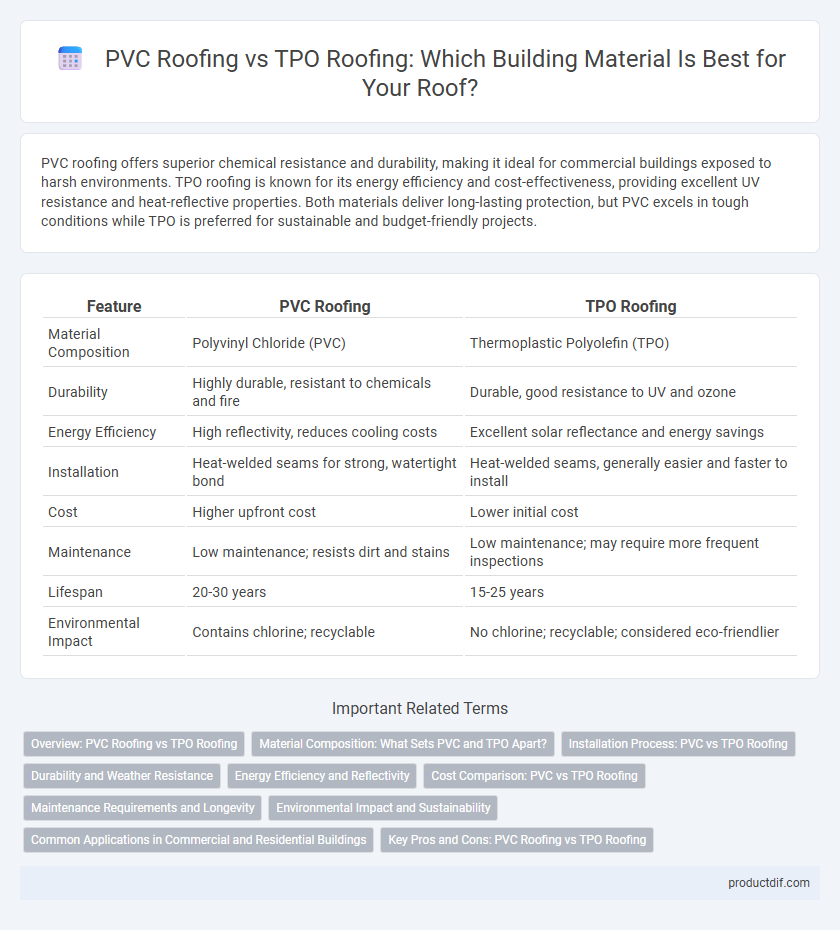

PVC roofing offers superior chemical resistance and durability, making it ideal for commercial buildings exposed to harsh environments. TPO roofing is known for its energy efficiency and cost-effectiveness, providing excellent UV resistance and heat-reflective properties. Both materials deliver long-lasting protection, but PVC excels in tough conditions while TPO is preferred for sustainable and budget-friendly projects.

Table of Comparison

| Feature | PVC Roofing | TPO Roofing |

|---|---|---|

| Material Composition | Polyvinyl Chloride (PVC) | Thermoplastic Polyolefin (TPO) |

| Durability | Highly durable, resistant to chemicals and fire | Durable, good resistance to UV and ozone |

| Energy Efficiency | High reflectivity, reduces cooling costs | Excellent solar reflectance and energy savings |

| Installation | Heat-welded seams for strong, watertight bond | Heat-welded seams, generally easier and faster to install |

| Cost | Higher upfront cost | Lower initial cost |

| Maintenance | Low maintenance; resists dirt and stains | Low maintenance; may require more frequent inspections |

| Lifespan | 20-30 years | 15-25 years |

| Environmental Impact | Contains chlorine; recyclable | No chlorine; recyclable; considered eco-friendlier |

Overview: PVC Roofing vs TPO Roofing

PVC roofing features a single-ply membrane known for its durability, chemical resistance, and strong seam integrity, making it ideal for commercial and industrial buildings. TPO roofing, also a single-ply system, offers excellent energy efficiency through high solar reflectivity and heat-welded seams that provide flexibility and cost-effectiveness. Both materials resist UV radiation and punctures, but PVC tends to outperform TPO in chemical resistance and long-term performance under harsh conditions.

Material Composition: What Sets PVC and TPO Apart?

PVC roofing is composed of polyvinyl chloride, a durable thermoplastic known for its chemical resistance and flexibility, while TPO roofing consists of a blend of polypropylene and ethylene-propylene rubber, offering excellent UV resistance and heat-weldable seams. The chlorine content in PVC provides inherent fire retardancy, whereas TPO's rubber component enhances impact resistance and weatherability. These material compositions influence their performance, longevity, and suitability for different roofing environments.

Installation Process: PVC vs TPO Roofing

PVC roofing installation involves heat-welding the seams for a strong, waterproof bond, ensuring durability and resistance to weathering. TPO roofing installation also uses heat-welding but typically requires fewer specialized tools, making it faster and often more cost-effective. Both systems demand careful surface preparation and precise seam welding to guarantee long-term performance.

Durability and Weather Resistance

PVC roofing offers superior durability with high resistance to punctures, tears, and chemical exposure, making it ideal for harsh environmental conditions. TPO roofing provides excellent weather resistance, particularly against UV radiation and ozone, ensuring long-term performance without significant degradation. Both materials deliver strong protection against extreme temperatures and moisture, but PVC typically outperforms TPO in terms of lifespan and robustness under heavy stress.

Energy Efficiency and Reflectivity

PVC roofing offers superior energy efficiency due to its high reflectivity rates, typically around 85-90%, which effectively reduces heat absorption and lowers cooling costs. TPO roofing also provides strong reflectivity, usually between 70-80%, contributing to energy savings but generally performs slightly less efficiently than PVC in extreme heat conditions. Both materials are durable and designed to meet energy codes, but PVC's enhanced reflectivity often results in better long-term energy performance for commercial and residential buildings.

Cost Comparison: PVC vs TPO Roofing

PVC roofing typically costs between $6 to $12 per square foot, while TPO roofing averages around $5.50 to $9 per square foot, making TPO generally more affordable upfront. Installation expenses for PVC are often higher due to the complexity of welding seams, whereas TPO offers faster and simpler installation processes. Long-term maintenance costs tend to be lower for PVC because of its superior chemical resistance and durability, which can offset the initial price difference.

Maintenance Requirements and Longevity

PVC roofing offers superior chemical resistance and requires minimal maintenance, often needing only periodic cleaning to prevent dirt buildup and maintain flexibility. TPO roofing, while durable and resistant to UV radiation, demands more frequent inspections and occasional repairs to address potential shrinkage or seam issues. PVC roofs typically have a longer lifespan of 20 to 30 years, whereas TPO roofs generally last around 15 to 20 years under similar conditions.

Environmental Impact and Sustainability

PVC roofing materials contain chlorine and release harmful dioxins during manufacturing and disposal, raising environmental concerns, whereas TPO roofing is typically chlorine-free and considered more eco-friendly due to its recyclability and lower impact on greenhouse gas emissions. TPO roofs often have higher reflectivity, which improves energy efficiency by reducing cooling costs and mitigating urban heat island effects. The sustainability of TPO roofing is further enhanced by its longer lifespan and potential for recycling at the end of its life cycle, making it a preferable choice for environmentally conscious construction projects.

Common Applications in Commercial and Residential Buildings

PVC roofing is commonly used in commercial buildings due to its excellent chemical resistance, durability, and reflective properties, making it ideal for flat or low-slope roofs exposed to harsh weather and contaminants. TPO roofing is favored for both commercial and residential applications because of its cost-effectiveness, energy efficiency, and flexibility, particularly on flat or slightly pitched roofs requiring heat-welded seams for leak resistance. Both materials are suitable for sustainable building projects, with PVC often chosen for environments with higher exposure to chemicals and TPO preferred for its UV resistance and ease of installation.

Key Pros and Cons: PVC Roofing vs TPO Roofing

PVC roofing offers exceptional chemical resistance and durability, making it ideal for industrial and commercial buildings but tends to be more expensive and less flexible in extreme cold climates. TPO roofing provides energy efficiency through high reflectivity and is cost-effective with easy installation, yet it may have shorter lifespan and less proven long-term durability compared to PVC. Both materials deliver heat-welded seams for strong waterproofing but vary significantly in material composition and thermal performance.

PVC roofing vs TPO roofing Infographic

productdif.com

productdif.com