Grade 5 bolts are made from medium carbon steel, offering moderate strength suitable for automotive and general construction applications where high tensile strength is not crucial. Grade 8 bolts are manufactured from medium carbon alloy steel, heat-treated for superior hardness and tensile strength, making them ideal for heavy-duty and structural applications requiring maximum durability. Choosing between Grade 5 and Grade 8 bolts depends on the specific load requirements and environmental conditions of the building material project.

Table of Comparison

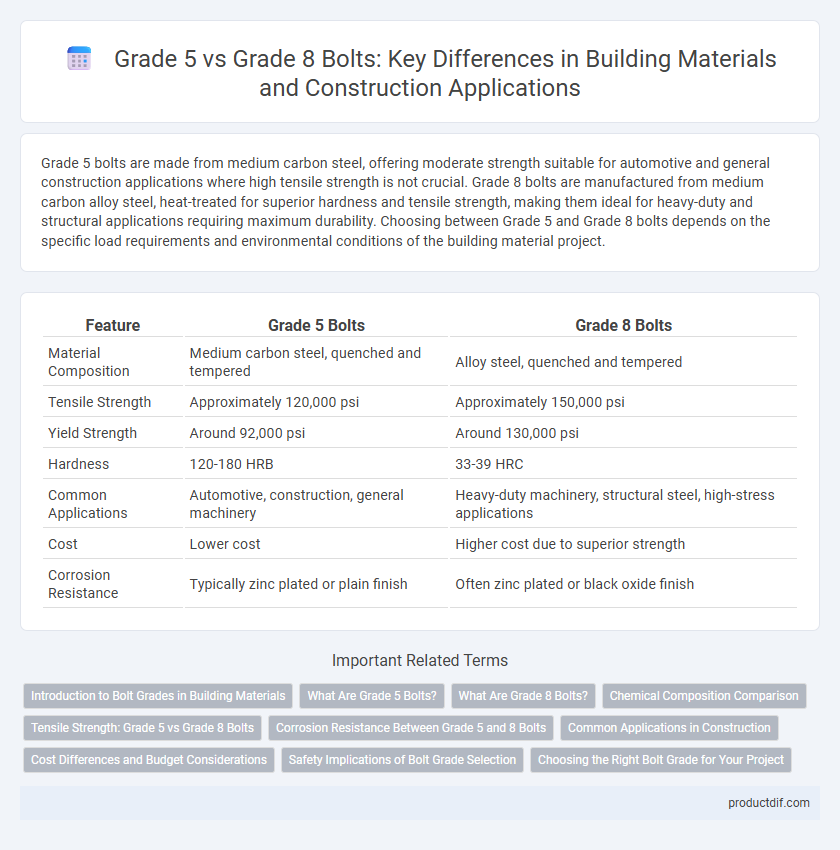

| Feature | Grade 5 Bolts | Grade 8 Bolts |

|---|---|---|

| Material Composition | Medium carbon steel, quenched and tempered | Alloy steel, quenched and tempered |

| Tensile Strength | Approximately 120,000 psi | Approximately 150,000 psi |

| Yield Strength | Around 92,000 psi | Around 130,000 psi |

| Hardness | 120-180 HRB | 33-39 HRC |

| Common Applications | Automotive, construction, general machinery | Heavy-duty machinery, structural steel, high-stress applications |

| Cost | Lower cost | Higher cost due to superior strength |

| Corrosion Resistance | Typically zinc plated or plain finish | Often zinc plated or black oxide finish |

Introduction to Bolt Grades in Building Materials

Bolt grades in building materials indicate the tensile strength and durability of fasteners, essential for structural integrity. Grade 5 bolts are medium-strength, typically made from chromium-vanadium steel, offering tensile strength around 120,000 psi, suitable for general construction applications. Grade 8 bolts, forged from medium carbon alloy steel, provide higher tensile strength approximately 150,000 psi, making them ideal for heavy-duty or high-stress building components.

What Are Grade 5 Bolts?

Grade 5 bolts are medium-strength fasteners made from hardened carbon steel with a tensile strength of approximately 120,000 psi, commonly used in automotive and construction applications. These bolts feature a three-dash head marking to indicate their grade and provide a balance between strength and cost-effectiveness. Grade 5 bolts offer reliable performance for general-purpose fastening where moderate strength is sufficient.

What Are Grade 8 Bolts?

Grade 8 bolts are high-strength fasteners made from medium carbon alloy steel, quenched and tempered to achieve superior tensile strength around 150,000 psi. These bolts are commonly used in heavy-duty applications such as automotive, construction, and industrial machinery where maximum durability and resistance to shear forces are required. Their higher hardness and improved fatigue resistance make Grade 8 bolts ideal for securing critical components under extreme stress conditions.

Chemical Composition Comparison

Grade 5 bolts feature a chemical composition with approximately 0.55% carbon, 0.60-0.90% manganese, and trace amounts of phosphorus and sulfur, delivering balanced strength and ductility. Grade 8 bolts contain a higher carbon content around 0.55-0.70%, increased manganese up to 1.20%, and small quantities of chromium and molybdenum, enhancing hardness and tensile strength. The presence of these alloying elements in Grade 8 bolts results in superior resistance to wear and fatigue compared to Grade 5 bolts, making them suitable for heavy-duty applications.

Tensile Strength: Grade 5 vs Grade 8 Bolts

Grade 5 bolts have a tensile strength of approximately 120,000 psi, making them suitable for medium-strength applications. Grade 8 bolts offer a higher tensile strength around 150,000 psi, providing enhanced durability and performance in heavy-duty construction projects. The increased tensile strength of Grade 8 bolts allows them to withstand greater stress, making them ideal for critical structural components requiring superior load-bearing capacity.

Corrosion Resistance Between Grade 5 and 8 Bolts

Grade 8 bolts exhibit superior corrosion resistance compared to Grade 5 bolts due to their higher carbon and alloy content, often enhanced with additional coatings such as zinc plating or black oxide finishes. Grade 5 bolts, while moderately resistant, are more prone to rust and degradation when exposed to harsh environments, particularly in outdoor or marine applications. Selecting Grade 8 bolts ensures enhanced durability and longer lifespan in corrosive conditions, critical for maintaining structural integrity in building material applications.

Common Applications in Construction

Grade 5 bolts, made from medium carbon steel and quenched and tempered, are commonly used in structural applications such as steel frameworks, machinery assemblies, and automotive components due to their balanced strength and durability. Grade 8 bolts, manufactured from medium carbon alloy steel with higher tensile strength, are preferred for heavy-load applications including bridge construction, heavy equipment, and critical structural connections where maximum shear strength and fatigue resistance are essential. The choice between Grade 5 and Grade 8 bolts depends on the required load capacity, with Grade 8 offering superior performance for demanding construction projects.

Cost Differences and Budget Considerations

Grade 5 bolts, typically made from medium carbon steel and hardened through quenching and tempering, offer a cost-effective solution for moderate-strength applications, usually priced lower than Grade 8 bolts. Grade 8 bolts, crafted from medium carbon alloy steel with a heat treatment process for higher tensile strength, carry a higher price point due to their superior durability and capacity to withstand heavy loads. When budgeting for construction projects, selecting Grade 5 bolts can reduce expenses without compromising safety in less demanding environments, whereas Grade 8 bolts justify the higher investment for critical structural components requiring maximum strength.

Safety Implications of Bolt Grade Selection

Grade 8 bolts offer higher tensile strength compared to Grade 5 bolts, making them more suitable for critical structural applications where safety is paramount. Using Grade 5 bolts in high-stress environments increases the risk of failure, potentially leading to structural damage or accidents. Selecting the appropriate bolt grade ensures optimal load-bearing capacity and minimizes the likelihood of mechanical failure in building materials.

Choosing the Right Bolt Grade for Your Project

Grade 5 bolts, made from medium carbon steel, offer a tensile strength of approximately 120,000 psi and are suitable for automotive and structural applications where moderate strength is required. Grade 8 bolts, composed of medium carbon alloy steel, provide a higher tensile strength of about 150,000 psi, making them ideal for heavy-duty projects demanding superior durability and resistance to shear forces. Selecting the appropriate bolt grade depends on the load requirements, environmental conditions, and safety factors to ensure optimal performance and longevity in your building project.

Grade 5 Bolts vs Grade 8 Bolts Infographic

productdif.com

productdif.com