SIP panels offer superior insulation and energy efficiency compared to traditional stick framing, reducing heating and cooling costs significantly. Their prefabricated nature allows for faster construction times and minimizes on-site waste, enhancing overall sustainability. Stick framing, while more flexible for custom designs and easier to modify during construction, often results in longer build times and increased labor costs.

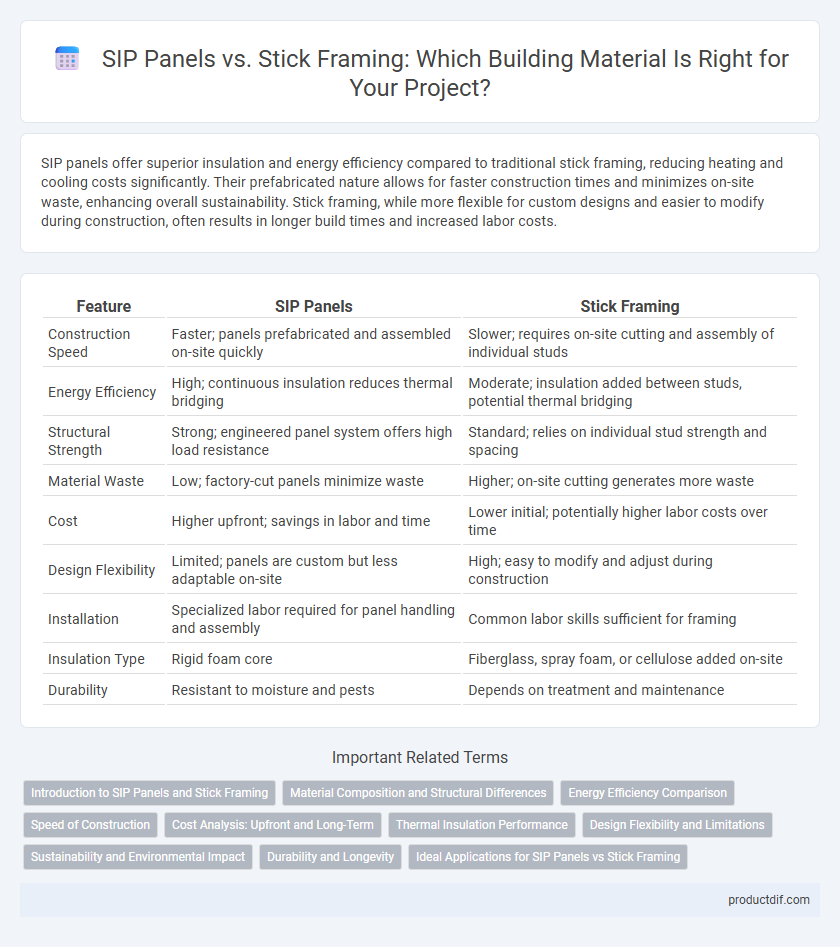

Table of Comparison

| Feature | SIP Panels | Stick Framing |

|---|---|---|

| Construction Speed | Faster; panels prefabricated and assembled on-site quickly | Slower; requires on-site cutting and assembly of individual studs |

| Energy Efficiency | High; continuous insulation reduces thermal bridging | Moderate; insulation added between studs, potential thermal bridging |

| Structural Strength | Strong; engineered panel system offers high load resistance | Standard; relies on individual stud strength and spacing |

| Material Waste | Low; factory-cut panels minimize waste | Higher; on-site cutting generates more waste |

| Cost | Higher upfront; savings in labor and time | Lower initial; potentially higher labor costs over time |

| Design Flexibility | Limited; panels are custom but less adaptable on-site | High; easy to modify and adjust during construction |

| Installation | Specialized labor required for panel handling and assembly | Common labor skills sufficient for framing |

| Insulation Type | Rigid foam core | Fiberglass, spray foam, or cellulose added on-site |

| Durability | Resistant to moisture and pests | Depends on treatment and maintenance |

Introduction to SIP Panels and Stick Framing

Structural Insulated Panels (SIP) consist of rigid foam insulation sandwiched between two structural facings, typically oriented strand board (OSB), providing high thermal performance and airtightness. Stick framing uses dimensional lumber assembled on-site to create a framework that supports walls, floors, and roofs, offering flexibility in design but often requiring more time and labor. SIP panels reduce construction waste and improve energy efficiency compared to conventional stick framing methods.

Material Composition and Structural Differences

SIP panels consist of an insulating foam core sandwiched between two oriented strand board (OSB) layers, offering superior thermal insulation and airtightness compared to stick framing, which uses traditional dimensional lumber studs spaced typically 16 or 24 inches apart. The structural composition of SIP panels provides uniform load distribution and enhanced rigidity, while stick framing relies on load-bearing studs with potential thermal bridging and less continuous insulation. SIP construction reduces installation time due to prefabrication, whereas stick framing demands more on-site labor for assembly and insulation application.

Energy Efficiency Comparison

SIP panels offer superior energy efficiency compared to stick framing due to their continuous insulation and airtight construction, reducing thermal bridging and heat loss. The high R-value of SIP panels significantly lowers heating and cooling costs by maintaining consistent indoor temperatures. Stick framing often requires additional insulation and air sealing measures to approach the same energy performance as SIP panels.

Speed of Construction

SIP panels accelerate construction by combining structural insulation and sheathing in one pre-fabricated unit, significantly reducing on-site labor and assembly time. Stick framing requires individual cutting, fitting, and securing of multiple components, which extends the construction timeline. Using SIP panels can cut framing time by up to 50%, enabling faster project completion and reduced labor costs.

Cost Analysis: Upfront and Long-Term

SIP panels often present higher upfront costs compared to traditional stick framing due to manufacturing and transportation expenses but offer significant long-term savings through enhanced energy efficiency and reduced labor time. Stick framing materials tend to be less expensive initially but may incur higher ongoing costs from air leakage, insulation upgrades, and maintenance repairs. Evaluating total lifecycle expenses reveals that SIP panels can deliver superior value by minimizing utility bills and improving structural performance over time.

Thermal Insulation Performance

SIP panels offer superior thermal insulation performance compared to traditional stick framing due to their continuous insulation layer, minimizing thermal bridging and reducing heat loss. Their rigid foam core provides higher R-values, enhancing energy efficiency and maintaining consistent indoor temperatures. Stick framing typically requires additional insulation materials, which can leave gaps and reduce overall thermal effectiveness.

Design Flexibility and Limitations

SIP panels offer consistent insulation and structural strength but limit design flexibility due to prefab dimensions and wall configurations. Stick framing allows greater customization and complex architectural designs by enabling on-site modifications and diverse material choices. Builders balancing energy efficiency and creative freedom often select SIPs for standardized layouts and stick framing for intricate, adaptable structures.

Sustainability and Environmental Impact

SIP panels offer superior energy efficiency with continuous insulation that reduces thermal bridging, lowering overall energy consumption compared to traditional stick framing. The manufacturing process of SIPs produces less construction waste and utilizes renewable materials like oriented strand board and expanded polystyrene, enhancing sustainability. Stick framing relies heavily on lumber, which can contribute to deforestation, and generates more onsite waste, increasing its environmental footprint relative to SIP panels.

Durability and Longevity

SIP panels offer superior durability compared to traditional stick framing due to their engineered composite structure, which resists warping, rotting, and pest damage. These panels maintain thermal performance and structural integrity over decades, reducing maintenance and repair costs. Stick framing, while flexible for design changes, is more susceptible to moisture infiltration and insect infestation, potentially shortening the building's lifespan.

Ideal Applications for SIP Panels vs Stick Framing

SIP panels are ideal for projects requiring superior energy efficiency, airtight construction, and faster build times, such as residential homes, modular buildings, and commercial structures prioritizing sustainability. Stick framing is better suited for custom designs, complex architectural features, and renovations where flexibility in on-site alterations is essential. Choosing SIP panels enhances thermal performance and reduces labor costs, while stick framing offers adaptability and easier integration of non-standard electrical and plumbing systems.

SIP Panels vs Stick Framing Infographic

productdif.com

productdif.com