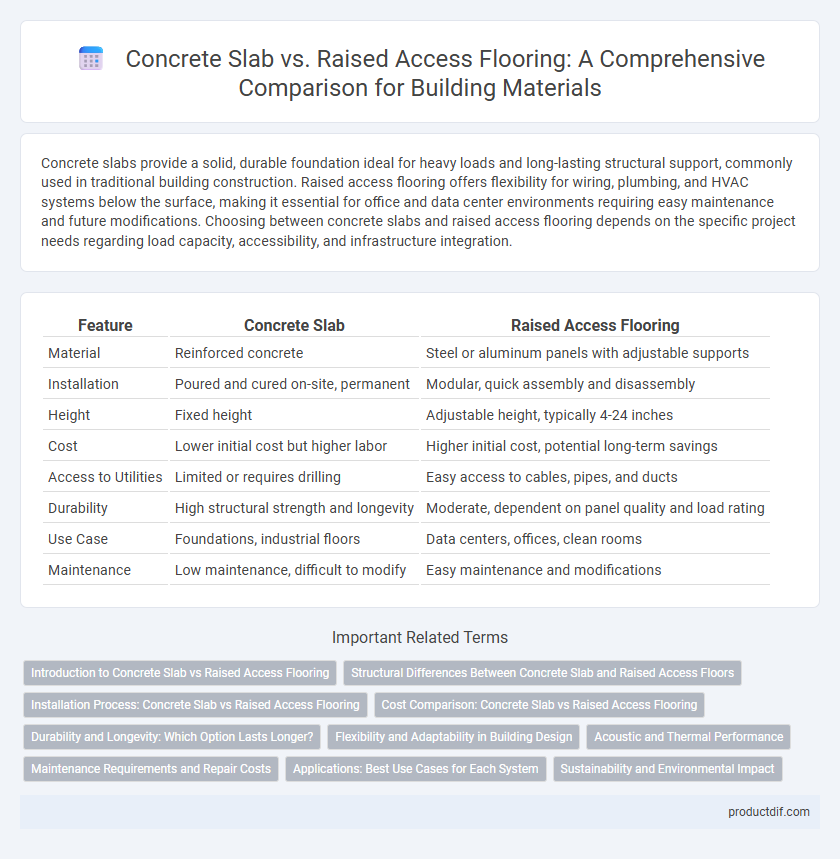

Concrete slabs provide a solid, durable foundation ideal for heavy loads and long-lasting structural support, commonly used in traditional building construction. Raised access flooring offers flexibility for wiring, plumbing, and HVAC systems below the surface, making it essential for office and data center environments requiring easy maintenance and future modifications. Choosing between concrete slabs and raised access flooring depends on the specific project needs regarding load capacity, accessibility, and infrastructure integration.

Table of Comparison

| Feature | Concrete Slab | Raised Access Flooring |

|---|---|---|

| Material | Reinforced concrete | Steel or aluminum panels with adjustable supports |

| Installation | Poured and cured on-site, permanent | Modular, quick assembly and disassembly |

| Height | Fixed height | Adjustable height, typically 4-24 inches |

| Cost | Lower initial cost but higher labor | Higher initial cost, potential long-term savings |

| Access to Utilities | Limited or requires drilling | Easy access to cables, pipes, and ducts |

| Durability | High structural strength and longevity | Moderate, dependent on panel quality and load rating |

| Use Case | Foundations, industrial floors | Data centers, offices, clean rooms |

| Maintenance | Low maintenance, difficult to modify | Easy maintenance and modifications |

Introduction to Concrete Slab vs Raised Access Flooring

Concrete slabs provide a solid, durable foundation widely used in construction for their strength and long lifespan. Raised access flooring offers flexible underfloor space for wiring and ventilation, ideal for commercial buildings requiring adaptability. Each flooring type serves distinct functional needs, influencing project design and utility management decisions.

Structural Differences Between Concrete Slab and Raised Access Floors

Concrete slabs are solid, monolithic structures that provide high load-bearing capacity and durability, commonly used as foundational floors in buildings. Raised access floors consist of modular panels supported by adjustable pedestals, allowing for easy installation of electrical wiring, HVAC systems, and data cables beneath the floor surface. Structurally, concrete slabs offer superior rigidity and thermal mass, while raised access floors prioritize flexibility and accessibility for maintenance and reconfiguration.

Installation Process: Concrete Slab vs Raised Access Flooring

Concrete slabs are installed by pouring and leveling wet concrete directly on a prepared sub-base, requiring curing time for strength development, whereas raised access flooring involves assembling modular panels on a grid of adjustable metal pedestals above the sub-floor. The concrete slab installation demands heavy equipment and skilled labor for mixing, pouring, and finishing, while raised access flooring offers quicker installation with minimal downtime and flexibility for future modifications. Raised access floors enable easy access to underfloor services, contrasting with the permanence and durability of concrete slabs that limit access once cured.

Cost Comparison: Concrete Slab vs Raised Access Flooring

Concrete slabs generally offer a lower initial installation cost compared to raised access flooring, making them a more budget-friendly choice for large-scale construction projects. Raised access flooring entails higher upfront expenses due to modular panel systems and the need for specialized installation, but it provides long-term savings through easy access for electrical and HVAC maintenance. When evaluating total lifecycle costs, raised access flooring can be more economical in facilities requiring frequent infrastructure upgrades or modifications.

Durability and Longevity: Which Option Lasts Longer?

Concrete slabs offer exceptional durability and longevity due to their solid, monolithic structure, often lasting over 50 years with minimal maintenance. Raised access flooring, typically composed of modular panels supported by a grid of pedestals, provides flexibility but generally has a shorter lifespan, around 15 to 20 years, depending on material quality and usage. For long-term structural integrity and resistance to heavy loads, concrete slabs are the preferred choice in building construction.

Flexibility and Adaptability in Building Design

Concrete slabs provide a solid, durable foundation ideal for static load-bearing applications but lack flexibility for future modifications or access to underfloor utilities. Raised access flooring systems offer superior adaptability by allowing easy reconfiguration of wiring, HVAC, and plumbing, enhancing building design flexibility. This modular approach supports frequent changes in office layouts and technology upgrades, making it a preferred choice in dynamic commercial environments.

Acoustic and Thermal Performance

Concrete slabs offer superior thermal mass, providing enhanced heat retention and energy efficiency in building structures, while their dense composition significantly reduces sound transmission for optimal acoustic performance. Raised access flooring systems provide effective acoustic insulation by incorporating sound-dampening panels or underlayments, though their thermal performance is generally lower due to the air gap beneath the panels reducing heat retention. Choosing between the two depends on project requirements for thermal stability and sound isolation, with concrete slabs excelling in long-term energy efficiency and raised flooring supporting flexible acoustic management.

Maintenance Requirements and Repair Costs

Concrete slabs require minimal maintenance with occasional sealing and crack repairs, resulting in lower long-term repair costs. Raised access flooring demands regular inspection and cleaning to prevent panel displacement and damage to underfloor systems, leading to higher maintenance expenses. Repair costs for raised access flooring can escalate due to the need for specialized components and skilled labor.

Applications: Best Use Cases for Each System

Concrete slabs provide a durable, load-bearing surface ideal for heavy industrial applications, commercial buildings, and outdoor pavements where strength and longevity are critical. Raised access flooring is best suited for office spaces, data centers, and environments requiring flexible cable management, HVAC integration, and easy access to underfloor utilities. Each system's application depends on structural demands, accessibility needs, and the complexity of mechanical and electrical installations.

Sustainability and Environmental Impact

Concrete slabs offer high durability and thermal mass, contributing to energy efficiency but involve significant CO2 emissions during cement production, impacting sustainability negatively. Raised access flooring systems, often made from recyclable materials like steel and aluminum, facilitate easy maintenance and adaptability, reducing waste over time and supporting circular economy principles. Choosing raised access flooring can minimize environmental impact by enabling flexible space reconfigurations without extensive demolition compared to traditional concrete slabs.

Concrete slab vs Raised access flooring Infographic

productdif.com

productdif.com