Lift-slab construction involves casting concrete slabs on the ground and then lifting them into place, which accelerates the building process and reduces formwork costs. Tilt-up construction casts panels horizontally on-site and then tilts them vertically to form walls, offering greater flexibility in architectural design and heavier load capacity. Both methods improve efficiency and quality but differ in installation techniques and structural applications, making material selection critical for durability and performance.

Table of Comparison

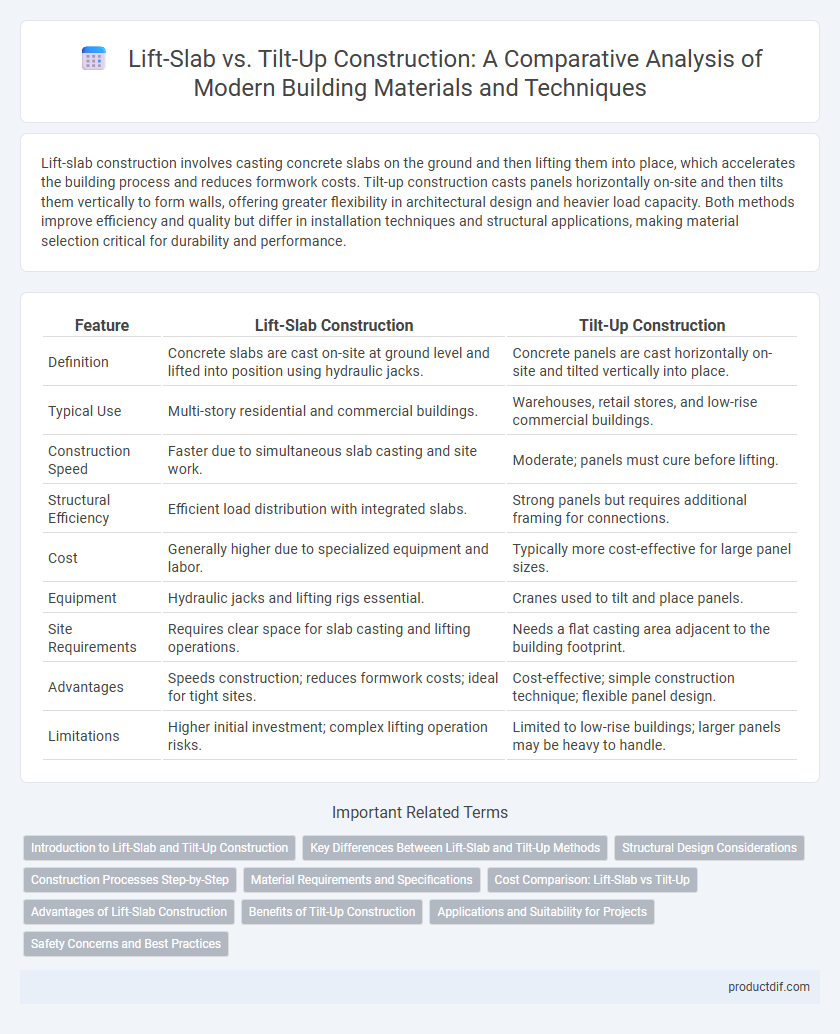

| Feature | Lift-Slab Construction | Tilt-Up Construction |

|---|---|---|

| Definition | Concrete slabs are cast on-site at ground level and lifted into position using hydraulic jacks. | Concrete panels are cast horizontally on-site and tilted vertically into place. |

| Typical Use | Multi-story residential and commercial buildings. | Warehouses, retail stores, and low-rise commercial buildings. |

| Construction Speed | Faster due to simultaneous slab casting and site work. | Moderate; panels must cure before lifting. |

| Structural Efficiency | Efficient load distribution with integrated slabs. | Strong panels but requires additional framing for connections. |

| Cost | Generally higher due to specialized equipment and labor. | Typically more cost-effective for large panel sizes. |

| Equipment | Hydraulic jacks and lifting rigs essential. | Cranes used to tilt and place panels. |

| Site Requirements | Requires clear space for slab casting and lifting operations. | Needs a flat casting area adjacent to the building footprint. |

| Advantages | Speeds construction; reduces formwork costs; ideal for tight sites. | Cost-effective; simple construction technique; flexible panel design. |

| Limitations | Higher initial investment; complex lifting operation risks. | Limited to low-rise buildings; larger panels may be heavy to handle. |

Introduction to Lift-Slab and Tilt-Up Construction

Lift-slab construction involves casting concrete slabs on the ground and then lifting them into position using hydraulic jacks, allowing for faster assembly and reduced formwork costs. Tilt-up construction consists of casting concrete panels horizontally on-site and then tilting them vertically into place, offering efficiency in material usage and design flexibility. Both methods provide innovative alternatives to traditional building techniques, maximizing speed and structural integrity in commercial and residential projects.

Key Differences Between Lift-Slab and Tilt-Up Methods

Lift-slab construction involves casting concrete slabs horizontally on the ground and then lifting them into place using hydraulic jacks, allowing for faster vertical assembly and reduced formwork costs. Tilt-up construction casts wall panels on-site horizontally and tilts them up into position, offering greater flexibility in wall thickness and architectural finishes. Key differences include the lifting mechanism, with lift-slab focusing on floor slabs and tilt-up concentrating on wall panels, influencing project timeline, cost-effectiveness, and design adaptability.

Structural Design Considerations

Lift-slab construction enables the repetitive use of uniform slab designs, optimizing load distribution and reducing formwork complexity, while tilt-up construction requires careful bracing and reinforcement to resist lateral forces during panel erection. Structural design considerations for lift-slab demand precise alignment and connection detailing to ensure continuity and stability between lifted slabs and columns. Tilt-up designs focus on panel thickness, joint placement, and anchorage systems to accommodate wind loads and prevent cracking during handling and post-installation.

Construction Processes Step-by-Step

Lift-slab construction involves casting concrete slabs on the ground, then lifting them into place with hydraulic jacks, reducing formwork and scaffolding needs. Tilt-up construction requires casting wall panels horizontally on-site and then tilting them vertically using cranes, allowing for rapid assembly and reduced crane time compared to traditional methods. Both methods optimize efficiency but differ in sequencing: lift-slab emphasizes vertical lifting of floor slabs, while tilt-up centers on erecting precast wall panels.

Material Requirements and Specifications

Lift-slab construction primarily requires lightweight concrete slabs with high early strength to support the lifting process, often incorporating steel cables or jacks for vertical movement. Tilt-up construction demands heavier, thicker concrete panels reinforced with steel rebar to withstand the tilting and setting operations on-site. Both methods necessitate precise material specifications to ensure structural integrity, with lift-slab focusing on slab weight and strength, and tilt-up emphasizing panel durability and reinforcement.

Cost Comparison: Lift-Slab vs Tilt-Up

Lift-slab construction typically incurs higher initial costs due to specialized equipment and engineering requirements, whereas tilt-up construction offers cost savings through faster on-site assembly and reduced labor expenses. Material costs for tilt-up panels are often lower as they are cast horizontally on-site, minimizing the need for extensive formwork and scaffolding present in lift-slab projects. Overall, tilt-up construction is generally more economical for large-scale commercial buildings, while lift-slab may justify higher upfront costs in projects with specific architectural or structural demands.

Advantages of Lift-Slab Construction

Lift-slab construction offers significant advantages such as faster project completion due to simultaneous floor casting and quick slab lifting, which reduces overall labor costs and site congestion. This method enhances structural integrity by minimizing the number of joints compared to tilt-up construction, leading to improved durability and reduced maintenance. Safety is also improved because much of the work is performed at ground level, lowering risks associated with working at height.

Benefits of Tilt-Up Construction

Tilt-up construction offers significant cost savings by reducing the need for extensive formwork and scaffolding, making it an efficient choice for large commercial buildings. Its faster construction timeline allows for rapid project completion, minimizing labor expenses and accelerating occupancy. The method's flexibility supports diverse architectural designs while providing durable, high-quality concrete panels that enhance structural integrity and thermal performance.

Applications and Suitability for Projects

Lift-slab construction is ideal for multi-story buildings requiring rapid vertical assembly, such as residential apartments and hospitals, due to its efficient slab lifting technique. Tilt-up construction suits low- to mid-rise commercial and industrial projects, offering cost-effective site-cast concrete panels with quick installation. Both methods optimize labor and material use but differ in structural complexity and project scale suitability.

Safety Concerns and Best Practices

Lift-slab construction involves raising precast concrete slabs into position using hydraulic jacks, requiring rigorous monitoring of weight distribution to prevent slab collapse, while tilt-up construction entails casting concrete panels on-site and tilting them into place, demanding strict adherence to crane operation protocols to avoid accidents. Both methods pose significant safety risks such as falling panels and structural instability, necessitating comprehensive worker training, use of personal protective equipment, and adherence to OSHA guidelines for rigging and lifting. Implementing controlled lifting sequences, detailed site inspections, and real-time communication among crew members enhances safety during the installation phase of both lift-slab and tilt-up construction projects.

Lift-slab vs Tilt-up Construction Infographic

productdif.com

productdif.com