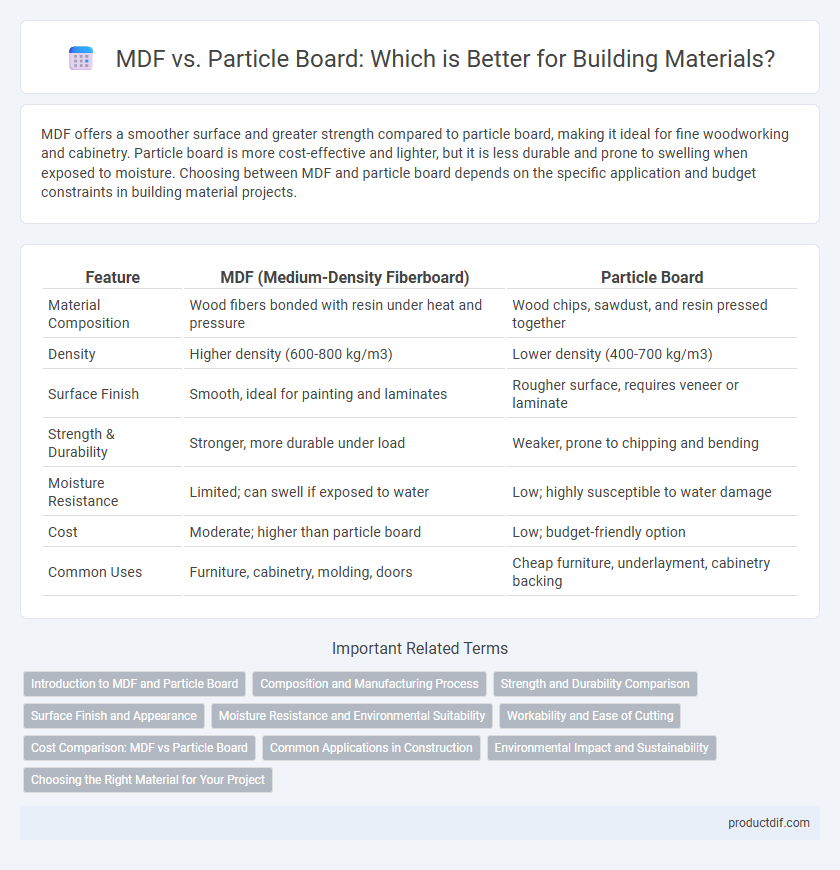

MDF offers a smoother surface and greater strength compared to particle board, making it ideal for fine woodworking and cabinetry. Particle board is more cost-effective and lighter, but it is less durable and prone to swelling when exposed to moisture. Choosing between MDF and particle board depends on the specific application and budget constraints in building material projects.

Table of Comparison

| Feature | MDF (Medium-Density Fiberboard) | Particle Board |

|---|---|---|

| Material Composition | Wood fibers bonded with resin under heat and pressure | Wood chips, sawdust, and resin pressed together |

| Density | Higher density (600-800 kg/m3) | Lower density (400-700 kg/m3) |

| Surface Finish | Smooth, ideal for painting and laminates | Rougher surface, requires veneer or laminate |

| Strength & Durability | Stronger, more durable under load | Weaker, prone to chipping and bending |

| Moisture Resistance | Limited; can swell if exposed to water | Low; highly susceptible to water damage |

| Cost | Moderate; higher than particle board | Low; budget-friendly option |

| Common Uses | Furniture, cabinetry, molding, doors | Cheap furniture, underlayment, cabinetry backing |

Introduction to MDF and Particle Board

MDF (Medium Density Fiberboard) is engineered from wood fibers bonded with resin under high pressure, offering a smooth, consistent surface ideal for painting and finishing. Particle board consists of wood chips, shavings, and sawdust mixed with adhesive, resulting in a lightweight, cost-effective panel commonly used for furniture and cabinetry. Both materials serve as economical alternatives to solid wood, with MDF providing greater density and strength compared to particle board.

Composition and Manufacturing Process

Medium Density Fiberboard (MDF) is composed of fine wood fibers combined with resin and wax, then compressed under high temperature and pressure to create a smooth, dense panel. Particle board is made from larger wood chips and particles bonded with synthetic resin, pressed into sheets, resulting in a coarser texture and lower density than MDF. The manufacturing process of MDF involves refining wood fibers for uniform consistency, whereas particle board production uses wood flakes and chips that require less processing and produce a more porous material.

Strength and Durability Comparison

MDF (Medium Density Fiberboard) offers superior strength and durability compared to particle board due to its denser and more uniform composition, making it less prone to warping and cracking under stress. Particle board, while more affordable, is more susceptible to moisture damage and has lower load-bearing capacity, leading to faster deterioration in demanding applications. For long-term structural integrity, MDF is the preferred choice in furniture and cabinetry where strength and durability are critical.

Surface Finish and Appearance

MDF offers a smooth, consistent surface ideal for paint and veneer applications, providing a refined and uniform appearance without visible grain or knots. Particle board typically has a rougher texture with noticeable wood chips and a less polished finish, making it less suitable for high-quality surface treatments. Surface finish quality directly influences the final aesthetic, with MDF preferred in projects requiring sleek and elegant design elements.

Moisture Resistance and Environmental Suitability

Medium Density Fiberboard (MDF) offers better moisture resistance compared to particle board due to its denser and more uniform composition, making it less prone to swelling and warping in humid environments. Particle board tends to absorb moisture more readily, leading to structural weakness and reduced durability in bathrooms or kitchens without proper sealing. MDF's eco-friendliness is enhanced by its use of recycled wood fibers and adhesives with low volatile organic compounds (VOCs), whereas particle board often involves formaldehyde-based resins that may pose greater environmental and health concerns.

Workability and Ease of Cutting

MDF offers superior workability and ease of cutting compared to particle board due to its dense and uniform composition, which reduces splintering and allows for precise shaping. Particle board, composed of compressed wood particles and resin, tends to chip and produce rough edges when cut, requiring more careful handling and specialized blades. High-quality carbide-tipped saw blades and slower cutting speeds improve results for both materials but MDF remains the preferred choice for detailed woodworking projects.

Cost Comparison: MDF vs Particle Board

MDF generally costs more than particle board due to its finer wood fibers and denser composition, which enhance durability and finish quality. Particle board is more affordable, making it suitable for budget-conscious projects with less emphasis on strength and surface smoothness. Cost differences should be balanced with intended use, as MDF's higher price often corresponds to better performance in cabinetry and furniture.

Common Applications in Construction

MDF (Medium Density Fiberboard) is commonly used for cabinetry, furniture, and decorative paneling due to its smooth surface and ease of finishing. Particle board is often utilized in subflooring, underlayment, and inexpensive furniture where moisture resistance and durability are less critical. Both materials serve essential roles in construction, with MDF favored for aesthetic applications and particle board chosen for cost-effective, structural purposes.

Environmental Impact and Sustainability

MDF (Medium Density Fiberboard) generally has a lower environmental impact than particle board due to its higher density and better utilization of wood fibers, resulting in less waste during production. Both materials are often made from recycled wood scraps, but MDF typically contains fewer formaldehyde resins, reducing the release of harmful volatile organic compounds (VOCs) into the environment. Sustainable sourcing of raw materials and advances in eco-friendly adhesives are critical factors improving the overall sustainability profiles of both MDF and particle board in the building industry.

Choosing the Right Material for Your Project

MDF offers a smooth surface ideal for detailed painting and intricate designs, making it perfect for cabinetry and furniture requiring a refined finish. Particle board, while more budget-friendly, is less durable and prone to moisture damage, best suited for temporary or low-stress applications such as shelving or underlayment. Assess project requirements like moisture exposure, load-bearing needs, and finish quality to determine whether MDF's durability and versatility or particle board's cost-effectiveness aligns better with your construction goals.

MDF vs Particle Board Infographic

productdif.com

productdif.com