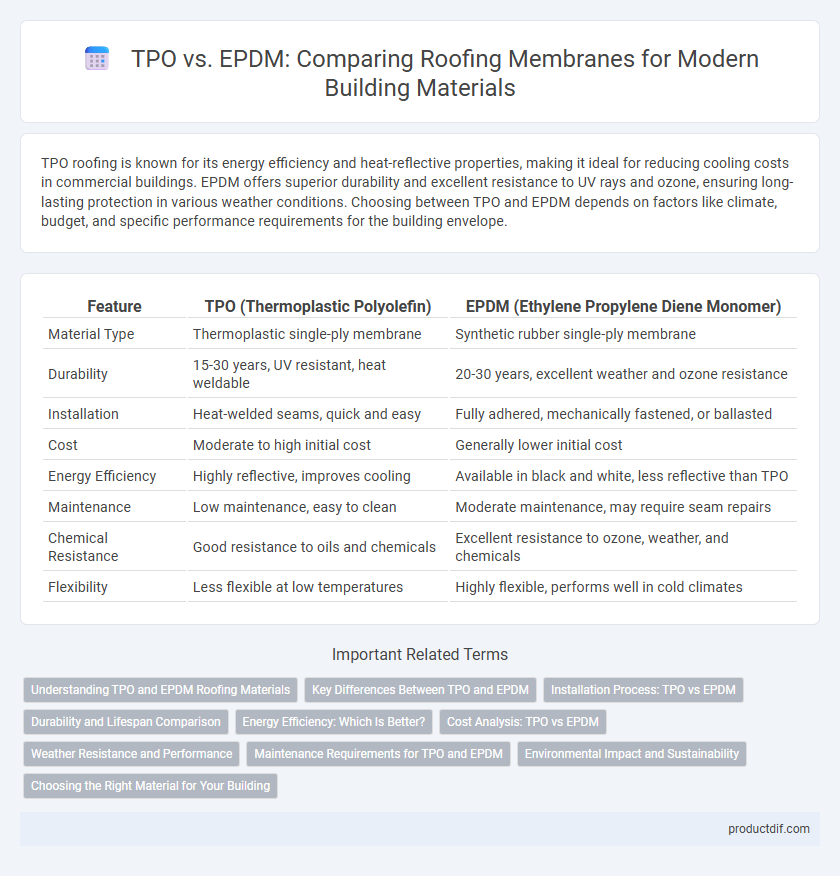

TPO roofing is known for its energy efficiency and heat-reflective properties, making it ideal for reducing cooling costs in commercial buildings. EPDM offers superior durability and excellent resistance to UV rays and ozone, ensuring long-lasting protection in various weather conditions. Choosing between TPO and EPDM depends on factors like climate, budget, and specific performance requirements for the building envelope.

Table of Comparison

| Feature | TPO (Thermoplastic Polyolefin) | EPDM (Ethylene Propylene Diene Monomer) |

|---|---|---|

| Material Type | Thermoplastic single-ply membrane | Synthetic rubber single-ply membrane |

| Durability | 15-30 years, UV resistant, heat weldable | 20-30 years, excellent weather and ozone resistance |

| Installation | Heat-welded seams, quick and easy | Fully adhered, mechanically fastened, or ballasted |

| Cost | Moderate to high initial cost | Generally lower initial cost |

| Energy Efficiency | Highly reflective, improves cooling | Available in black and white, less reflective than TPO |

| Maintenance | Low maintenance, easy to clean | Moderate maintenance, may require seam repairs |

| Chemical Resistance | Good resistance to oils and chemicals | Excellent resistance to ozone, weather, and chemicals |

| Flexibility | Less flexible at low temperatures | Highly flexible, performs well in cold climates |

Understanding TPO and EPDM Roofing Materials

TPO (Thermoplastic Olefin) roofing materials offer excellent UV resistance and heat reflectivity, making them highly energy-efficient for commercial buildings. EPDM (Ethylene Propylene Diene Monomer) is known for its superior durability and weather resistance, especially in colder climates, with a lifespan often exceeding 30 years. Both materials provide flexible, waterproof membrane options, but TPO typically features a lighter color that reduces cooling costs, whereas EPDM's black surface excels in absorbing heat to prevent ice dam formation.

Key Differences Between TPO and EPDM

TPO (Thermoplastic Olefin) roofing membranes offer superior heat reflection and energy efficiency compared to EPDM (Ethylene Propylene Diene Monomer), which excels in weather resistance and durability. TPO's welded seams provide enhanced waterproofing, while EPDM relies on adhesive or tape-based seams that may require more maintenance. Cost-wise, EPDM is generally more affordable upfront, but TPO's long-term energy savings and lifespan can provide better value over time.

Installation Process: TPO vs EPDM

TPO roofing membranes feature a heat-welded seam installation process, creating strong, watertight bonds that reduce the risk of leaks and enhance durability. EPDM installation typically involves adhesive or mechanical fastening with tape or liquid adhesives, resulting in a quicker but potentially less seamless finish. The choice between TPO and EPDM installation depends on project requirements for speed, weather conditions, and long-term performance.

Durability and Lifespan Comparison

TPO roofing membranes typically offer a lifespan of 15 to 30 years, exhibiting strong resistance to UV rays, chemical exposure, and punctures, making them durable in various climates. EPDM membranes often last 20 to 30 years or more, with exceptional flexibility and proven resilience against ozone, weathering, and temperature extremes. Both materials deliver robust durability, but EPDM generally outperforms TPO in extreme temperature fluctuations and long-term weathering resistance.

Energy Efficiency: Which Is Better?

TPO roofing membranes typically offer higher energy efficiency due to their reflective white surface that reduces heat absorption and lowers cooling costs. EPDM has excellent durability but absorbs more heat, leading to increased energy consumption in warm climates. Energy performance ratings and local climate factors should guide the choice between TPO and EPDM for optimal building energy efficiency.

Cost Analysis: TPO vs EPDM

TPO roofing systems generally offer lower initial installation costs compared to EPDM due to their faster application and lighter materials. EPDM materials tend to be more expensive upfront but provide longer life expectancy and superior weather resistance, potentially reducing replacement frequency. When evaluating long-term expenses, TPO's energy efficiency benefits can result in lower utility bills, while EPDM's durability minimizes maintenance and repair costs.

Weather Resistance and Performance

TPO roofing membranes offer superior UV and chemical resistance, maintaining flexibility and color stability in extreme weather conditions, making them ideal for hot, sunny climates. EPDM excels in cold weather resistance and remains highly durable against hail and wind, ensuring long-term waterproofing and elasticity in fluctuating temperatures. Both materials provide strong weather resistance, but TPO's reflective properties contribute to energy efficiency, while EPDM's proven resilience offers consistent performance in harsh, variable environments.

Maintenance Requirements for TPO and EPDM

TPO (Thermoplastic Olefin) roofing requires periodic cleaning to prevent dirt and debris buildup that can cause surface degradation, while its seams benefit from regular inspections to maintain their heat-welded integrity. EPDM (Ethylene Propylene Diene Monomer) demands less intensive maintenance due to its inherent durability and resistance to ultraviolet rays, though its seams, typically adhered with tape or contact cement, should be checked for potential adhesive failures. Both materials benefit from routine checks to address punctures or damages promptly, extending the roof's lifespan.

Environmental Impact and Sustainability

Thermoplastic Olefin (TPO) roofing membranes offer superior recyclability compared to Ethylene Propylene Diene Monomer (EPDM), contributing to reduced landfill waste and lower environmental footprint. EPDM's production involves more energy-intensive processes and emits higher levels of greenhouse gases, whereas TPO manufacturing typically uses fewer harmful chemicals and results in lower VOC emissions. Both materials provide long service life, but TPO's ability to be heat-welded enhances repairability and extends overall roof lifespan, promoting sustainability in building materials.

Choosing the Right Material for Your Building

TPO (Thermoplastic Olefin) roofing offers superior UV resistance and energy efficiency, making it ideal for buildings in sunny climates seeking lower cooling costs. EPDM (Ethylene Propylene Diene Monomer) excels in durability and flexibility, providing excellent resistance to extreme weather and chemicals, suitable for buildings in harsh weather conditions. Selecting between TPO and EPDM depends on the building's environmental exposure, budget, and long-term maintenance goals to ensure optimal performance and lifespan.

TPO vs EPDM Infographic

productdif.com

productdif.com