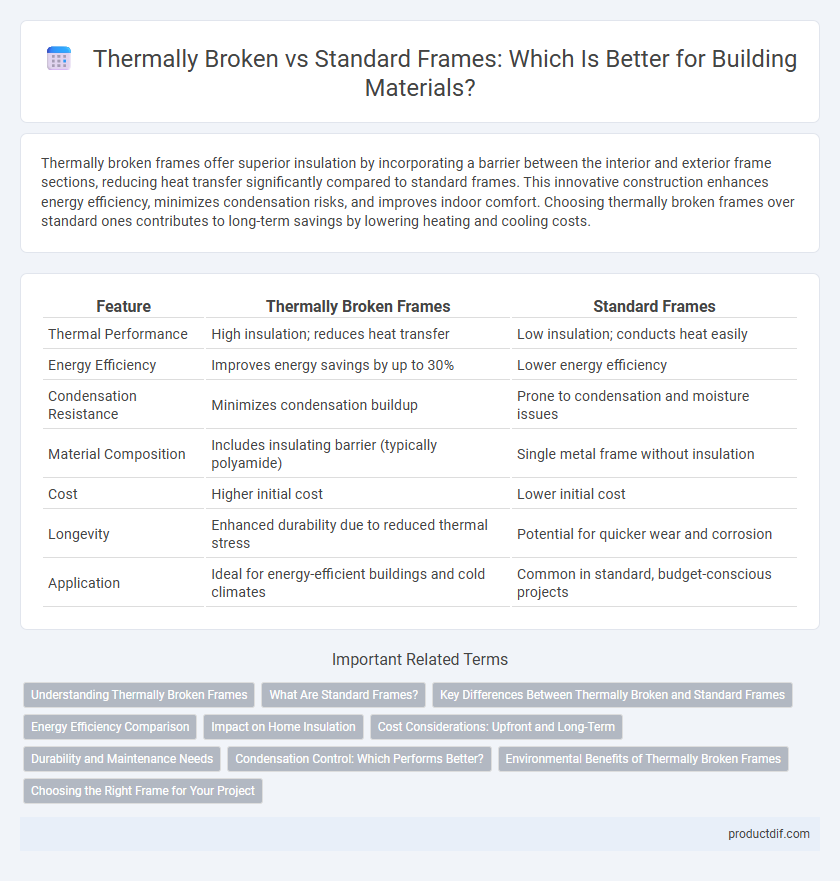

Thermally broken frames offer superior insulation by incorporating a barrier between the interior and exterior frame sections, reducing heat transfer significantly compared to standard frames. This innovative construction enhances energy efficiency, minimizes condensation risks, and improves indoor comfort. Choosing thermally broken frames over standard ones contributes to long-term savings by lowering heating and cooling costs.

Table of Comparison

| Feature | Thermally Broken Frames | Standard Frames |

|---|---|---|

| Thermal Performance | High insulation; reduces heat transfer | Low insulation; conducts heat easily |

| Energy Efficiency | Improves energy savings by up to 30% | Lower energy efficiency |

| Condensation Resistance | Minimizes condensation buildup | Prone to condensation and moisture issues |

| Material Composition | Includes insulating barrier (typically polyamide) | Single metal frame without insulation |

| Cost | Higher initial cost | Lower initial cost |

| Longevity | Enhanced durability due to reduced thermal stress | Potential for quicker wear and corrosion |

| Application | Ideal for energy-efficient buildings and cold climates | Common in standard, budget-conscious projects |

Understanding Thermally Broken Frames

Thermally broken frames incorporate a non-metallic insulating barrier between the interior and exterior frame components, significantly reducing heat transfer and improving energy efficiency in buildings. Unlike standard frames, which are made entirely of metal and conduct heat readily, thermally broken frames help maintain indoor temperature stability and reduce condensation risks. This thermal barrier plays a crucial role in enhancing the overall insulation performance of windows and doors, contributing to lower energy costs and increased occupant comfort.

What Are Standard Frames?

Standard frames are typically constructed from non-insulated metal or aluminum materials, allowing heat and cold to pass through easily. They lack the thermal barrier that thermally broken frames provide, resulting in decreased energy efficiency and increased heat transfer. Standard frames are often chosen for budget-conscious projects where thermal performance is less critical.

Key Differences Between Thermally Broken and Standard Frames

Thermally broken frames feature an insulating barrier between the interior and exterior parts of the frame, significantly reducing thermal conductivity and improving energy efficiency compared to standard frames. Standard frames, typically made from aluminum or steel without this barrier, allow heat to transfer freely, leading to higher energy loss and potential condensation issues. This key difference enhances indoor comfort and lowers heating and cooling costs in buildings using thermally broken frames.

Energy Efficiency Comparison

Thermally broken frames significantly enhance energy efficiency by incorporating a non-metallic barrier between the interior and exterior frame sections, reducing thermal conductivity and minimizing heat transfer. In contrast, standard frames lack this insulation feature, allowing more heat to pass through, which increases energy loss and utility costs. Studies show that thermally broken frames can improve overall building insulation performance by up to 50%, making them ideal for energy-conscious construction projects.

Impact on Home Insulation

Thermally broken frames significantly enhance home insulation by incorporating a non-conductive material between the interior and exterior frame sections, reducing thermal bridging and minimizing heat transfer. Standard frames, typically made from continuous metal, allow more heat to escape or enter, leading to higher energy costs and less effective temperature control. Choosing thermally broken frames improves energy efficiency, contributing to lower utility bills and increased indoor comfort.

Cost Considerations: Upfront and Long-Term

Thermally broken frames typically have a higher upfront cost due to advanced insulation materials and manufacturing processes, but they significantly reduce energy expenses over time by minimizing heat transfer. Standard frames are less expensive initially but often lead to increased heating and cooling costs because of poor thermal performance. Investing in thermally broken frames enhances overall cost efficiency by lowering utility bills and increasing building energy ratings.

Durability and Maintenance Needs

Thermally broken frames feature a barrier of insulating material between the interior and exterior frame sections, significantly enhancing durability by reducing condensation and preventing corrosion compared to standard frames. These frames require less frequent maintenance, as the thermal break minimizes moisture infiltration that often leads to rust and frame degradation. Standard frames, typically made of continuous metal, are more prone to thermal bridging, which accelerates wear and increases the need for regular upkeep to maintain structural integrity and appearance.

Condensation Control: Which Performs Better?

Thermally broken frames outperform standard frames in condensation control by incorporating a non-metal insulating barrier that reduces thermal bridging, significantly lowering interior surface temperatures where condensation typically forms. Standard frames, made entirely of conductive materials like aluminum, facilitate heat transfer between indoor and outdoor environments, increasing the risk of moisture buildup and mold growth. Studies demonstrate thermally broken frames maintain surface temperatures closer to room temperature, effectively minimizing condensation and improving indoor air quality.

Environmental Benefits of Thermally Broken Frames

Thermally broken frames significantly reduce heat transfer by incorporating insulating barriers between frame components, resulting in improved energy efficiency and lower greenhouse gas emissions. This enhanced thermal performance minimizes the need for heating and cooling, thereby reducing the building's overall carbon footprint. Compared to standard frames, thermally broken frames contribute to sustainable construction practices by promoting energy conservation and supporting environmentally responsible building designs.

Choosing the Right Frame for Your Project

Thermally broken frames offer superior insulation by incorporating a non-metallic barrier within the frame, reducing heat transfer and enhancing energy efficiency in buildings. Standard frames, typically made from aluminum or steel without thermal breaks, are more prone to condensation and thermal bridging, which can increase energy costs. Selecting the right frame depends on project requirements such as climate, budget, and energy efficiency goals, where thermally broken frames are ideal for cold climates and sustainable building practices.

Thermally Broken Frames vs Standard Frames Infographic

productdif.com

productdif.com