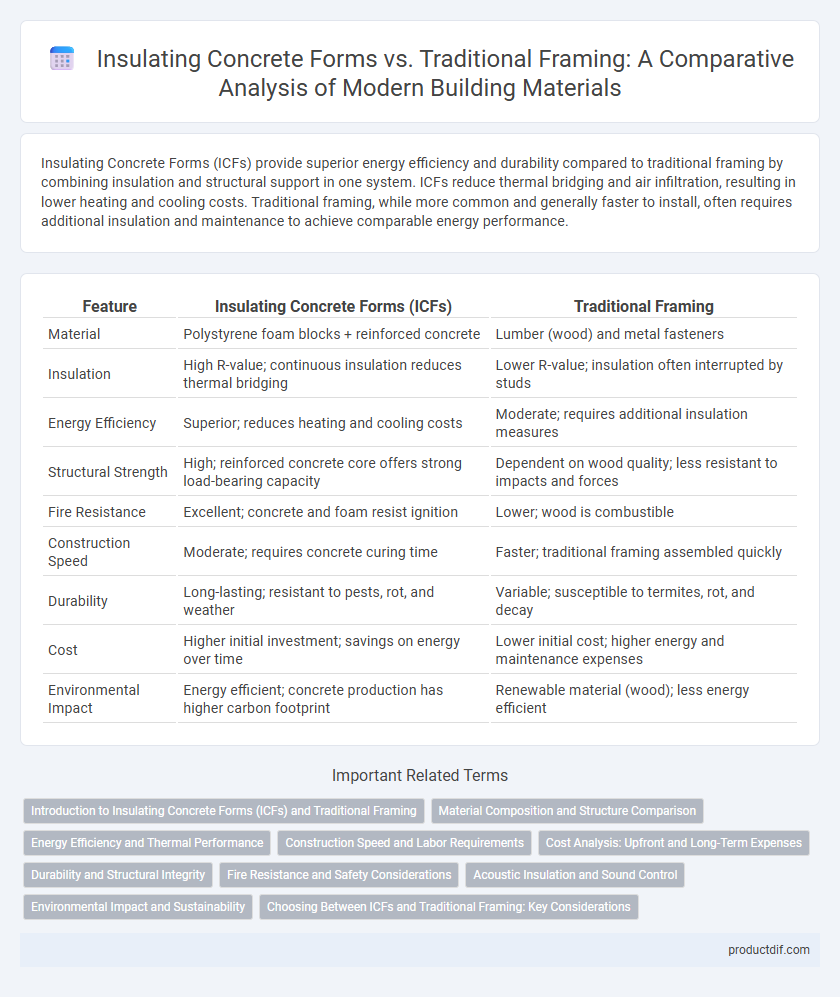

Insulating Concrete Forms (ICFs) provide superior energy efficiency and durability compared to traditional framing by combining insulation and structural support in one system. ICFs reduce thermal bridging and air infiltration, resulting in lower heating and cooling costs. Traditional framing, while more common and generally faster to install, often requires additional insulation and maintenance to achieve comparable energy performance.

Table of Comparison

| Feature | Insulating Concrete Forms (ICFs) | Traditional Framing |

|---|---|---|

| Material | Polystyrene foam blocks + reinforced concrete | Lumber (wood) and metal fasteners |

| Insulation | High R-value; continuous insulation reduces thermal bridging | Lower R-value; insulation often interrupted by studs |

| Energy Efficiency | Superior; reduces heating and cooling costs | Moderate; requires additional insulation measures |

| Structural Strength | High; reinforced concrete core offers strong load-bearing capacity | Dependent on wood quality; less resistant to impacts and forces |

| Fire Resistance | Excellent; concrete and foam resist ignition | Lower; wood is combustible |

| Construction Speed | Moderate; requires concrete curing time | Faster; traditional framing assembled quickly |

| Durability | Long-lasting; resistant to pests, rot, and weather | Variable; susceptible to termites, rot, and decay |

| Cost | Higher initial investment; savings on energy over time | Lower initial cost; higher energy and maintenance expenses |

| Environmental Impact | Energy efficient; concrete production has higher carbon footprint | Renewable material (wood); less energy efficient |

Introduction to Insulating Concrete Forms (ICFs) and Traditional Framing

Insulating Concrete Forms (ICFs) are hollow foam blocks or panels stacked to create walls, then filled with reinforced concrete, offering superior energy efficiency and soundproofing compared to traditional framing. Traditional framing uses wood or steel studs covered with drywall and insulation, favored for its cost-effectiveness and wide familiarity in residential construction. ICFs provide enhanced durability, moisture resistance, and thermal insulation, while traditional framing allows for faster construction and easier modifications.

Material Composition and Structure Comparison

Insulating Concrete Forms (ICFs) consist of rigid foam panels filled with reinforced concrete, combining thermal insulation and structural strength in a single assembly, unlike traditional wood or metal framing that relies primarily on studs with separate insulation materials. ICFs provide continuous insulation with reduced thermal bridging, enhancing energy efficiency, whereas traditional framing typically creates gaps where heat loss can occur due to stud penetrations. The composite structure of ICFs offers superior durability, fire resistance, and soundproofing compared to the layered assembly of traditional framing systems.

Energy Efficiency and Thermal Performance

Insulating Concrete Forms (ICFs) provide superior energy efficiency compared to traditional wood framing by offering continuous insulation and reducing thermal bridging, resulting in lower heating and cooling costs. ICF walls maintain consistent indoor temperatures due to their high thermal mass and R-values typically ranging from R-20 to R-30, outperforming traditional framing with standard fiberglass insulation. The enhanced airtightness of ICF construction minimizes energy loss, contributing to greater overall thermal performance in residential and commercial buildings.

Construction Speed and Labor Requirements

Insulating Concrete Forms (ICFs) streamline construction by combining insulation and structural forms, reducing assembly time compared to traditional framing which involves multiple steps like installing studs, sheathing, and insulation separately. ICF systems typically require less skilled labor and fewer workers on-site, accelerating project timelines. Traditional framing demands more labor-intensive processes and coordination, often increasing construction duration and overall labor costs.

Cost Analysis: Upfront and Long-Term Expenses

Insulating Concrete Forms (ICFs) typically have higher upfront costs compared to traditional wood framing due to materials and specialized labor requirements. However, the long-term expenses with ICFs are lower, as increased energy efficiency reduces heating and cooling bills, and durability minimizes maintenance and repair costs. Traditional framing may offer initial savings but often incurs higher lifetime expenses from insulation retrofit and vulnerability to moisture and pests.

Durability and Structural Integrity

Insulating Concrete Forms (ICFs) offer superior durability and structural integrity compared to traditional wood framing due to their reinforced concrete core, which provides enhanced resistance to fire, pests, and adverse weather conditions. The continuous insulation and solid construction reduce thermal bridging and improve overall building stability, resulting in longer lifespan and lower maintenance costs. In contrast, traditional framing is more susceptible to moisture damage, warping, and termite infestations, often requiring more frequent repairs and replacements.

Fire Resistance and Safety Considerations

Insulating Concrete Forms (ICFs) provide superior fire resistance compared to traditional wood framing due to their dense concrete core, which can withstand high temperatures and prevent flame spread for extended periods. ICFs meet or exceed fire safety codes such as ASTM E119, offering enhanced structural integrity during fires, whereas traditional framing is more vulnerable to rapid combustion and structural failure. The inherent fire-resistant properties of ICFs contribute to safer building environments and reduced risk of fire-related damage.

Acoustic Insulation and Sound Control

Insulating Concrete Forms (ICFs) provide superior acoustic insulation compared to traditional wood or steel framing due to their dense concrete core combined with insulating foam layers, effectively reducing airborne sound transmission and impact noise. The mass and airtight seals of ICF construction create a continuous sound barrier, achieving higher Sound Transmission Class (STC) ratings, often exceeding 50, which is ideal for noise-sensitive environments. Traditional framing relies heavily on additional drywall and insulation materials to approach similar sound control levels but generally falls short of the inherent noise dampening capabilities of ICF systems.

Environmental Impact and Sustainability

Insulating Concrete Forms (ICFs) offer superior environmental benefits compared to traditional framing by significantly reducing energy consumption through enhanced thermal insulation and airtight construction. ICFs utilize recycled materials and contribute to lower greenhouse gas emissions over the building's life cycle, whereas traditional wood framing often involves deforestation and higher waste generation. The durability and energy efficiency of ICF construction result in long-term sustainability advantages, making it a greener choice for eco-conscious building projects.

Choosing Between ICFs and Traditional Framing: Key Considerations

Insulating Concrete Forms (ICFs) offer superior energy efficiency and enhanced soundproofing compared to traditional wood or steel framing, making them ideal for sustainable building projects. Traditional framing provides faster construction times and greater flexibility for design modifications, often resulting in lower initial costs. Key considerations when choosing between ICFs and traditional framing include budget constraints, climate requirements, insulation needs, and long-term energy savings.

Insulating Concrete Forms vs Traditional Framing Infographic

productdif.com

productdif.com