Light-gauge steel framing offers superior durability and resistance to termites, fire, and moisture compared to traditional wood framing, making it ideal for long-lasting, low-maintenance construction. Its precision in manufacturing ensures consistent quality and faster assembly on-site, reducing labor costs and construction time. Wood framing remains popular for its cost-effectiveness and ease of customization but is more susceptible to warping, pests, and decay, which can increase maintenance expenses over time.

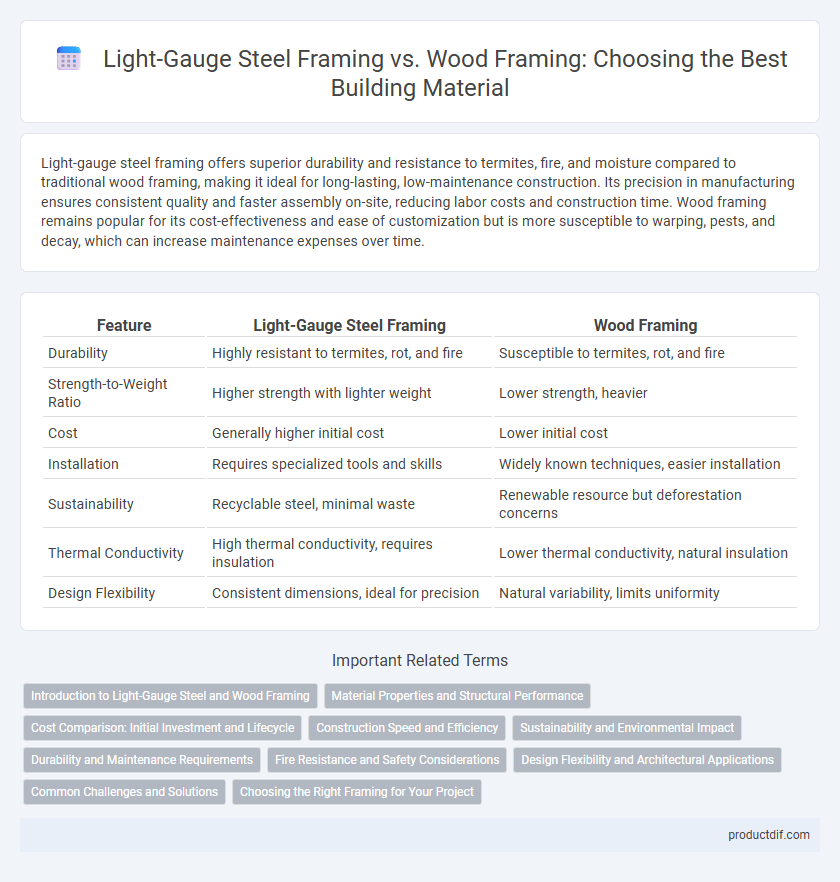

Table of Comparison

| Feature | Light-Gauge Steel Framing | Wood Framing |

|---|---|---|

| Durability | Highly resistant to termites, rot, and fire | Susceptible to termites, rot, and fire |

| Strength-to-Weight Ratio | Higher strength with lighter weight | Lower strength, heavier |

| Cost | Generally higher initial cost | Lower initial cost |

| Installation | Requires specialized tools and skills | Widely known techniques, easier installation |

| Sustainability | Recyclable steel, minimal waste | Renewable resource but deforestation concerns |

| Thermal Conductivity | High thermal conductivity, requires insulation | Lower thermal conductivity, natural insulation |

| Design Flexibility | Consistent dimensions, ideal for precision | Natural variability, limits uniformity |

Introduction to Light-Gauge Steel and Wood Framing

Light-gauge steel framing consists of thin, cold-formed steel sections designed for structural support in residential and commercial buildings, offering high strength-to-weight ratio and resistance to pests and fire. Wood framing, traditionally composed of dimensional lumber such as 2x4s and 2x6s, is valued for its natural insulation properties and ease of customization on site. Both materials serve as primary structural frameworks, influencing building durability, construction speed, and environmental impact.

Material Properties and Structural Performance

Light-gauge steel framing offers superior strength-to-weight ratio and enhanced durability compared to wood framing, providing resistance to warping, termites, and fire. Steel's uniformity ensures consistent load-bearing capacity, allowing for longer spans and more flexible architectural designs. Wood framing, while having natural insulation properties and ease of modification on-site, is more susceptible to moisture-related issues and dimensional instability, impacting long-term structural performance.

Cost Comparison: Initial Investment and Lifecycle

Light-gauge steel framing generally requires a higher initial investment compared to traditional wood framing due to material costs and specialized labor. Over the lifecycle, steel framing offers reduced maintenance expenses and enhanced durability, resulting in cost savings from fewer repairs and longer service life. Wood framing often incurs lower upfront costs but can lead to higher long-term expenses related to pest damage, rot, and increased maintenance.

Construction Speed and Efficiency

Light-gauge steel framing significantly accelerates construction speed compared to wood framing due to prefabricated components that ensure precise fit and minimal on-site adjustments. This method reduces labor time and material waste, improving overall project efficiency and reducing delays caused by weather or pest damage common in wood structures. Enhanced durability and consistent quality of light-gauge steel framing contribute to faster project completion and long-term cost savings.

Sustainability and Environmental Impact

Light-gauge steel framing offers superior sustainability compared to wood framing due to its high recyclability and reduced waste generation during construction. Wood framing, while renewable, contributes to deforestation and carbon emissions, impacting long-term environmental health. Steel also ensures greater durability and resistance to pests, minimizing material replacement and environmental resource consumption over time.

Durability and Maintenance Requirements

Light-gauge steel framing offers superior durability compared to wood framing, resisting warping, termites, and fire without compromising structural integrity. Steel framing requires minimal maintenance, avoiding issues like rot and insect damage that commonly affect wood. Wood framing demands regular inspections and treatments to maintain longevity, increasing overall upkeep costs over time.

Fire Resistance and Safety Considerations

Light-gauge steel framing offers superior fire resistance compared to wood framing due to its non-combustible nature, significantly reducing the risk of structural failure during a fire. Wood framing is combustible and can ignite, potentially compromising building safety and increasing fire spread. Fire-resistant coatings and insulation can enhance steel framing safety, while wood requires additional fire-retardant treatments to meet safety standards.

Design Flexibility and Architectural Applications

Light-gauge steel framing offers superior design flexibility compared to wood framing, enabling architects to create more complex shapes and longer spans without sacrificing structural integrity. Its uniformity and precision allow for greater adaptability in innovative architectural applications, including curved walls and open floor plans. Wood framing, while traditional and cost-effective, often limits design possibilities due to natural material constraints and susceptibility to warping.

Common Challenges and Solutions

Light-gauge steel framing often faces challenges such as thermal bridging, corrosion, and complex fastening requirements, which can compromise structural integrity and energy efficiency. Wood framing encounters issues like susceptibility to moisture damage, termites, and dimensional instability, leading to warping and decay. Solutions for steel include using thermal breaks, galvanized coatings, and specialized fasteners, while wood framing benefits from pressure-treated lumber, moisture barriers, and regular maintenance.

Choosing the Right Framing for Your Project

Light-gauge steel framing offers superior durability, resistance to pests, and fireproof qualities compared to traditional wood framing, making it an ideal choice for projects requiring long-term structural integrity. Wood framing provides flexibility, ease of modification, and is typically more cost-effective, appealing to residential builds and projects with tighter budgets. Considering factors such as project scale, environmental conditions, and budget constraints ensures selecting framing materials that optimize performance and sustainability.

Light-gauge steel framing vs Wood framing Infographic

productdif.com

productdif.com