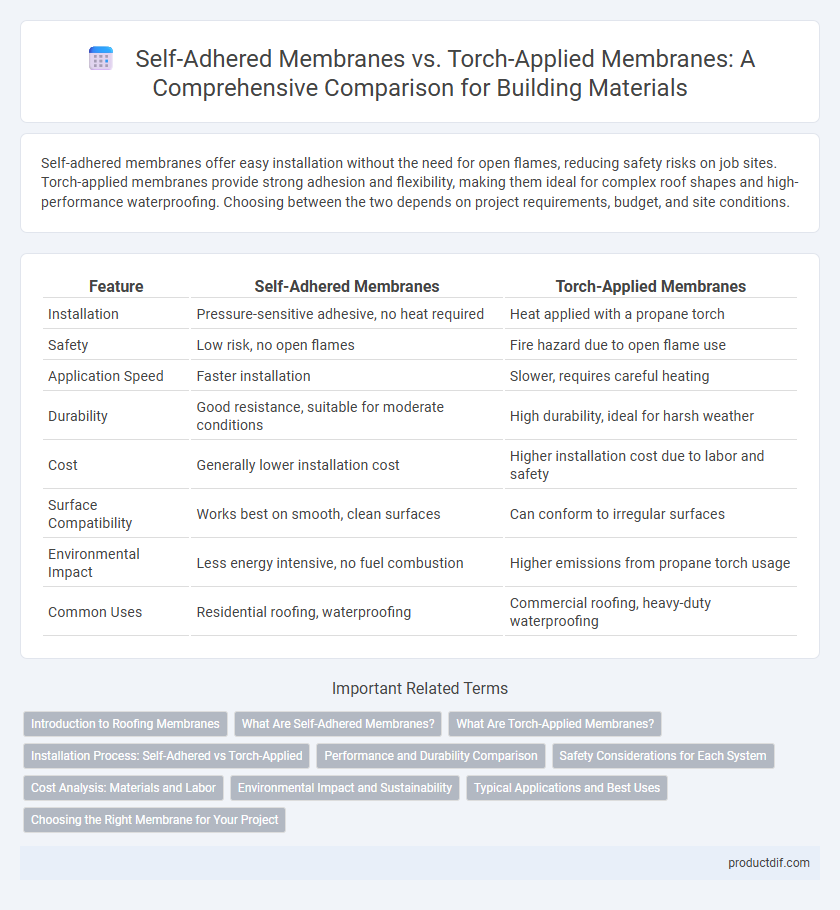

Self-adhered membranes offer easy installation without the need for open flames, reducing safety risks on job sites. Torch-applied membranes provide strong adhesion and flexibility, making them ideal for complex roof shapes and high-performance waterproofing. Choosing between the two depends on project requirements, budget, and site conditions.

Table of Comparison

| Feature | Self-Adhered Membranes | Torch-Applied Membranes |

|---|---|---|

| Installation | Pressure-sensitive adhesive, no heat required | Heat applied with a propane torch |

| Safety | Low risk, no open flames | Fire hazard due to open flame use |

| Application Speed | Faster installation | Slower, requires careful heating |

| Durability | Good resistance, suitable for moderate conditions | High durability, ideal for harsh weather |

| Cost | Generally lower installation cost | Higher installation cost due to labor and safety |

| Surface Compatibility | Works best on smooth, clean surfaces | Can conform to irregular surfaces |

| Environmental Impact | Less energy intensive, no fuel combustion | Higher emissions from propane torch usage |

| Common Uses | Residential roofing, waterproofing | Commercial roofing, heavy-duty waterproofing |

Introduction to Roofing Membranes

Self-adhered membranes offer a convenient, peel-and-stick installation process without the need for open flames, enhancing safety and reducing labor time. Torch-applied membranes require heating with a propane torch to bond the material, providing strong adhesion and durability for roofing applications. Both types deliver waterproofing solutions essential for protecting building structures, but the selection depends on project requirements such as safety, cost, and climate conditions.

What Are Self-Adhered Membranes?

Self-adhered membranes are roofing and waterproofing materials composed of rubberized asphalt or polymer modified bitumen with a peel-off backing that enables direct application to surfaces without the need for heat or additional adhesives. These membranes provide excellent adhesion, flexibility, and waterproofing, making them ideal for complex roof shapes and quick installations. Their ease of use and safety benefits distinguish them from torch-applied membranes, which require heat for application.

What Are Torch-Applied Membranes?

Torch-applied membranes are waterproofing materials used in roofing and foundation systems, installed by heating the membrane's underside with a torch to create a strong bond to the substrate. These membranes, typically made from modified bitumen or rubberized asphalt, offer high durability and excellent resistance to weather and mechanical damage. Torch application ensures a seamless, watertight barrier that enhances the longevity and performance of building envelopes.

Installation Process: Self-Adhered vs Torch-Applied

Self-adhered membranes offer a quicker, cleaner installation process by utilizing a peel-and-stick adhesive backing that eliminates the need for open flames or additional adhesives. Torch-applied membranes require skilled operators to carefully heat the membrane with a propane torch for proper adhesion, posing safety risks and potential fire hazards. Choosing between self-adhered and torch-applied membranes depends on project-specific factors such as site accessibility, installation speed, and safety considerations.

Performance and Durability Comparison

Self-adhered membranes offer superior ease of installation and consistent adhesion across various substrates, reducing the risk of installation errors compared to torch-applied membranes, which rely on heat and skilled labor for application. Performance-wise, torch-applied membranes often provide enhanced heat resistance and durability under extreme weather conditions, making them suitable for high-stress roofing environments. Long-term durability of torch-applied membranes is generally higher due to their robust, seamless bond, while self-adhered membranes excel in projects requiring faster turnaround and lower fire risk during installation.

Safety Considerations for Each System

Self-adhered membranes eliminate the risks of open flames, reducing fire hazards and improving on-site safety during installation. Torch-applied membranes require careful handling of propane torches, increasing the potential for burns and accidental fires, especially in confined or combustible environments. Proper training, adherence to safety protocols, and use of flame-retardant materials are critical when utilizing torch-applied systems to mitigate these hazards.

Cost Analysis: Materials and Labor

Self-adhered membranes typically offer lower labor costs due to easier installation that requires minimal equipment and reduced safety concerns, while torch-applied membranes demand skilled labor and specialized tools, driving up overall expenses. Material costs for self-adhered membranes are often higher, but the balance of reduced labor time and less risk of fire hazards can result in a more cost-effective solution. Evaluating total project costs should include the price of materials, labor hours, and potential safety compliance expenditures associated with each membrane type.

Environmental Impact and Sustainability

Self-adhered membranes reduce the environmental impact by eliminating open flames and lowering volatile organic compound (VOC) emissions compared to torch-applied membranes, which rely on gas torches during installation. These membranes often utilize recycled materials and contribute to improved indoor air quality through low chemical off-gassing, enhancing overall sustainability. Choosing self-adhered options aligns with green building certifications like LEED due to their energy-efficient application and reduced carbon footprint.

Typical Applications and Best Uses

Self-adhered membranes are ideal for residential roofing, green roofs, and underlayment in areas with low to moderate traffic due to their ease of installation and reduced fire risk. Torch-applied membranes excel in commercial roofing, flat roofs, and high-traffic areas requiring superior adhesion and durability under extreme weather conditions. Selecting between these membranes depends on project requirements such as substrate type, climate exposure, and application environment.

Choosing the Right Membrane for Your Project

Self-adhered membranes offer ease of installation and reduced fire risk, making them ideal for projects requiring quick application and enhanced safety. Torch-applied membranes provide superior adhesion and durability, especially in complex roof designs exposed to harsh weather conditions. Evaluating project-specific factors such as substrate type, climate, and installation environment ensures optimal membrane selection for long-lasting waterproofing performance.

Self-Adhered Membranes vs Torch-Applied Membranes Infographic

productdif.com

productdif.com