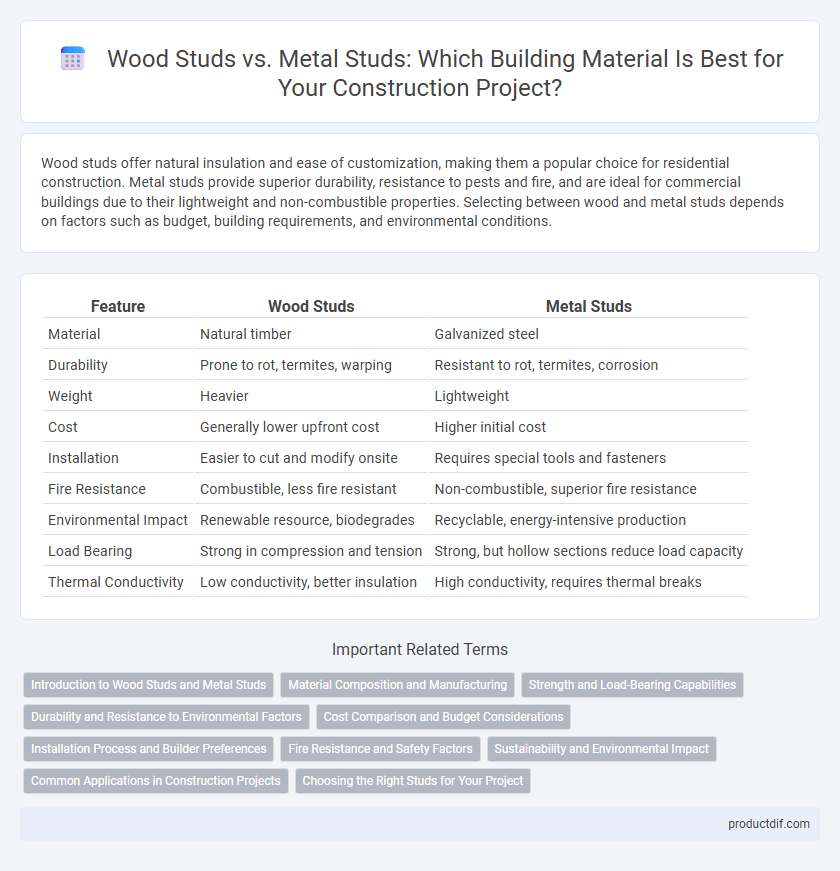

Wood studs offer natural insulation and ease of customization, making them a popular choice for residential construction. Metal studs provide superior durability, resistance to pests and fire, and are ideal for commercial buildings due to their lightweight and non-combustible properties. Selecting between wood and metal studs depends on factors such as budget, building requirements, and environmental conditions.

Table of Comparison

| Feature | Wood Studs | Metal Studs |

|---|---|---|

| Material | Natural timber | Galvanized steel |

| Durability | Prone to rot, termites, warping | Resistant to rot, termites, corrosion |

| Weight | Heavier | Lightweight |

| Cost | Generally lower upfront cost | Higher initial cost |

| Installation | Easier to cut and modify onsite | Requires special tools and fasteners |

| Fire Resistance | Combustible, less fire resistant | Non-combustible, superior fire resistance |

| Environmental Impact | Renewable resource, biodegrades | Recyclable, energy-intensive production |

| Load Bearing | Strong in compression and tension | Strong, but hollow sections reduce load capacity |

| Thermal Conductivity | Low conductivity, better insulation | High conductivity, requires thermal breaks |

Introduction to Wood Studs and Metal Studs

Wood studs are traditional framing materials made from lumber, widely used for their natural insulation properties and ease of handling in residential construction. Metal studs, composed of galvanized steel, offer durability, resistance to termites and fire, and are commonly preferred in commercial and high-moisture applications. Choosing between wood and metal studs depends on factors such as structural requirements, budget, environmental conditions, and project scale.

Material Composition and Manufacturing

Wood studs are primarily composed of natural timber, typically softwoods like pine or fir, and are manufactured through processes involving sawing, drying, and sometimes kiln-treatment to enhance durability and resistance to pests. Metal studs consist mainly of galvanized steel, formed by roll-forming thin sheets of steel into C-shaped or U-shaped profiles, which ensures lightweight strength and corrosion resistance. The manufacturing of metal studs involves precise sheet metal fabrication techniques, offering consistent dimensions and fire resistance compared to the variability found in natural wood materials.

Strength and Load-Bearing Capabilities

Wood studs offer excellent load-bearing capabilities for residential construction due to their natural strength and flexibility, making them ideal for walls supporting moderate to heavy loads. Metal studs, typically made from cold-formed steel, provide superior strength-to-weight ratios and resist warping, making them suitable for commercial buildings and structures requiring greater durability under heavy loads. When evaluating strength and load-bearing performance, wood studs excel in traditional framing applications, while metal studs offer enhanced consistency and resilience in high-stress or moisture-prone environments.

Durability and Resistance to Environmental Factors

Wood studs offer strong natural insulation and resist minor impacts but are prone to rot, mold, and termite damage in humid or wet environments. Metal studs provide superior durability against fire, moisture, and pests, maintaining structural integrity over time without warping or splitting. Their corrosion resistance and non-combustible properties make metal studs ideal for areas with high environmental stress or strict building codes.

Cost Comparison and Budget Considerations

Wood studs generally cost less upfront than metal studs, making them a preferred choice for budget-sensitive construction projects. Metal studs, while initially more expensive, offer long-term savings through durability, resistance to pests, and reduced maintenance costs. Budget considerations should factor in material price, installation labor, and lifecycle expenses to determine the most cost-effective option.

Installation Process and Builder Preferences

Wood studs offer faster installation due to their lightweight nature and ease of cutting with standard tools, making them popular in residential construction. Metal studs require specialized tools for cutting and fastening but provide consistent straightness and are favored in commercial projects for fire resistance and durability. Builder preferences often hinge on job type and budget, with wood preferred for traditional framing and metal chosen for non-combustible applications.

Fire Resistance and Safety Factors

Metal studs offer superior fire resistance compared to wood studs due to their non-combustible nature, significantly reducing the risk of structural fire damage. Wood studs, while traditional, are combustible and can contribute to fire spread, necessitating additional treatment or protective measures for enhanced safety. Steel framing also maintains structural integrity longer in high temperatures, providing critical safety advantages in fire-prone construction environments.

Sustainability and Environmental Impact

Wood studs offer renewable sourcing and carbon sequestration benefits, making them a sustainable choice with lower embodied energy compared to metal studs. Metal studs, typically made from steel, provide recyclability and durability but require high energy for production and contribute more to greenhouse gas emissions. Choosing wood studs reduces environmental impact through biodegradability and renewable growth cycles, while metal studs excel in recyclability but pose challenges due to resource extraction and manufacturing energy intensity.

Common Applications in Construction Projects

Wood studs are commonly used in residential construction for framing walls, ceilings, and partitions due to their affordability, ease of handling, and natural insulation properties. Metal studs dominate commercial building projects, including office spaces and high-rise structures, because of their durability, resistance to fire and pests, and consistent strength. Both wood and metal studs serve critical roles in framing but are selected based on project requirements such as budget, structural needs, and environmental conditions.

Choosing the Right Studs for Your Project

Wood studs provide excellent thermal insulation and are easier to cut and fasten, making them ideal for residential construction projects with moderate budgets. Metal studs offer superior fire resistance, durability, and resistance to pests and moisture, suitable for commercial buildings or areas with high humidity. Selecting the right studs depends on factors such as project location, budget constraints, required load-bearing capacity, and environmental exposure.

Wood Studs vs Metal Studs Infographic

productdif.com

productdif.com