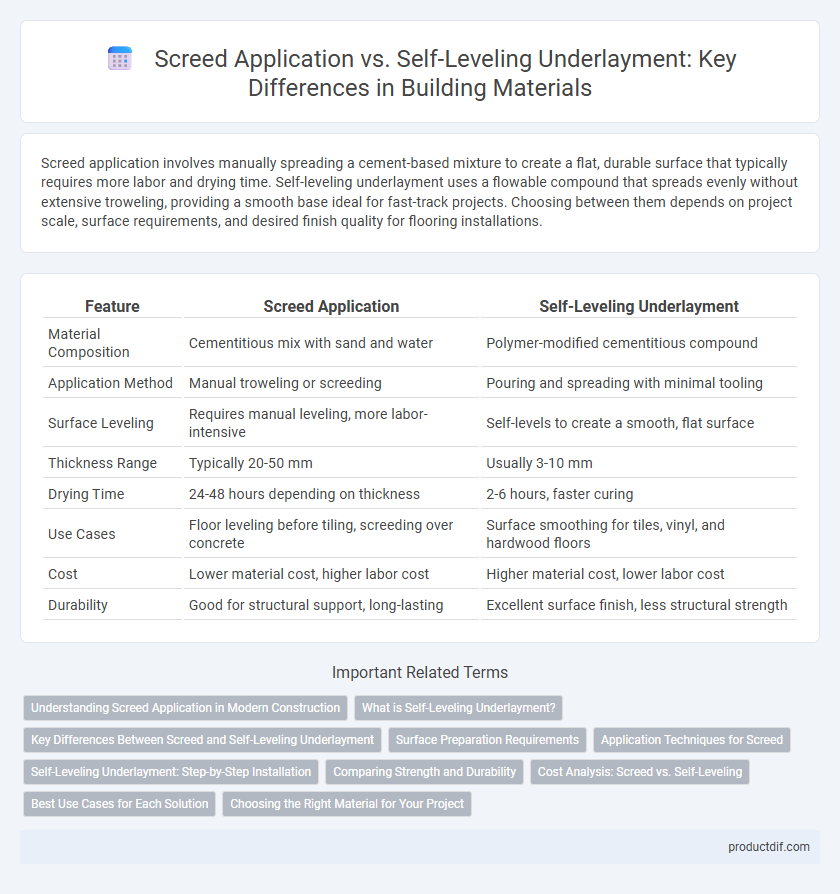

Screed application involves manually spreading a cement-based mixture to create a flat, durable surface that typically requires more labor and drying time. Self-leveling underlayment uses a flowable compound that spreads evenly without extensive troweling, providing a smooth base ideal for fast-track projects. Choosing between them depends on project scale, surface requirements, and desired finish quality for flooring installations.

Table of Comparison

| Feature | Screed Application | Self-Leveling Underlayment |

|---|---|---|

| Material Composition | Cementitious mix with sand and water | Polymer-modified cementitious compound |

| Application Method | Manual troweling or screeding | Pouring and spreading with minimal tooling |

| Surface Leveling | Requires manual leveling, more labor-intensive | Self-levels to create a smooth, flat surface |

| Thickness Range | Typically 20-50 mm | Usually 3-10 mm |

| Drying Time | 24-48 hours depending on thickness | 2-6 hours, faster curing |

| Use Cases | Floor leveling before tiling, screeding over concrete | Surface smoothing for tiles, vinyl, and hardwood floors |

| Cost | Lower material cost, higher labor cost | Higher material cost, lower labor cost |

| Durability | Good for structural support, long-lasting | Excellent surface finish, less structural strength |

Understanding Screed Application in Modern Construction

Screed application in modern construction involves spreading a mixture of cement, sand, and water to create a smooth, level surface that provides structural support and durability for floor finishes. Unlike self-leveling underlayment, which is highly fluid and designed for rapid leveling of uneven floors, screed offers a thicker, more robust base suitable for both indoor and outdoor environments. Accurate screed application ensures optimal floor flatness, load distribution, and long-term performance in residential, commercial, and industrial projects.

What is Self-Leveling Underlayment?

Self-leveling underlayment is a polymer-modified cement-based compound designed to create smooth, flat surfaces on uneven subfloors before the installation of floor coverings. It flows easily due to its high fluidity, filling low spots and minor imperfections to establish a level base quickly. This material is essential for improving floor flatness and ensuring proper adhesion of tiles, vinyl, or hardwood flooring.

Key Differences Between Screed and Self-Leveling Underlayment

Screed is a cement-based mixture typically applied manually to create a sturdy, level base for flooring, while self-leveling underlayment is a flowable compound that spreads and levels itself with minimal effort. Screed requires drying time and manual finishing to achieve a flat surface, whereas self-leveling underlayment offers faster installation and a smoother finish due to its fluid consistency. The choice between screed and self-leveling underlayment depends on project requirements such as surface flatness tolerance, installation speed, and floor type compatibility.

Surface Preparation Requirements

Screed application requires thorough surface preparation, including cleaning and priming the substrate to ensure proper adhesion and prevent cracking. Self-leveling underlayment demands an even more meticulous surface assessment, often involving the removal of dust, oils, and loose particles, followed by priming with compatible primers designed for the product. Proper surface preparation enhances the bonding strength and durability of both screed and self-leveling underlayment applications, reducing the risk of curling, shrinking, or delamination.

Application Techniques for Screed

Screed application involves a manual process where the material is spread and leveled with a straightedge or screed board, requiring skilled labor to ensure uniform thickness and surface smoothness. This technique often necessitates multiple layers and curing time between applications to achieve the desired strength and flatness. Proper screed application improves load-bearing capacity and provides an ideal base for final floor coverings in construction.

Self-Leveling Underlayment: Step-by-Step Installation

Self-leveling underlayment provides a smooth, level surface ideal for installing floor coverings and correcting uneven subfloors. Begin by thoroughly cleaning the substrate and applying a primer to ensure adhesion; then mix the underlayment according to manufacturer instructions for a consistent, lump-free blend. Pour the mixture onto the floor and use a gauge rake or squeegee to spread it evenly, allowing it to flow and self-level naturally before curing, which usually takes 24 hours.

Comparing Strength and Durability

Screed application offers superior compressive strength, typically ranging from 25 to 40 MPa, making it highly durable for heavy traffic and structural support. Self-leveling underlayment provides a smoother surface with moderate strength around 20 to 30 MPa, ideal for finishing layers but less suitable for load-bearing applications. The choice depends on whether the project prioritizes robust structural integrity or a perfectly level surface for subsequent flooring.

Cost Analysis: Screed vs. Self-Leveling

Screed application typically incurs lower initial material costs but demands more labor and time, increasing overall project expenses compared to self-leveling underlayment, which offers faster installation and reduced labor costs despite higher material prices. Self-leveling underlayment provides a smoother finish with fewer potential repairs, potentially lowering long-term maintenance costs relative to traditional screed floors. Evaluating project size and labor availability is crucial for a precise cost comparison between screed and self-leveling underlayment.

Best Use Cases for Each Solution

Screed application is ideal for creating a durable, level base in traditional construction settings, especially where thickness adjustments and structural strength are required. Self-leveling underlayment offers a fast, smooth surface for thin overlays, making it best suited for modern renovations and preparing floors for tile, vinyl, or hardwood installations. Selecting the right solution depends on project needs such as load-bearing capacity, surface finish, and application speed.

Choosing the Right Material for Your Project

Screed application offers a durable, customizable solution for leveling thick floors and heavy-duty projects, making it ideal for traditional concrete substrates and areas requiring high strength. Self-leveling underlayment provides a fast, smooth finish with excellent flow and quick drying times, perfect for thin layers over existing slabs or preparing surfaces for tile and vinyl installations. Selecting the right material depends on factors like floor thickness, drying time, surface type, and the project's specific load requirements to ensure optimal performance and longevity.

Screed Application vs Self-Leveling Underlayment Infographic

productdif.com

productdif.com