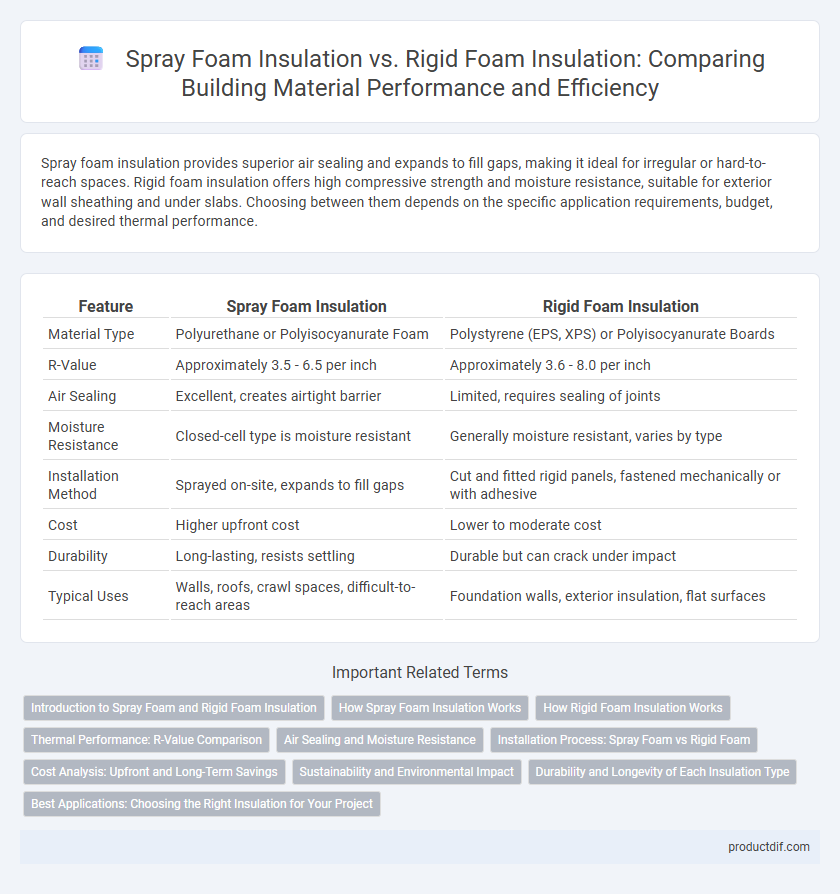

Spray foam insulation provides superior air sealing and expands to fill gaps, making it ideal for irregular or hard-to-reach spaces. Rigid foam insulation offers high compressive strength and moisture resistance, suitable for exterior wall sheathing and under slabs. Choosing between them depends on the specific application requirements, budget, and desired thermal performance.

Table of Comparison

| Feature | Spray Foam Insulation | Rigid Foam Insulation |

|---|---|---|

| Material Type | Polyurethane or Polyisocyanurate Foam | Polystyrene (EPS, XPS) or Polyisocyanurate Boards |

| R-Value | Approximately 3.5 - 6.5 per inch | Approximately 3.6 - 8.0 per inch |

| Air Sealing | Excellent, creates airtight barrier | Limited, requires sealing of joints |

| Moisture Resistance | Closed-cell type is moisture resistant | Generally moisture resistant, varies by type |

| Installation Method | Sprayed on-site, expands to fill gaps | Cut and fitted rigid panels, fastened mechanically or with adhesive |

| Cost | Higher upfront cost | Lower to moderate cost |

| Durability | Long-lasting, resists settling | Durable but can crack under impact |

| Typical Uses | Walls, roofs, crawl spaces, difficult-to-reach areas | Foundation walls, exterior insulation, flat surfaces |

Introduction to Spray Foam and Rigid Foam Insulation

Spray foam insulation offers superior air sealing and high R-value per inch, making it ideal for complex or irregular spaces where gaps and cracks need to be fully sealed. Rigid foam insulation, available in polystyrene, polyisocyanurate, and polyurethane boards, provides excellent thermal resistance and moisture control for walls, roofs, and foundations. Both materials improve energy efficiency, but spray foam excels in expanding to fill cavities, while rigid foam delivers consistent insulation thickness and structural support.

How Spray Foam Insulation Works

Spray foam insulation works by expanding upon application, filling gaps and hard-to-reach areas to create an airtight seal that significantly reduces heat transfer and air leakage. It adheres tightly to surfaces, providing superior thermal resistance compared to rigid foam boards, which are pre-cut panels offering standard insulation values. This expanding capability makes spray foam ideal for irregular spaces, improving overall energy efficiency in buildings.

How Rigid Foam Insulation Works

Rigid foam insulation works by creating a dense, closed-cell structure that resists heat flow and moisture absorption, providing superior thermal resistance compared to many other insulation types. Its solid panels are typically made from materials like polyisocyanurate, extruded polystyrene (XPS), or expanded polystyrene (EPS), offering durability and structural support in walls, roofs, and foundations. This insulation type effectively reduces air leakage and thermal bridging, enhancing energy efficiency and long-term moisture protection in building envelopes.

Thermal Performance: R-Value Comparison

Spray foam insulation typically offers an R-value between 3.5 to 6.5 per inch, providing superior air sealing and continuous insulation. Rigid foam insulation, such as polyisocyanurate or extruded polystyrene, ranges from 3.8 to 6.5 R-value per inch but lacks the air-sealing properties of spray foam. The enhanced thermal performance of spray foam insulation results in better energy efficiency and reduced heat transfer in building envelopes.

Air Sealing and Moisture Resistance

Spray foam insulation excels in air sealing by expanding to fill gaps and cracks, creating a continuous barrier that minimizes air leakage and enhances energy efficiency. Rigid foam insulation provides strong moisture resistance due to its dense, closed-cell structure, preventing water absorption and reducing the risk of mold growth. Combining spray foam for air sealing with rigid foam for moisture control delivers optimal performance in building envelope protection.

Installation Process: Spray Foam vs Rigid Foam

Spray foam insulation requires professional equipment for application, as it is sprayed directly onto surfaces, expanding to fill gaps and creating an airtight seal, which can be more time-efficient but demands expert handling. Rigid foam insulation involves cutting large panels to size and fastening them manually on walls or roofs, allowing straightforward DIY installation but potentially requiring additional sealing to prevent air leaks. The choice between spray foam and rigid foam installation depends on project complexity, budget, and desired energy efficiency outcomes.

Cost Analysis: Upfront and Long-Term Savings

Spray foam insulation typically has higher upfront costs compared to rigid foam insulation due to specialized application processes and materials but offers superior air sealing and higher R-values per inch, which can lead to significant long-term energy savings. Rigid foam insulation provides a more affordable initial investment and ease of installation, yet may require supplementary sealing to achieve comparable energy efficiency, potentially increasing maintenance expenses over time. Evaluating the balance between installation costs, energy savings, and durability is essential for selecting the most cost-effective insulation solution for specific building projects.

Sustainability and Environmental Impact

Spray foam insulation offers superior air sealing capabilities, reducing energy consumption and lowering carbon footprints in buildings compared to rigid foam insulation. However, rigid foam insulation typically has a higher recycled content and is easier to recycle at end-of-life, contributing to a more circular building material lifecycle. Both materials require careful consideration of their chemical components and manufacturing processes to minimize environmental impact and promote long-term sustainability in construction projects.

Durability and Longevity of Each Insulation Type

Spray foam insulation offers superior durability by expanding to fill gaps and creating an airtight seal that resists moisture and mold growth, extending its lifespan beyond 30 years. Rigid foam insulation, composed of expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate, maintains structural integrity and moisture resistance but may degrade faster under prolonged UV exposure or physical damage, typically lasting 20 to 25 years. Selecting insulation depends on environmental factors and installation quality, which critically impact the longevity and performance of both spray and rigid foam materials.

Best Applications: Choosing the Right Insulation for Your Project

Spray foam insulation excels in sealing irregular cavities and providing superior air and moisture barriers, ideal for attics, crawl spaces, and around HVAC systems. Rigid foam insulation offers high compressive strength and consistent R-value, making it suitable for exterior walls, foundation walls, and under slab applications. Selecting the right insulation depends on project-specific factors such as thermal performance requirements, space constraints, and exposure to moisture.

Spray foam insulation vs Rigid foam insulation Infographic

productdif.com

productdif.com