both safety and strength, tempered glass is preferred, though Low-E coatings can be applied to tempered glass to balance energy efficiency with durability.

Applications in Modern Construction

Low-E glass enhances energy efficiency in modern construction by reflecting infrared radiation while allowing visible light, ideal for windows in residential and commercial buildings seeking thermal insulation. Tempered glass provides superior strength and safety by undergoing heat treatment, making it suitable for structural applications such as facades, skylights, and interior partitions where impact resistance is crucial. Combining Low-E coatings with tempered glass results in optimized building envelopes that improve energy performance without compromising durability or safety.

Cost Implications and ROI

Low-E glass, known for its energy-efficient properties, typically incurs a higher initial cost compared to tempered glass but delivers significant long-term savings on heating and cooling expenses, resulting in a favorable ROI over time. Tempered glass, while generally more affordable upfront, lacks the same insulation benefits, which can lead to higher energy costs and reduced overall savings. Investing in Low-E glass enhances building performance and sustainability, ultimately providing better cost-effectiveness despite the steeper initial expense.

Durability and Maintenance

Low-E glass features a thin metallic coating that enhances energy efficiency while maintaining durability against environmental elements, requiring minimal upkeep to preserve its insulating properties. Tempered glass undergoes a heat treatment process that significantly increases its strength and resistance to impact, making it highly durable but sometimes more prone to surface damage requiring occasional cleaning to prevent scratches. Both materials offer robust durability, yet Low-E glass demands less frequent maintenance due to its protective coating, whereas tempered glass's toughness supports sustained structural integrity in high-stress applications.

Environmental Impact

Low-E glass significantly reduces energy consumption by reflecting infrared heat while allowing visible light to pass through, enhancing building insulation and lowering heating and cooling demands. Tempered glass, known for its strength and safety, has a higher energy footprint due to the intense heat treatment required during manufacturing. Opting for Low-E glass contributes more effectively to reducing carbon emissions and minimizing overall environmental impact in building projects.

Choosing the Right Glass for Your Project

Low-E glass offers superior energy efficiency by minimizing heat transfer, making it ideal for projects aiming to reduce energy costs and enhance indoor comfort. Tempered glass provides enhanced safety and strength, suitable for applications requiring impact resistance and compliance with building codes. Selecting between Low-E and tempered glass depends on project priorities such as thermal performance versus durability and safety requirements.

Low-E glass vs Tempered glass Infographic

productdif.com

productdif.com