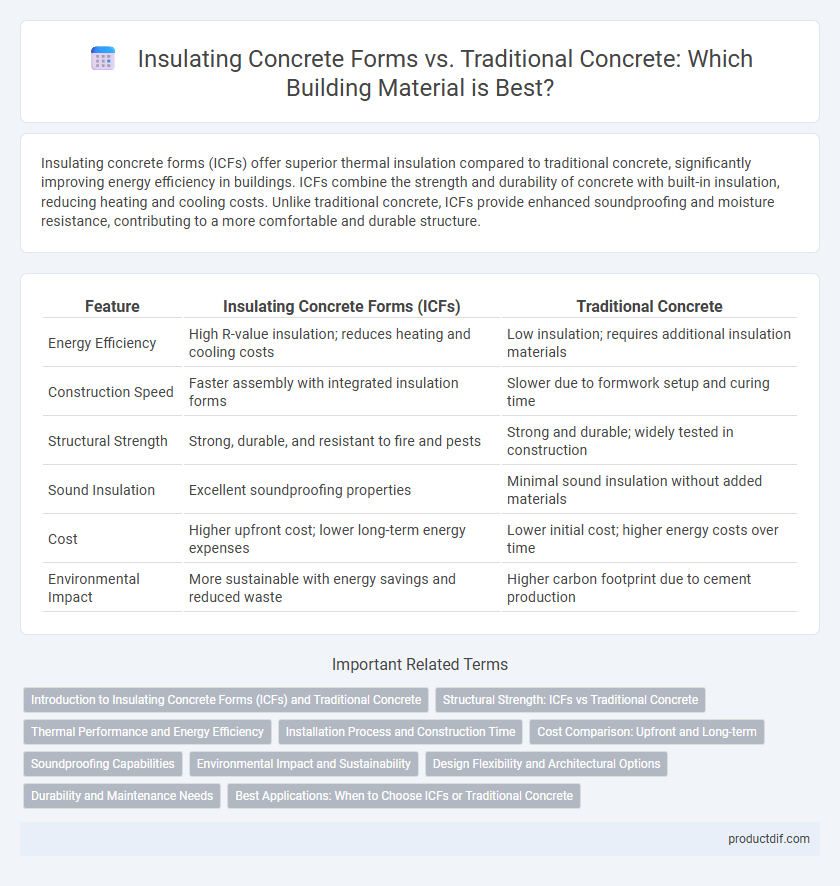

Insulating concrete forms (ICFs) offer superior thermal insulation compared to traditional concrete, significantly improving energy efficiency in buildings. ICFs combine the strength and durability of concrete with built-in insulation, reducing heating and cooling costs. Unlike traditional concrete, ICFs provide enhanced soundproofing and moisture resistance, contributing to a more comfortable and durable structure.

Table of Comparison

| Feature | Insulating Concrete Forms (ICFs) | Traditional Concrete |

|---|---|---|

| Energy Efficiency | High R-value insulation; reduces heating and cooling costs | Low insulation; requires additional insulation materials |

| Construction Speed | Faster assembly with integrated insulation forms | Slower due to formwork setup and curing time |

| Structural Strength | Strong, durable, and resistant to fire and pests | Strong and durable; widely tested in construction |

| Sound Insulation | Excellent soundproofing properties | Minimal sound insulation without added materials |

| Cost | Higher upfront cost; lower long-term energy expenses | Lower initial cost; higher energy costs over time |

| Environmental Impact | More sustainable with energy savings and reduced waste | Higher carbon footprint due to cement production |

Introduction to Insulating Concrete Forms (ICFs) and Traditional Concrete

Insulating Concrete Forms (ICFs) are hollow blocks or panels made of expanded polystyrene that serve as permanent insulation for concrete walls, improving energy efficiency and reducing thermal bridging compared to traditional concrete construction. Traditional concrete involves pouring concrete into temporary formwork which is removed after curing, providing strong structural support but limited insulation properties. ICFs combine the durability of concrete with enhanced insulation and soundproofing, making them ideal for energy-conscious building projects.

Structural Strength: ICFs vs Traditional Concrete

Insulating concrete forms (ICFs) provide enhanced structural strength compared to traditional concrete due to their superior load-bearing capacity and resistance to lateral forces such as wind and seismic activity. The combination of reinforced concrete with expanded polystyrene in ICFs creates a more durable and impact-resistant wall system. Traditional concrete relies solely on its compressive strength, whereas ICFs distribute stress more evenly, resulting in improved overall structural integrity.

Thermal Performance and Energy Efficiency

Insulating concrete forms (ICFs) offer superior thermal performance compared to traditional concrete, providing continuous insulation and reducing thermal bridging through their composite structure of foam panels and concrete core. This enhanced thermal resistance significantly lowers energy consumption for heating and cooling by maintaining stable indoor temperatures. As a result, buildings constructed with ICFs achieve higher energy efficiency ratings and long-term cost savings in climate control.

Installation Process and Construction Time

Insulating concrete forms (ICFs) streamline the installation process by combining formwork, insulation, and reinforcement into a single system, significantly reducing construction time compared to traditional concrete methods, which require separate steps for form setup, insulation placement, and curing. ICFs enable faster assembly through lightweight interlocking panels, accelerating the building schedule while ensuring superior energy efficiency and structural integrity. Traditional concrete construction involves labor-intensive form building and longer curing periods, often extending project timelines and increasing labor costs.

Cost Comparison: Upfront and Long-term

Insulating concrete forms (ICFs) typically have a higher upfront cost compared to traditional concrete due to specialized materials and installation processes. However, ICFs offer superior energy efficiency, resulting in significant long-term savings on heating and cooling expenses. Traditional concrete may have lower initial costs but often leads to higher ongoing energy costs and increased maintenance over time.

Soundproofing Capabilities

Insulating concrete forms (ICFs) offer superior soundproofing capabilities compared to traditional concrete due to their composite structure of rigid foam insulation and reinforced concrete, which effectively absorbs and dampens sound waves. The high-density core combined with the insulating layers creates an exceptional barrier against airborne noise and vibration, making ICFs ideal for residential and commercial buildings in noisy environments. In contrast, traditional concrete walls lack the additional insulation layer, resulting in lower acoustic performance and higher sound transmission.

Environmental Impact and Sustainability

Insulating concrete forms (ICFs) significantly reduce environmental impact compared to traditional concrete by enhancing energy efficiency through superior thermal insulation, which lowers heating and cooling demands. The use of ICFs incorporates recycled materials and reduces waste during construction, contributing to sustainability goals. Traditional concrete production generates higher CO2 emissions due to intensive cement manufacturing, whereas ICFs promote long-term energy savings and reduced carbon footprint throughout a building's lifecycle.

Design Flexibility and Architectural Options

Insulating concrete forms (ICFs) offer superior design flexibility compared to traditional concrete by allowing for complex shapes, curves, and varied wall thicknesses without compromising structural integrity. ICFs provide enhanced architectural options such as integrated insulation and seamless finishes, enabling innovative design elements like large openings and customized facades. Traditional concrete typically limits design versatility due to rigid formwork and longer curing times, restricting architectural creativity in residential and commercial construction.

Durability and Maintenance Needs

Insulating concrete forms (ICFs) provide superior durability by combining reinforced concrete with insulation layers that resist moisture, pests, and temperature fluctuations, reducing the risk of cracks and structural damage over time. Traditional concrete, while strong, often requires periodic sealing and repairs to address surface wear and potential water infiltration. Maintenance needs for ICF structures are typically lower due to their integrated design, which enhances longevity and minimizes ongoing upkeep compared to conventional concrete construction.

Best Applications: When to Choose ICFs or Traditional Concrete

Insulating concrete forms (ICFs) are best suited for energy-efficient residential and commercial buildings requiring superior thermal insulation and soundproofing. Traditional concrete excels in applications where high structural strength, rapid curing, and cost efficiency are critical, such as infrastructure projects and industrial facilities. Selecting ICFs benefits projects aiming for green building certifications, while traditional concrete remains preferable for straightforward, high-load structural elements.

Insulating concrete forms vs Traditional concrete Infographic

productdif.com

productdif.com