Polyurethane foam offers superior insulation and durability compared to polystyrene foam, making it ideal for energy-efficient building projects. Polystyrene foam, while cost-effective and lightweight, often lacks the same level of thermal resistance and structural strength. Choosing between these materials depends on the specific insulation needs, budget constraints, and long-term performance expectations of the construction.

Table of Comparison

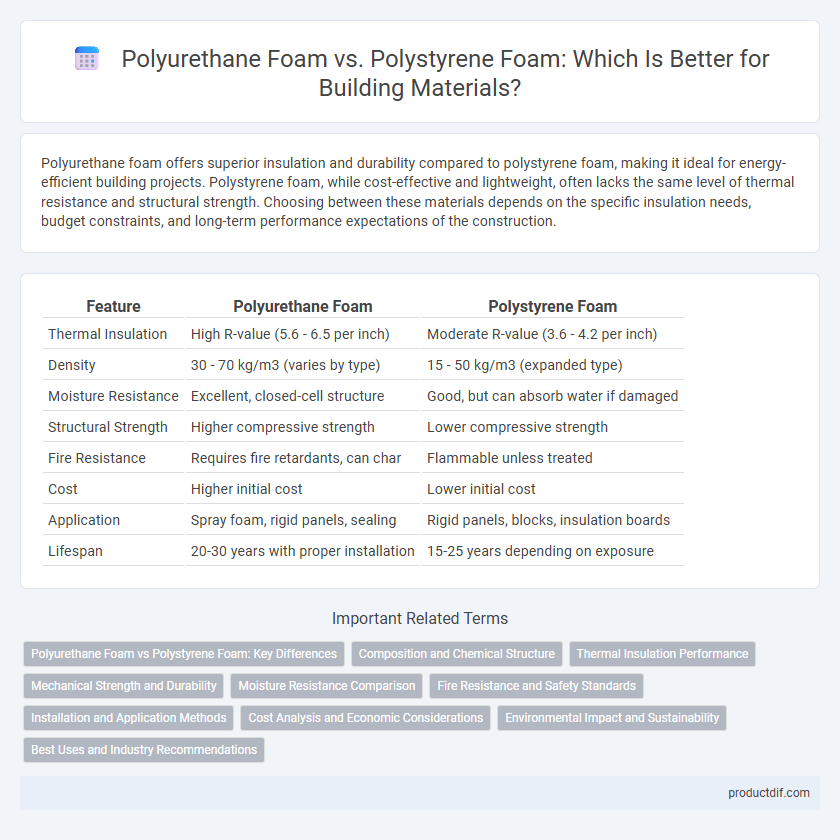

| Feature | Polyurethane Foam | Polystyrene Foam |

|---|---|---|

| Thermal Insulation | High R-value (5.6 - 6.5 per inch) | Moderate R-value (3.6 - 4.2 per inch) |

| Density | 30 - 70 kg/m3 (varies by type) | 15 - 50 kg/m3 (expanded type) |

| Moisture Resistance | Excellent, closed-cell structure | Good, but can absorb water if damaged |

| Structural Strength | Higher compressive strength | Lower compressive strength |

| Fire Resistance | Requires fire retardants, can char | Flammable unless treated |

| Cost | Higher initial cost | Lower initial cost |

| Application | Spray foam, rigid panels, sealing | Rigid panels, blocks, insulation boards |

| Lifespan | 20-30 years with proper installation | 15-25 years depending on exposure |

Polyurethane Foam vs Polystyrene Foam: Key Differences

Polyurethane foam offers superior insulation with an R-value ranging from 6 to 7 per inch, compared to polystyrene foam's R-value of 3.6 to 5, making polyurethane more energy-efficient for building applications. Its closed-cell structure provides enhanced moisture resistance and durability, whereas polystyrene foam, available in expanded (EPS) and extruded (XPS) forms, varies in density and strength, with XPS offering better performance than EPS. Polyurethane foam is more versatile for spray applications and complex shapes, while polystyrene foam excels in rigid panel insulation and cost-effectiveness.

Composition and Chemical Structure

Polyurethane foam is a polymer composed of organic units linked by carbamate (urethane) bonds, formed through the reaction of polyols with diisocyanates, offering flexibility and varying densities. Polystyrene foam consists of polystyrene polymers derived from the polymerization of styrene monomers, characterized by a rigid, closed-cell structure with excellent thermal insulation properties. The differing chemical structures influence their mechanical properties, thermal resistance, and applications in building insulation and cushioning.

Thermal Insulation Performance

Polyurethane foam offers superior thermal insulation performance compared to polystyrene foam due to its lower thermal conductivity, typically around 0.020 W/m*K versus 0.030 W/m*K for expanded polystyrene (EPS). This enhanced insulation capability results from polyurethane's closed-cell structure, which effectively reduces heat transfer and improves energy efficiency in building envelopes. Polystyrene foam, while less insulating, provides cost advantages and moisture resistance, but polyurethane remains the preferred material for maximizing thermal insulation in construction projects.

Mechanical Strength and Durability

Polyurethane foam exhibits higher mechanical strength and superior durability compared to polystyrene foam, making it ideal for load-bearing insulation applications. Its closed-cell structure provides enhanced resistance to compression, impact, and moisture damage, extending the lifespan of construction materials. Polystyrene foam, while lightweight and cost-effective, tends to have lower compressive strength and is more susceptible to environmental degradation over time.

Moisture Resistance Comparison

Polyurethane foam exhibits superior moisture resistance compared to polystyrene foam, making it more effective for applications in damp environments and preventing water absorption that can lead to structural degradation. The closed-cell structure of polyurethane foam minimizes water penetration, whereas polystyrene foam's open-cell variants are more prone to moisture infiltration and mold growth. This characteristic makes polyurethane foam a preferred insulation material in construction projects requiring high durability against humidity and water exposure.

Fire Resistance and Safety Standards

Polyurethane foam typically exhibits lower fire resistance compared to polystyrene foam, as it tends to ignite more easily and produce toxic smoke during combustion. Polystyrene foam, especially when treated with fire-retardant additives, meets higher safety standards such as ASTM E84 and NFPA 286, ensuring better performance in fire scenarios. Building codes often prefer polystyrene foam for insulation in commercial constructions due to its superior flame spread and smoke development characteristics.

Installation and Application Methods

Polyurethane foam offers superior adhesion and seamless insulation through spray application, allowing it to expand and fill gaps for airtight seals in walls, roofs, and crawl spaces. Polystyrene foam typically involves rigid board installation using mechanical fasteners or adhesives, providing stable and moisture-resistant insulation mainly in wall sheathing, foundations, and insulating concrete forms. The choice between these foams depends on project requirements for ease of installation, expansion properties, and specific thermal performance in building envelopes.

Cost Analysis and Economic Considerations

Polyurethane foam typically offers higher thermal insulation value per inch compared to polystyrene foam, potentially reducing long-term energy costs despite its higher initial price. Polystyrene foam is generally more cost-effective upfront and widely used in construction for budget-sensitive projects due to its lower material and installation expenses. Economic considerations also include durability and application-specific efficiency, where polyurethane's superior moisture resistance can minimize maintenance and replacement costs over time.

Environmental Impact and Sustainability

Polyurethane foam, derived from petroleum-based chemicals, presents challenges in biodegradability and often releases harmful volatile organic compounds (VOCs) during production and disposal. Polystyrene foam, especially expanded polystyrene (EPS), is notoriously persistent in the environment, contributing significantly to plastic pollution due to its resistance to degradation and difficulty in recycling. Sustainable alternatives and improved recycling technologies are critical for reducing the ecological footprint of both foam materials in building applications.

Best Uses and Industry Recommendations

Polyurethane foam excels in insulation for walls, ceilings, and roofing due to its superior thermal resistance and moisture barrier properties, making it ideal for energy-efficient buildings and HVAC applications. Polystyrene foam, available in expanded (EPS) and extruded (XPS) forms, is recommended for use in roofing insulation, below-grade thermal insulation, and as a lightweight structural fill because of its rigidity and cost-effectiveness. Industry standards suggest selecting polyurethane for high-performance insulation needs and moisture-prone environments, while polystyrene is preferred for applications requiring compressive strength and budget-friendly solutions.

Polyurethane foam vs Polystyrene foam Infographic

productdif.com

productdif.com