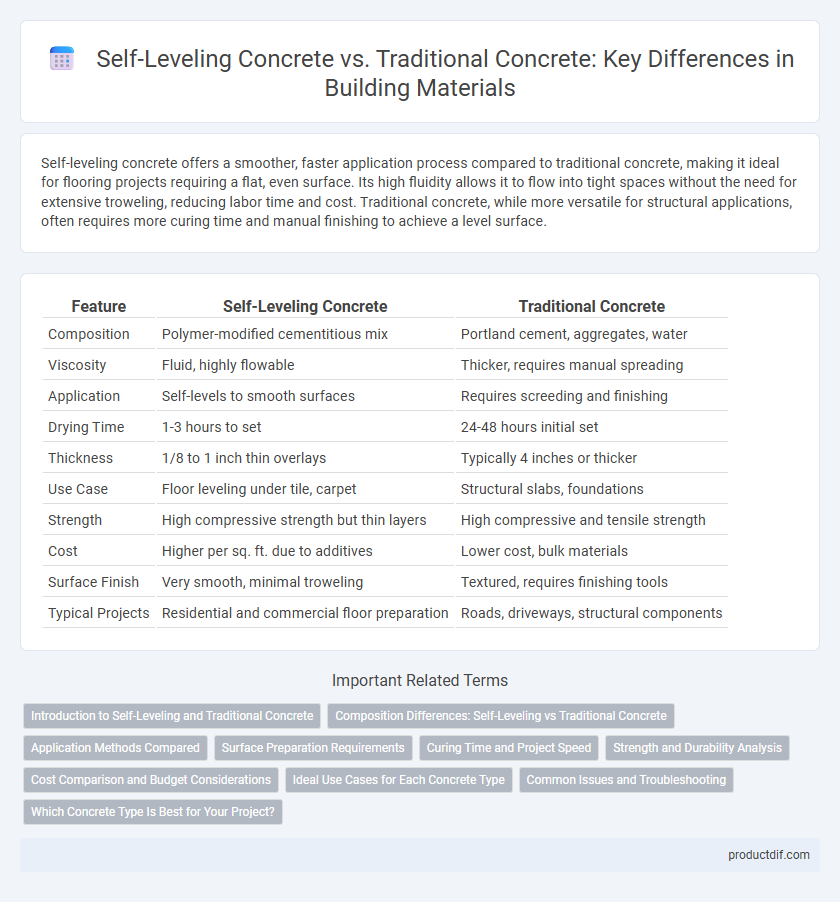

Self-leveling concrete offers a smoother, faster application process compared to traditional concrete, making it ideal for flooring projects requiring a flat, even surface. Its high fluidity allows it to flow into tight spaces without the need for extensive troweling, reducing labor time and cost. Traditional concrete, while more versatile for structural applications, often requires more curing time and manual finishing to achieve a level surface.

Table of Comparison

| Feature | Self-Leveling Concrete | Traditional Concrete |

|---|---|---|

| Composition | Polymer-modified cementitious mix | Portland cement, aggregates, water |

| Viscosity | Fluid, highly flowable | Thicker, requires manual spreading |

| Application | Self-levels to smooth surfaces | Requires screeding and finishing |

| Drying Time | 1-3 hours to set | 24-48 hours initial set |

| Thickness | 1/8 to 1 inch thin overlays | Typically 4 inches or thicker |

| Use Case | Floor leveling under tile, carpet | Structural slabs, foundations |

| Strength | High compressive strength but thin layers | High compressive and tensile strength |

| Cost | Higher per sq. ft. due to additives | Lower cost, bulk materials |

| Surface Finish | Very smooth, minimal troweling | Textured, requires finishing tools |

| Typical Projects | Residential and commercial floor preparation | Roads, driveways, structural components |

Introduction to Self-Leveling and Traditional Concrete

Self-leveling concrete is a polymer-modified, high-flow mixture designed to create smooth, flat surfaces with minimal labor, ideal for indoor flooring and renovation projects. Traditional concrete, composed of cement, water, sand, and aggregate, offers high compressive strength and durability but requires extensive finishing and curing efforts. The rapid setting and self-leveling properties of self-leveling concrete significantly reduce installation time compared to traditional concrete mixes.

Composition Differences: Self-Leveling vs Traditional Concrete

Self-leveling concrete contains a higher proportion of cement, fine aggregates, and chemical admixtures such as polymers and viscosity modifiers, which enhance flowability and reduce water content compared to traditional concrete. Traditional concrete incorporates larger aggregates and uses more water to achieve workability, resulting in a coarser and less fluid mixture. The advanced composition of self-leveling concrete enables it to spread and level itself without mechanical assistance, making it ideal for smooth flooring applications.

Application Methods Compared

Self-leveling concrete requires a simplified application method involving pumping or pouring with minimal labor for spreading due to its fluid consistency, enabling faster project completion. Traditional concrete demands more intensive manual labor, including mixing, placing, and extensive screeding and finishing to ensure level surfaces. The ease of use with self-leveling concrete reduces installation time and operator skill requirements compared to traditional concrete's complex process.

Surface Preparation Requirements

Self-leveling concrete requires minimal surface preparation, often only cleaning and priming to ensure proper adhesion, making it ideal for quick renovation projects. Traditional concrete demands extensive surface preparation, including thorough compaction, grading, and sometimes the installation of a vapor barrier to prevent moisture issues. These differences significantly impact project timelines and labor costs in construction and flooring applications.

Curing Time and Project Speed

Self-leveling concrete typically cures within 24 to 48 hours, significantly faster than traditional concrete, which can take up to 28 days for full curing. This rapid curing time accelerates project speed, allowing for quicker installation of flooring or finishing layers. Faster turnaround reduces labor costs and downtime, making self-leveling concrete ideal for time-sensitive construction projects.

Strength and Durability Analysis

Self-leveling concrete typically exhibits higher compressive strength and enhanced durability compared to traditional concrete due to its refined mix design and superior flow characteristics. The polymer-modified additives in self-leveling concrete improve crack resistance and reduce shrinkage, leading to longer-lasting surfaces under heavy loads. Traditional concrete, while strong, often requires additional finishing and curing techniques to achieve comparable durability levels in high-stress environments.

Cost Comparison and Budget Considerations

Self-leveling concrete often incurs higher upfront costs compared to traditional concrete due to specialized additives and enhanced flow properties, impacting initial budget allocations. Traditional concrete remains more cost-effective for large-scale, non-complex projects but may require additional labor for surface finishing, increasing overall expenses. Budget considerations should factor in both material costs and labor efficiency, as self-leveling concrete can reduce labor time and long-term maintenance costs, offering potential savings in lifecycle expenditures.

Ideal Use Cases for Each Concrete Type

Self-leveling concrete is ideal for interior flooring projects requiring a smooth, flat surface with minimal labor, such as underlayment for tiles or hardwood floors in residential and commercial buildings. Traditional concrete excels in structural applications, including foundations, driveways, and outdoor pavements, where high strength and durability are crucial. Selecting the appropriate concrete depends on project requirements like surface finish, load-bearing capacity, and installation speed.

Common Issues and Troubleshooting

Self-leveling concrete often faces issues such as shrinkage cracks and improper curing, which can be mitigated by precise water-to-mix ratios and controlled drying environments. Traditional concrete commonly encounters problems like surface scaling and uneven settling, typically resolved through adequate curing times and proper subgrade preparation. Both materials require regular monitoring for moisture levels and temperature fluctuations to ensure optimal strength and durability.

Which Concrete Type Is Best for Your Project?

Self-leveling concrete offers superior ease of application and faster curing times, making it ideal for projects requiring smooth, flat surfaces such as flooring overlays and repairs. Traditional concrete provides greater structural strength and durability for foundational work and heavy-load applications, suitable for driveways, sidewalks, and structural slabs. Choosing the best concrete type depends on the project's load demands, surface finish requirements, and installation timeline.

Self-Leveling Concrete vs Traditional Concrete Infographic

productdif.com

productdif.com