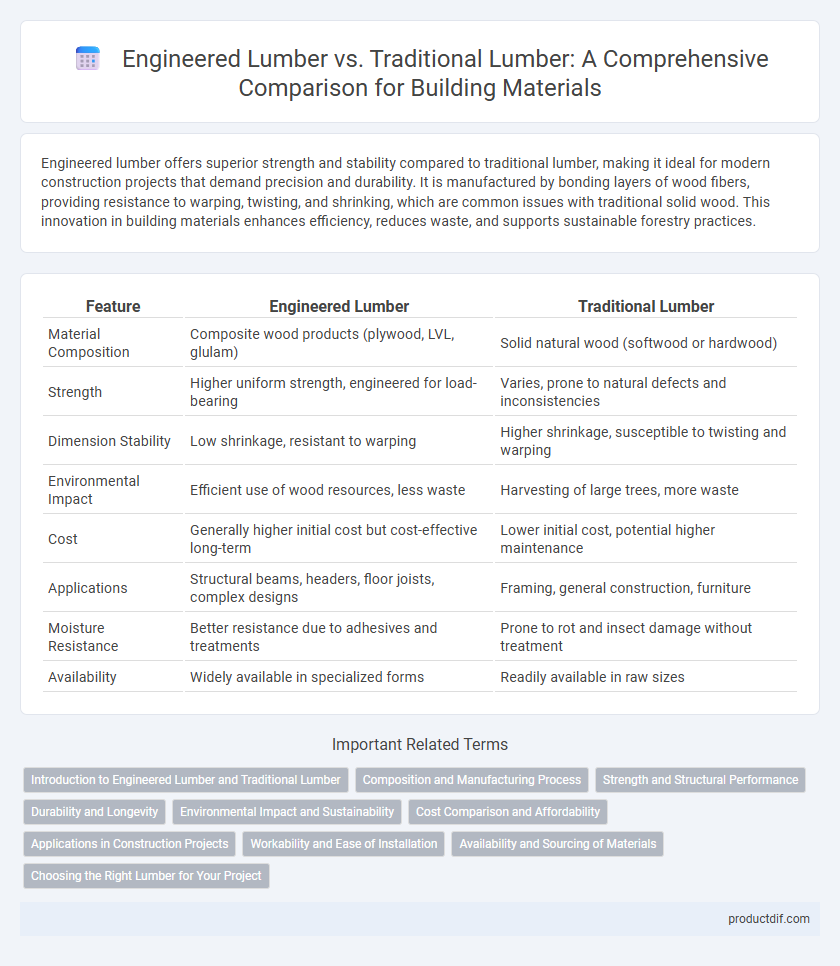

Engineered lumber offers superior strength and stability compared to traditional lumber, making it ideal for modern construction projects that demand precision and durability. It is manufactured by bonding layers of wood fibers, providing resistance to warping, twisting, and shrinking, which are common issues with traditional solid wood. This innovation in building materials enhances efficiency, reduces waste, and supports sustainable forestry practices.

Table of Comparison

| Feature | Engineered Lumber | Traditional Lumber |

|---|---|---|

| Material Composition | Composite wood products (plywood, LVL, glulam) | Solid natural wood (softwood or hardwood) |

| Strength | Higher uniform strength, engineered for load-bearing | Varies, prone to natural defects and inconsistencies |

| Dimension Stability | Low shrinkage, resistant to warping | Higher shrinkage, susceptible to twisting and warping |

| Environmental Impact | Efficient use of wood resources, less waste | Harvesting of large trees, more waste |

| Cost | Generally higher initial cost but cost-effective long-term | Lower initial cost, potential higher maintenance |

| Applications | Structural beams, headers, floor joists, complex designs | Framing, general construction, furniture |

| Moisture Resistance | Better resistance due to adhesives and treatments | Prone to rot and insect damage without treatment |

| Availability | Widely available in specialized forms | Readily available in raw sizes |

Introduction to Engineered Lumber and Traditional Lumber

Engineered lumber is manufactured by bonding wood strands, fibers, or veneers with adhesives to create strong, uniform panels designed for specific structural applications. Traditional lumber consists of solid wood sections cut directly from trees, often exhibiting natural variations and imperfections. Engineered lumber offers enhanced dimensional stability and strength compared to the variability found in traditional lumber, making it a preferred choice for modern construction projects.

Composition and Manufacturing Process

Engineered lumber is composed of wood fibers, strands, or veneers bonded with adhesives under heat and pressure, resulting in high-performance structural components like laminated veneer lumber (LVL) and oriented strand board (OSB). Traditional lumber consists of solid wood cut directly from trees, maintaining natural grain and knots without alteration. The manufacturing of engineered lumber involves precise layering and adhesive curing, enhancing strength, uniformity, and resistance to warping compared to the simple sawing and drying processes used for traditional lumber.

Strength and Structural Performance

Engineered lumber exhibits superior strength and structural performance compared to traditional lumber due to its composite construction, which reduces defects and enhances load-bearing capacity. Its consistent density and moisture resistance contribute to improved stability and reduced warping or splitting under stress. These characteristics make engineered lumber ideal for applications requiring high strength-to-weight ratios and long-term durability in construction projects.

Durability and Longevity

Engineered lumber offers superior durability and longevity compared to traditional lumber due to its composite construction, which resists warping, splitting, and shrinking. This material maintains structural integrity under varying environmental conditions, making it ideal for long-term projects. Traditional lumber, while natural and widely used, is more susceptible to moisture damage, insect infestation, and decay over time.

Environmental Impact and Sustainability

Engineered lumber offers a more sustainable alternative to traditional lumber by maximizing the use of smaller, fast-growing trees and wood waste, significantly reducing deforestation rates. Its production process requires less energy and generates lower carbon emissions compared to harvesting and processing large logs for traditional lumber. Engineered lumber's efficient resource utilization and longer lifespan contribute to lower environmental impact, making it a preferred choice in eco-friendly construction projects.

Cost Comparison and Affordability

Engineered lumber typically offers a more cost-effective alternative to traditional lumber due to its efficient manufacturing process and use of wood byproducts, resulting in lower material costs. Traditional lumber prices can fluctuate significantly based on species and supply constraints, often making it less affordable for large-scale projects. Overall, engineered lumber provides consistent pricing and improved affordability, especially in construction applications requiring uniform strength and stability.

Applications in Construction Projects

Engineered lumber offers superior dimensional stability and strength compared to traditional lumber, making it ideal for load-bearing beams, floor joists, and roofing in residential and commercial construction. Its uniformity and resistance to warping allow for precise engineering in complex architectural designs and long-span structures. Traditional lumber remains preferred for aesthetic finishes, framing in smaller-scale projects, and applications where natural wood grain is valued.

Workability and Ease of Installation

Engineered lumber offers superior workability due to its uniform composition and precision manufacturing, resulting in fewer knots and defects compared to traditional lumber. Its consistent dimensions and lighter weight enhance ease of installation, allowing for faster assembly and reduced labor costs on construction sites. Traditional lumber, while sturdy, often requires more on-site adjustments and can vary in quality, leading to increased time and effort during installation.

Availability and Sourcing of Materials

Engineered lumber benefits from a more consistent availability due to its reliance on wood fibers, veneers, or strands sourced from fast-growing, sustainably managed forests, ensuring steady supply chains. Traditional lumber availability depends heavily on the harvesting cycles and regional forest conditions, which can lead to variability in quality and supply, especially in areas facing deforestation or logging restrictions. Sourcing engineered lumber supports efficient material use and reduces waste, while traditional lumber sourcing may require larger, older trees and longer growth periods, impacting long-term sustainability.

Choosing the Right Lumber for Your Project

Engineered lumber offers superior strength, stability, and resistance to warping compared to traditional lumber, making it ideal for projects requiring precise dimensions and durability. Traditional lumber, often preferred for its natural appearance and ease of customization, remains a cost-effective option for simpler structures and aesthetic applications. Selecting the right lumber depends on project requirements such as load-bearing capacity, environmental exposure, and budget constraints to optimize performance and longevity.

Engineered Lumber vs Traditional Lumber Infographic

productdif.com

productdif.com