Rigid foam offers consistent insulation with high compressive strength, making it ideal for walls and roofs where structural support is crucial. Spray foam provides superior air sealing by expanding to fill gaps, effectively reducing thermal bridging and improving energy efficiency. Choosing between rigid foam and spray foam depends on project requirements such as moisture resistance, application ease, and budget constraints.

Table of Comparison

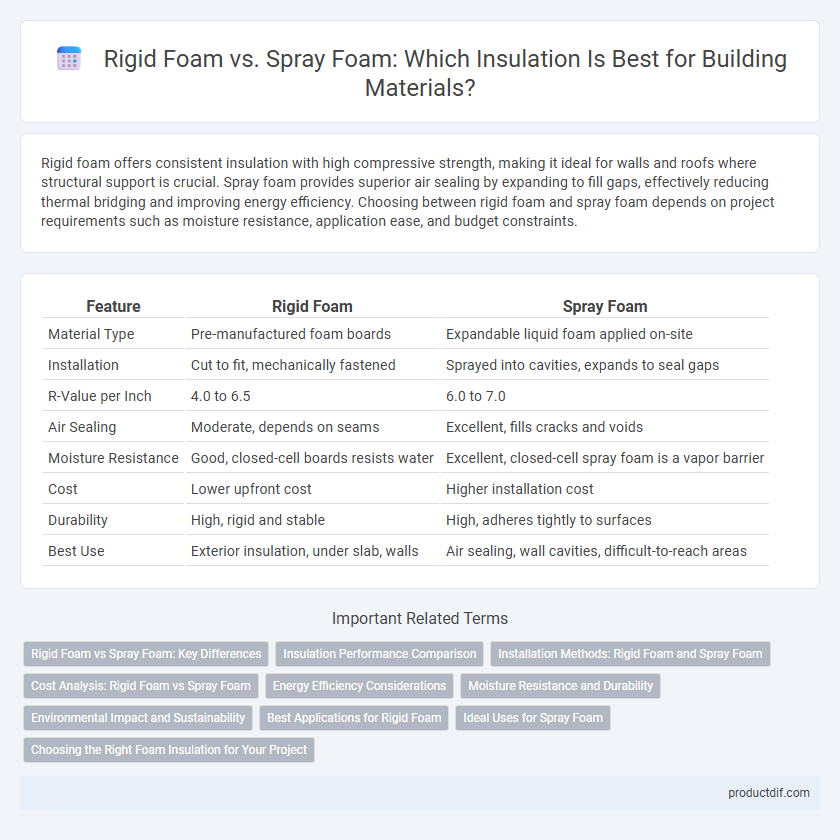

| Feature | Rigid Foam | Spray Foam |

|---|---|---|

| Material Type | Pre-manufactured foam boards | Expandable liquid foam applied on-site |

| Installation | Cut to fit, mechanically fastened | Sprayed into cavities, expands to seal gaps |

| R-Value per Inch | 4.0 to 6.5 | 6.0 to 7.0 |

| Air Sealing | Moderate, depends on seams | Excellent, fills cracks and voids |

| Moisture Resistance | Good, closed-cell boards resists water | Excellent, closed-cell spray foam is a vapor barrier |

| Cost | Lower upfront cost | Higher installation cost |

| Durability | High, rigid and stable | High, adheres tightly to surfaces |

| Best Use | Exterior insulation, under slab, walls | Air sealing, wall cavities, difficult-to-reach areas |

Rigid Foam vs Spray Foam: Key Differences

Rigid foam insulation, often made from polystyrene, polyisocyanurate, or polyurethane, offers a high R-value per inch and provides excellent structural support and moisture resistance for walls and roofs. Spray foam insulation, which expands upon application, creates an airtight seal that reduces air leakage and improves energy efficiency, making it effective in irregular or hard-to-reach spaces. While rigid foam is easier to install in large, flat areas, spray foam requires professional application but excels in sealing gaps and adapting to complex shapes.

Insulation Performance Comparison

Rigid foam insulation provides a high R-value per inch, typically between 5 and 6, offering excellent thermal resistance and moisture control for walls and roofs. Spray foam insulation, especially closed-cell varieties, achieves R-values around 6 to 7 per inch and expands to fill gaps, creating an airtight seal that reduces thermal bridging. Both materials improve energy efficiency, but spray foam excels in air sealing and versatility, while rigid foam is preferred for ease of installation and structural applications.

Installation Methods: Rigid Foam and Spray Foam

Rigid foam insulation consists of pre-manufactured panels that are cut to size and installed using adhesive or mechanical fasteners, providing a straightforward and clean application. Spray foam insulation is applied as a liquid that expands and hardens upon contact, allowing it to fill irregular spaces and create an airtight seal. Installation of rigid foam requires precise fitting and sealing of joints, while spray foam demands specialized equipment and professional application for optimal performance.

Cost Analysis: Rigid Foam vs Spray Foam

Rigid foam insulation typically costs between $0.25 and $0.50 per board foot, offering a lower upfront investment compared to spray foam, which ranges from $1.00 to $3.00 per board foot due to its application and material expenses. While rigid foam provides a cost-effective solution for exterior sheathing and crawl spaces, spray foam's superior air sealing and higher R-value per inch justify its premium in projects prioritizing energy efficiency and moisture control. Long-term savings with spray foam arise from reduced energy bills and enhanced building durability, offsetting its initial higher cost relative to rigid foam panels.

Energy Efficiency Considerations

Rigid foam insulation offers high thermal resistance with consistent R-values per inch, making it effective for reducing heat transfer in walls and roofs. Spray foam insulation expands to fill gaps and air leaks, providing superior air sealing and minimizing thermal bridging for enhanced energy efficiency. Selecting between rigid and spray foam depends on project requirements, budget, and desired insulation performance to optimize building energy savings.

Moisture Resistance and Durability

Rigid foam insulation offers superior moisture resistance due to its closed-cell structure, effectively preventing water absorption and reducing the risk of mold growth in building envelopes. Spray foam also provides excellent moisture resistance by creating an airtight seal, but it may be more susceptible to physical damage and require protective coatings to maintain long-term durability. Both insulation types enhance energy efficiency, yet rigid foam typically outperforms spray foam in maintaining structural integrity under prolonged exposure to moisture.

Environmental Impact and Sustainability

Rigid foam insulation typically has a lower global warming potential (GWP) due to its closed-cell structure and longer lifespan, while spray foam often uses blowing agents with higher GWP, impacting environmental sustainability. Rigid foam generates less off-gassing and is more easily recyclable, contributing to reduced environmental footprint compared to spray foam that may release volatile organic compounds (VOCs) during application. Choosing rigid foam supports sustainable building practices through durable thermal performance and lower environmental toxicity, whereas spray foam's expansion benefits must be weighed against its ecological trade-offs.

Best Applications for Rigid Foam

Rigid foam insulation is best suited for exterior wall sheathing, basement walls, and roof insulation due to its high compressive strength and moisture resistance. Its closed-cell structure provides excellent thermal resistance (R-value), making it ideal for continuous insulation in areas prone to water exposure or mechanical stress. Rigid foam panels are also widely used in insulating foundation walls and under slabs, where durability and long-term performance are critical.

Ideal Uses for Spray Foam

Spray foam insulation excels in sealing irregular or hard-to-reach spaces, providing exceptional air barrier properties and high R-value per inch that enhances a building's thermal efficiency. It is ideal for insulating walls, roofs, attics, and around HVAC ductwork where airtightness and moisture control are critical. Its expanding nature allows for effective filling of gaps and cracks, making it a preferred choice for energy-efficient and airtight construction projects.

Choosing the Right Foam Insulation for Your Project

Choosing the right foam insulation--rigid foam versus spray foam--depends on your project's specific needs, such as thermal resistance, moisture control, and ease of installation. Rigid foam panels offer high R-values per inch and are excellent for walls, roofs, and foundation insulation, providing consistent performance with minimal air leakage. Spray foam insulation expands to fill gaps and cracks, delivering superior air sealing and moisture barrier benefits, ideal for irregular spaces and improving overall energy efficiency.

Rigid Foam vs Spray Foam Infographic

productdif.com

productdif.com