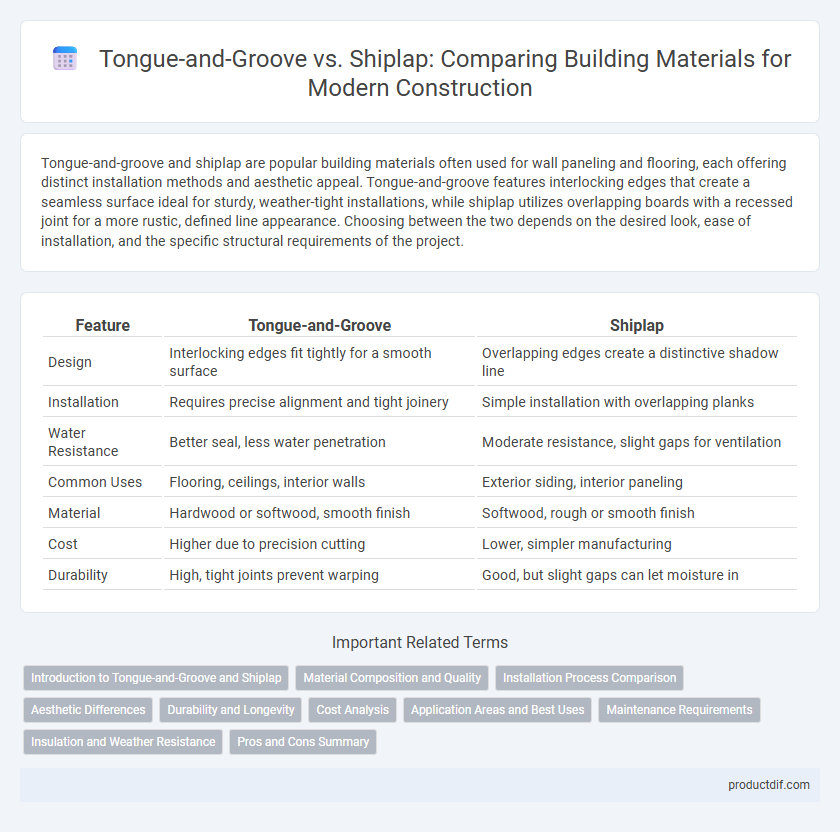

Tongue-and-groove and shiplap are popular building materials often used for wall paneling and flooring, each offering distinct installation methods and aesthetic appeal. Tongue-and-groove features interlocking edges that create a seamless surface ideal for sturdy, weather-tight installations, while shiplap utilizes overlapping boards with a recessed joint for a more rustic, defined line appearance. Choosing between the two depends on the desired look, ease of installation, and the specific structural requirements of the project.

Table of Comparison

| Feature | Tongue-and-Groove | Shiplap |

|---|---|---|

| Design | Interlocking edges fit tightly for a smooth surface | Overlapping edges create a distinctive shadow line |

| Installation | Requires precise alignment and tight joinery | Simple installation with overlapping planks |

| Water Resistance | Better seal, less water penetration | Moderate resistance, slight gaps for ventilation |

| Common Uses | Flooring, ceilings, interior walls | Exterior siding, interior paneling |

| Material | Hardwood or softwood, smooth finish | Softwood, rough or smooth finish |

| Cost | Higher due to precision cutting | Lower, simpler manufacturing |

| Durability | High, tight joints prevent warping | Good, but slight gaps can let moisture in |

Introduction to Tongue-and-Groove and Shiplap

Tongue-and-groove is a woodworking joint where a protruding tongue on one board fits into a corresponding groove on another, ensuring a tight, seamless connection ideal for flooring, paneling, and ceilings. Shiplap features boards with rabbeted edges that overlap horizontally, creating a distinctive shadow line that enhances both weather resistance and aesthetic appeal for exterior and interior wall cladding. Both materials offer durable, interlocking designs that improve structural stability and are popular choices in modern and rustic building projects.

Material Composition and Quality

Tongue-and-groove boards are typically made from hardwood or softwood with precise milling to ensure a tight, interlocking fit that enhances structural stability and resistance to warping. Shiplap consists of overlapping wooden planks often crafted from pine or cedar, valued for its durability and natural resistance to moisture and decay. The choice between tongue-and-groove and shiplap depends heavily on the material quality and intended application, with tongue-and-groove offering superior strength and shiplap providing easier installation and aesthetic versatility.

Installation Process Comparison

Tongue-and-groove installation involves fitting a protruding tongue on one board into a corresponding groove on the adjacent board, creating a tight, interlocking joint that requires precise alignment and occasional use of mallets or clamps for secure fitting. Shiplap installation features rabbeted edges that overlap, allowing for easier, faster placement with nails driven through the face or overlapping edges, making it more forgiving of slight imperfections in board size or wall flatness. Both methods require surface preparation and fastening, but tongue-and-groove typically demands more skill and time for flawless results compared to the simpler, more straightforward shiplap process.

Aesthetic Differences

Tongue-and-groove boards create a tight, seamless fit that enhances a smooth, uniform appearance ideal for traditional and formal interiors. Shiplap features a distinctive recessed groove between each board, producing a shadow line effect that emphasizes texture and dimension, often favored in rustic or farmhouse styles. The choice between these materials significantly impacts wall aesthetics, with tongue-and-groove providing a refined look and shiplap offering a more casual, layered visual appeal.

Durability and Longevity

Tongue-and-groove boards provide superior durability due to their interlocking design, which minimizes gaps and enhances structural integrity, making them ideal for high-traffic or load-bearing surfaces. Shiplap features overlapping edges that offer excellent weather resistance and flexibility in expansion, contributing to its longevity in exterior applications. Both materials can last decades with proper treatment, but tongue-and-groove typically delivers a tighter seal against moisture and warping, extending lifespan in demanding indoor environments.

Cost Analysis

Tongue-and-groove boards typically cost more due to the precision milling required for their interlocking edges, whereas shiplap is often less expensive because of its simpler rabbeted joints. Installation costs for tongue-and-groove can be higher as it requires more skill and time to ensure tight fitting, while shiplap offers quicker and easier installation that reduces labor expenses. Overall, shiplap provides a more budget-friendly option for siding and interior paneling projects, making it popular in cost-conscious builds.

Application Areas and Best Uses

Tongue-and-groove is ideal for flooring, ceilings, and wall paneling due to its tight, interlocking fit that provides a smooth, durable surface resistant to moisture and drafts. Shiplap is best suited for exterior siding and interior accent walls, offering a distinctive gap between boards that enhances ventilation and adds rustic charm. Both materials perform well in residential and commercial construction, with tongue-and-groove preferred for seamless finishes and shiplap favored for decorative appeal and weather resistance.

Maintenance Requirements

Tongue-and-groove boards require regular inspection to ensure the joints remain tight, preventing moisture infiltration and warping, while shiplap's overlapping design naturally enhances water resistance and reduces maintenance frequency. Both materials benefit from periodic sealing or painting to protect against weathering and decay, but tongue-and-groove demands slightly more upkeep due to its tighter joints. Proper ventilation and moisture control are essential for extending the lifespan of both wood paneling options.

Insulation and Weather Resistance

Tongue-and-groove boards interlock tightly, creating a solid barrier that enhances insulation by minimizing air gaps and improving thermal efficiency in building envelopes. Shiplap siding, featuring overlapping edges, provides superior weather resistance by effectively channeling water away and preventing moisture infiltration. Both materials offer distinct advantages, with tongue-and-groove excelling in airtight insulation and shiplap optimizing protection against rain and wind exposure.

Pros and Cons Summary

Tongue-and-groove offers a tighter, more secure fit that minimizes gaps and provides superior strength, making it ideal for flooring and paneling, but it requires precise installation and can be more difficult to repair. Shiplap features overlapping boards that allow for natural expansion and contraction, offering better ventilation and easier installation, yet it can leave small gaps that may let in drafts or moisture. Choosing between the two depends on the desired aesthetic, environmental conditions, and installation skills.

Tongue-and-Groove vs Shiplap Infographic

productdif.com

productdif.com