Screed offers a robust and durable base layer ideal for leveling floors in construction projects, providing excellent strength for heavy loads. Self-leveling compound, on the other hand, flows effortlessly to create a smooth, even surface with minimal manual effort, making it perfect for rapid installations and finishing layers. Choosing between screed and self-leveling compound depends on the required floor strength, installation speed, and the desired final surface finish.

Table of Comparison

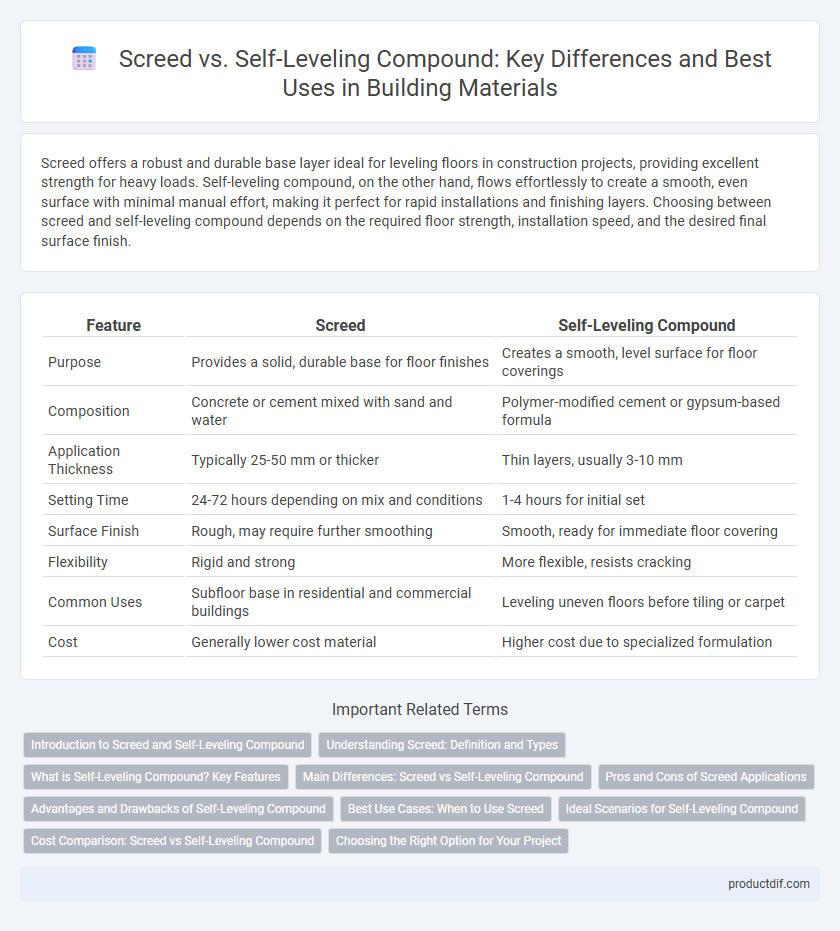

| Feature | Screed | Self-Leveling Compound |

|---|---|---|

| Purpose | Provides a solid, durable base for floor finishes | Creates a smooth, level surface for floor coverings |

| Composition | Concrete or cement mixed with sand and water | Polymer-modified cement or gypsum-based formula |

| Application Thickness | Typically 25-50 mm or thicker | Thin layers, usually 3-10 mm |

| Setting Time | 24-72 hours depending on mix and conditions | 1-4 hours for initial set |

| Surface Finish | Rough, may require further smoothing | Smooth, ready for immediate floor covering |

| Flexibility | Rigid and strong | More flexible, resists cracking |

| Common Uses | Subfloor base in residential and commercial buildings | Leveling uneven floors before tiling or carpet |

| Cost | Generally lower cost material | Higher cost due to specialized formulation |

Introduction to Screed and Self-Leveling Compound

Screed is a durable, cement-based material applied to floors to create a smooth, level surface that enhances structural strength and prepares flooring substrates for finishing layers. Self-leveling compound, composed mainly of cement and polymer additives, flows easily to form an even, flat surface with minimal manual effort, ideal for correcting uneven floors quickly. Both materials serve essential roles in floor preparation, with screed offering robustness and self-leveling compounds providing efficiency and precision.

Understanding Screed: Definition and Types

Screed is a layer of material, typically cement-based, applied to create a smooth and level surface for flooring installation. Common types include traditional sand and cement screed, anhydrite (calcium sulfate) screed, and fast-drying screed, each varying in curing time, thickness, and application method. Understanding these types is essential for selecting the right screed based on project requirements such as load-bearing capacity, drying time, and compatibility with floor finishes.

What is Self-Leveling Compound? Key Features

Self-leveling compound is a polymer-modified cementitious material designed to create smooth, flat surfaces quickly over uneven or rough subfloors. Its key features include high fluidity for easy application, fast curing times that minimize project delays, and excellent adhesion to various substrates such as concrete, wood, and terrazzo. This compound provides a durable, level base ideal for installing flooring materials like tile, carpet, or hardwood.

Main Differences: Screed vs Self-Leveling Compound

Screed is a mixture of cement, sand, and water applied in thicker layers to create a strong, level substrate for floor coverings, often requiring manual leveling and curing time. Self-leveling compound consists of finer ingredients with polymer additives, designed to flow easily and create a perfectly smooth surface quickly, minimizing labor and reducing curing periods. The primary difference lies in application thickness, flowability, and drying time, making self-leveling compounds ideal for fast, precise floor finishing while screeds offer robust structural support.

Pros and Cons of Screed Applications

Screed applications provide a durable, strong surface ideal for high-traffic areas and structural support, offering excellent load-bearing capacity and compatibility with various floor finishes. However, screeds require longer curing times and precise mixing to avoid cracking or uneven surfaces, and installation can be labor-intensive compared to self-leveling compounds. Moisture sensitivity is a concern, necessitating adequate drying periods to prevent adhesion problems or surface defects.

Advantages and Drawbacks of Self-Leveling Compound

Self-leveling compound offers rapid curing times and exceptional flow characteristics, enabling smooth, even surfaces with minimal effort, making it ideal for large floor areas and complex substrates. It requires precise mixing and application conditions, as improper use can lead to cracking or poor adhesion, impacting durability. Despite higher material costs compared to traditional screed, self-leveling compounds reduce labor time and achieve superior flatness, enhancing the performance of flooring finishes such as tiles, vinyl, and hardwood.

Best Use Cases: When to Use Screed

Screed is best used for leveling and creating a solid, durable base on floors with significant unevenness or for embedding underfloor heating pipes. It excels in thick applications where structural strength and long-term stability are required, such as in new construction or heavy-duty commercial flooring. Screed is ideal for substrates needing substantial thickness and uniform load distribution before the final floor finish is applied.

Ideal Scenarios for Self-Leveling Compound

Self-leveling compound is ideal for uneven or rough substrates where a perfectly flat and smooth surface is required for flooring installation. It is particularly beneficial in large commercial spaces or renovations where time efficiency and reduced labor costs are crucial. The compound's ability to quickly cure and provide a durable, level base makes it suitable for tile, vinyl, and hardwood floors.

Cost Comparison: Screed vs Self-Leveling Compound

Screed generally costs less per square meter compared to self-leveling compound, making it a budget-friendly option for large areas. Self-leveling compound, while more expensive, reduces labor costs due to its faster application and smoother finish. The choice depends on balancing initial material expense with installation efficiency and project requirements.

Choosing the Right Option for Your Project

Screed provides a solid, durable base ideal for high-traffic areas and heavy loads, while self-leveling compound offers a smooth, fast-setting surface perfect for thinner applications and quick renovations. Consider screed for traditional screeding over concrete or underfloor heating systems, and choose self-leveling compound when you need rapid installation with minimal thickness variation. Evaluate the project's load requirements, drying times, and substrate conditions to ensure optimal performance and longevity.

Screed vs Self-Leveling Compound Infographic

productdif.com

productdif.com