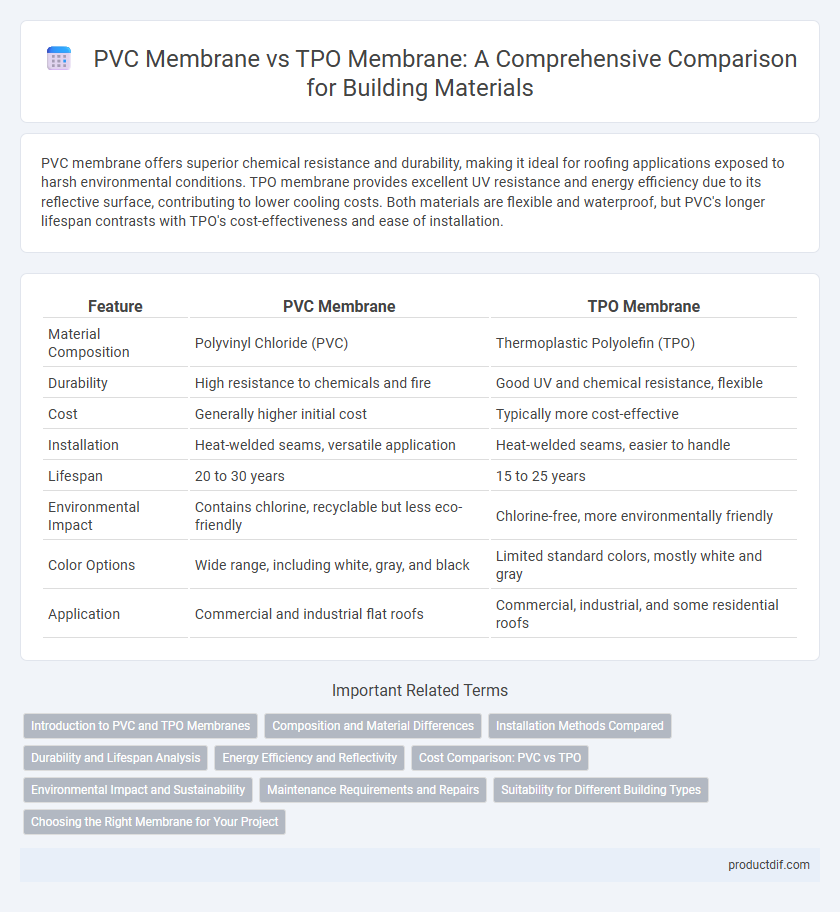

PVC membrane offers superior chemical resistance and durability, making it ideal for roofing applications exposed to harsh environmental conditions. TPO membrane provides excellent UV resistance and energy efficiency due to its reflective surface, contributing to lower cooling costs. Both materials are flexible and waterproof, but PVC's longer lifespan contrasts with TPO's cost-effectiveness and ease of installation.

Table of Comparison

| Feature | PVC Membrane | TPO Membrane |

|---|---|---|

| Material Composition | Polyvinyl Chloride (PVC) | Thermoplastic Polyolefin (TPO) |

| Durability | High resistance to chemicals and fire | Good UV and chemical resistance, flexible |

| Cost | Generally higher initial cost | Typically more cost-effective |

| Installation | Heat-welded seams, versatile application | Heat-welded seams, easier to handle |

| Lifespan | 20 to 30 years | 15 to 25 years |

| Environmental Impact | Contains chlorine, recyclable but less eco-friendly | Chlorine-free, more environmentally friendly |

| Color Options | Wide range, including white, gray, and black | Limited standard colors, mostly white and gray |

| Application | Commercial and industrial flat roofs | Commercial, industrial, and some residential roofs |

Introduction to PVC and TPO Membranes

PVC membranes are durable synthetic roofing materials composed of polyvinyl chloride, known for their chemical resistance, flexibility, and ease of installation. TPO membranes, made from thermoplastic olefin, offer excellent UV resistance, reflectivity, and energy efficiency, making them popular in commercial roofing. Both materials provide waterproofing solutions but differ in composition and environmental performance.

Composition and Material Differences

PVC membranes are made from polyvinyl chloride combined with plasticizers and stabilizers, offering high flexibility and chemical resistance, whereas TPO membranes consist of a blend of polypropylene and ethylene-propylene rubber, resulting in superior UV and heat resistance. The plasticizers in PVC can lead to potential leaching over time, while TPO membranes are free from plasticizers, providing enhanced durability and environmental benefits. Material composition directly influences performance characteristics such as elasticity, resilience against weathering, and overall lifespan in roofing applications.

Installation Methods Compared

PVC membrane installation involves heat welding seams using hot-air guns, providing strong, waterproof joints ideal for complex roof shapes. TPO membrane employs hot-air welding or adhesive bonding, offering faster installation and flexibility for accommodating rooftop movements. Both membranes require specialized training, but TPO generally ensures quicker seam curing times and improved energy efficiency during installation.

Durability and Lifespan Analysis

PVC membrane roofing offers exceptional durability, featuring strong resistance to chemicals, punctures, and UV exposure, resulting in a typical lifespan of 20 to 30 years. TPO membranes, known for their flexibility and heat-reflective properties, generally last between 15 and 25 years but may be more susceptible to degradation under prolonged UV exposure. In environments demanding extended service life and chemical resistance, PVC membranes tend to outperform TPO in terms of longevity and maintenance requirements.

Energy Efficiency and Reflectivity

PVC membranes offer high energy efficiency due to their strong reflectivity, which reduces heat absorption and lowers cooling costs in buildings. TPO membranes also provide excellent reflectivity, often exceeding 85%, making them effective at reflecting UV rays and reducing urban heat island effects. Both materials contribute to sustainable building design by enhancing roof energy performance and improving overall thermal regulation.

Cost Comparison: PVC vs TPO

PVC membrane typically costs more upfront than TPO membrane due to its complex manufacturing process and higher material quality. TPO membrane offers a more budget-friendly option with lower installation expenses and reduced labor time, making it popular for cost-sensitive roofing projects. Long-term maintenance costs for PVC can be higher due to chemical sensitivity, whereas TPO membranes generally provide better UV resistance and durability, potentially lowering lifecycle expenses.

Environmental Impact and Sustainability

PVC membranes contain chlorine and release harmful dioxins during production and disposal, raising environmental and health concerns. TPO membranes are chlorine-free, fully recyclable, and have a lower carbon footprint, making them a more sustainable roofing option. Choosing TPO over PVC reduces toxic emissions and supports eco-friendly building practices.

Maintenance Requirements and Repairs

PVC membranes require regular cleaning to prevent dirt buildup and occasional inspections to detect seams or punctures, with repairs typically involving heat welding patches for long-lasting durability. TPO membranes demand minimal maintenance but should be routinely checked for membrane tears and seam integrity, as repairs often use adhesive bonding or heat welding depending on the damage. Both materials benefit from proactive maintenance to extend lifespan and optimize rooftop performance.

Suitability for Different Building Types

PVC membranes offer excellent chemical resistance and flexibility, making them suitable for commercial buildings with complex roof designs and industrial facilities exposed to harsh chemicals. TPO membranes provide superior UV resistance and energy efficiency, ideal for commercial and residential buildings in hot climates seeking sustainable roofing solutions. Both materials are compatible with flat and low-slope roofs, but choice depends on specific building requirements and environmental conditions.

Choosing the Right Membrane for Your Project

PVC membrane offers superior chemical resistance and durability, making it ideal for roofing projects exposed to harsh environmental conditions. TPO membrane provides excellent energy efficiency and UV resistance, often chosen for commercial buildings seeking sustainable and cost-effective solutions. Assessing project-specific factors such as climate, budget, and building codes ensures the selection of the most suitable membrane type.

PVC Membrane vs TPO Membrane Infographic

productdif.com

productdif.com