Open-cell spray foam offers superior air sealing and soundproofing benefits due to its low density and flexible structure, making it ideal for interior applications. Closed-cell spray foam provides higher R-values and acts as a moisture barrier, making it suitable for exterior walls and roofing where insulation and water resistance are critical. Choosing between the two depends on specific building requirements such as insulation performance, moisture control, and budget considerations.

Table of Comparison

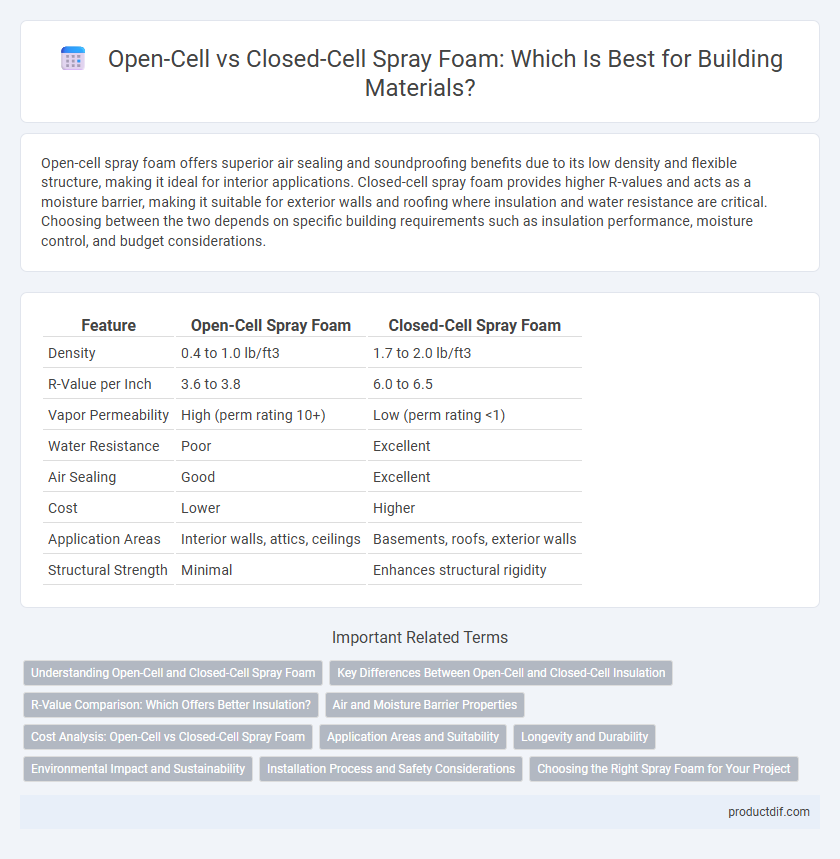

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| Density | 0.4 to 1.0 lb/ft3 | 1.7 to 2.0 lb/ft3 |

| R-Value per Inch | 3.6 to 3.8 | 6.0 to 6.5 |

| Vapor Permeability | High (perm rating 10+) | Low (perm rating <1) |

| Water Resistance | Poor | Excellent |

| Air Sealing | Good | Excellent |

| Cost | Lower | Higher |

| Application Areas | Interior walls, attics, ceilings | Basements, roofs, exterior walls |

| Structural Strength | Minimal | Enhances structural rigidity |

Understanding Open-Cell and Closed-Cell Spray Foam

Open-cell and closed-cell spray foam differ primarily in density and cellular structure, impacting insulation performance and moisture resistance. Open-cell foam, with a lower density and porous structure, offers excellent air sealing and soundproofing but absorbs water, making it less suitable for moisture-prone areas. Closed-cell foam, denser and with sealed cells, provides superior thermal insulation, structural strength, and water resistance, ideal for basements, roofs, and exterior walls.

Key Differences Between Open-Cell and Closed-Cell Insulation

Open-cell spray foam features a lower density and greater breathability, providing excellent soundproofing and flexibility, while closed-cell spray foam boasts higher density, superior rigidity, and a higher R-value per inch, making it better for structural support and moisture resistance. Open-cell foam expands more after application, filling irregular spaces effectively, whereas closed-cell foam limits air and vapor movement, enhancing energy efficiency and preventing water infiltration. The choice between these foams impacts insulation performance, durability, and suitability for specific building environments.

R-Value Comparison: Which Offers Better Insulation?

Closed-cell spray foam offers a higher R-value per inch, typically around 6 to 7, compared to open-cell foam's R-value of approximately 3.5 to 4, making it more effective for insulation in tight spaces. The dense structure of closed-cell foam also acts as a vapor barrier, enhancing its thermal resistance and moisture control capabilities. Open-cell foam, while providing some insulation, is less effective at preventing air and moisture infiltration, resulting in a lower overall R-value.

Air and Moisture Barrier Properties

Open-cell spray foam has a lower density, providing excellent air sealing but limited moisture resistance due to its permeable structure that allows water vapor to pass through. Closed-cell spray foam offers a high-density barrier that significantly reduces air infiltration and acts as a superior moisture barrier, preventing water absorption and enhancing structural durability. Installing closed-cell foam improves insulation efficiency by creating a robust seal against both air and moisture compared to the open-cell alternative.

Cost Analysis: Open-Cell vs Closed-Cell Spray Foam

Open-cell spray foam generally costs between $0.30 to $0.50 per board foot, making it a more budget-friendly option for insulation projects compared to closed-cell spray foam, which ranges from $1.00 to $1.50 per board foot due to its higher density and superior insulating properties. While closed-cell foam provides better structural support and moisture resistance, the upfront cost difference can be significant for large-scale applications. Evaluating long-term energy savings and durability benefits is essential when choosing between open-cell and closed-cell spray foam insulation.

Application Areas and Suitability

Open-cell spray foam excels in interior applications such as wall cavities, attics, and soundproofing due to its flexibility and vapor permeability, making it suitable for areas requiring breathability and moisture control. Closed-cell spray foam is ideal for exterior insulation, roofing, and below-grade applications because of its high density, superior structural support, and strong moisture barrier properties. Selecting between these foams depends on project requirements like insulation R-value, moisture resistance, and structural reinforcement needs.

Longevity and Durability

Closed-cell spray foam offers superior longevity and durability compared to open-cell spray foam due to its dense structure and higher R-value, providing enhanced resistance to moisture, pests, and structural damage. Open-cell foam, while flexible and effective for soundproofing, typically has a shorter lifespan and is more susceptible to water absorption and compression over time. Building projects requiring long-term insulation performance and structural reinforcement benefit most from the durability of closed-cell spray foam.

Environmental Impact and Sustainability

Closed-cell spray foam offers superior insulation with higher R-values and acts as a moisture barrier, but it relies on blowing agents with higher global warming potential, impacting environmental sustainability. Open-cell spray foam has lower density and allows vapor permeability, reducing material usage and energy consumption during production, which contributes to a lower carbon footprint. Selecting spray foam insulation requires balancing thermal efficiency with ecological impact, considering factors like greenhouse gas emissions and recyclability.

Installation Process and Safety Considerations

Open-cell spray foam is applied with a lower pressure and expands rapidly, requiring less protective gear but necessitates careful ventilation due to its off-gassing during curing. Closed-cell spray foam demands higher pressure application and specialized equipment, emphasizing stringent safety protocols like full respiratory protection to prevent exposure to isocyanates. Both materials require trained professionals for proper handling, ensuring optimal installation and minimizing health risks during the curing process.

Choosing the Right Spray Foam for Your Project

Choosing the right spray foam for your project depends on factors such as insulation needs, moisture control, and budget. Open-cell spray foam offers excellent soundproofing and air sealing with a lower R-value per inch, making it ideal for interior applications and areas with minimal moisture exposure. Closed-cell spray foam provides higher R-value, structural strength, and vapor barrier properties, making it suitable for exterior walls, roofs, and projects requiring moisture resistance and enhanced durability.

Open-cell spray foam vs Closed-cell spray foam Infographic

productdif.com

productdif.com