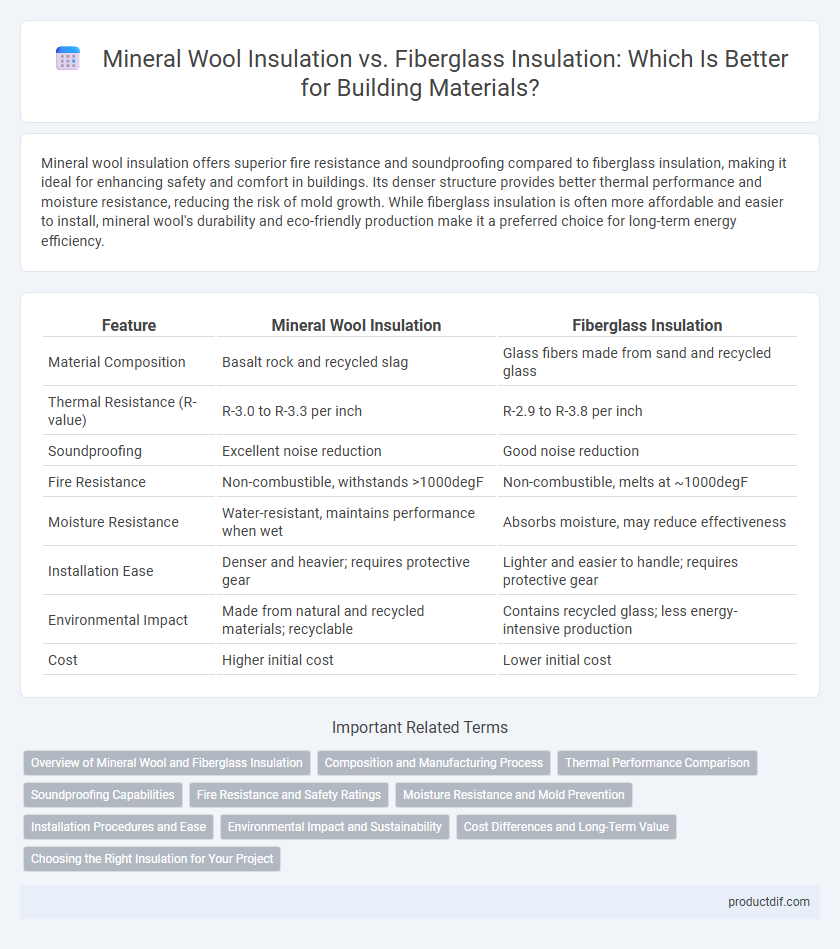

Mineral wool insulation offers superior fire resistance and soundproofing compared to fiberglass insulation, making it ideal for enhancing safety and comfort in buildings. Its denser structure provides better thermal performance and moisture resistance, reducing the risk of mold growth. While fiberglass insulation is often more affordable and easier to install, mineral wool's durability and eco-friendly production make it a preferred choice for long-term energy efficiency.

Table of Comparison

| Feature | Mineral Wool Insulation | Fiberglass Insulation |

|---|---|---|

| Material Composition | Basalt rock and recycled slag | Glass fibers made from sand and recycled glass |

| Thermal Resistance (R-value) | R-3.0 to R-3.3 per inch | R-2.9 to R-3.8 per inch |

| Soundproofing | Excellent noise reduction | Good noise reduction |

| Fire Resistance | Non-combustible, withstands >1000degF | Non-combustible, melts at ~1000degF |

| Moisture Resistance | Water-resistant, maintains performance when wet | Absorbs moisture, may reduce effectiveness |

| Installation Ease | Denser and heavier; requires protective gear | Lighter and easier to handle; requires protective gear |

| Environmental Impact | Made from natural and recycled materials; recyclable | Contains recycled glass; less energy-intensive production |

| Cost | Higher initial cost | Lower initial cost |

Overview of Mineral Wool and Fiberglass Insulation

Mineral wool insulation, made from natural rock or slag fibers, offers superior thermal resistance and excellent soundproofing properties compared to fiberglass insulation, which is composed of fine glass fibers spun into a wool-like texture. Both materials provide fire resistance, but mineral wool boasts a higher melting point, making it more suitable for high-temperature environments. Fiberglass insulation tends to be more affordable and widely available, while mineral wool's density contributes to better moisture resistance and durability.

Composition and Manufacturing Process

Mineral wool insulation is made from natural rock or recycled slag, melted at high temperatures and spun into fibers, providing dense, fire-resistant properties. Fiberglass insulation consists of fine glass fibers created by melting sand and recycled glass, then spun into a wool-like texture, offering lightweight and flexible installation. The manufacturing of mineral wool involves a higher heat process than fiberglass, resulting in distinct thermal and acoustic performance characteristics.

Thermal Performance Comparison

Mineral wool insulation offers superior thermal performance compared to fiberglass insulation due to its higher R-value per inch, typically ranging from 3.7 to 4.2, while fiberglass provides an R-value between 2.9 and 3.8. Mineral wool's dense, non-combustible fibers enhance heat retention and resistance to temperature fluctuations more effectively than the looser structure of fiberglass. This improved thermal efficiency contributes to better energy savings and indoor comfort in both residential and commercial buildings.

Soundproofing Capabilities

Mineral wool insulation offers superior soundproofing capabilities compared to fiberglass insulation due to its higher density and fibrous structure, which effectively absorbs and dampens sound waves. The material's ability to reduce airborne noise and impact sound makes it ideal for enhancing acoustic comfort in residential and commercial buildings. Fiberglass, while economical and widely used, generally provides lower sound attenuation, especially in blocking mid to low-frequency noises.

Fire Resistance and Safety Ratings

Mineral wool insulation offers superior fire resistance with a melting point above 1,200degC, classifying it as non-combustible and providing enhanced safety in fire-prone areas. Fiberglass insulation, while also non-combustible, has a lower melting point around 540degC and may include resin binders that can emit toxic fumes when exposed to high heat. Building codes often favor mineral wool for its higher fire safety ratings and reduced risk of flame spread in residential and commercial construction.

Moisture Resistance and Mold Prevention

Mineral wool insulation offers superior moisture resistance compared to fiberglass insulation due to its dense, hydrophobic structure that repels water and reduces condensation risk. This characteristic significantly lowers the chances of mold growth, making mineral wool an ideal choice for damp environments. Fiberglass insulation, while cost-effective, tends to absorb moisture more readily, increasing susceptibility to mold and compromising indoor air quality over time.

Installation Procedures and Ease

Mineral wool insulation is denser and heavier, requiring careful cutting and fitting to ensure tight installation around studs and pipes, often demanding specialized tools and protective gear due to its fibrous nature. Fiberglass insulation is lighter and more flexible, making it easier to cut and install quickly with basic tools, though it can irritate the skin and respiratory system, necessitating protective clothing and masks. Both materials require precise installation to maximize thermal performance, but fiberglass generally offers faster application with less specialized handling.

Environmental Impact and Sustainability

Mineral wool insulation excels in environmental sustainability due to its high recycled content, often exceeding 70%, and its natural fire resistance, reducing the need for chemical treatments. Fiberglass insulation, while also containing recycled glass, typically has a lower recycled content and requires more energy-intensive manufacturing processes, contributing to a larger carbon footprint. Both materials offer thermal efficiency, but mineral wool's durability and higher recyclability make it a more eco-friendly choice for sustainable building projects.

Cost Differences and Long-Term Value

Mineral wool insulation typically costs more upfront than fiberglass insulation but offers superior fire resistance, soundproofing, and durability, enhancing long-term value by reducing maintenance and replacement expenses. Fiberglass insulation is more affordable initially and widely available, making it a popular choice for budget-conscious projects, yet it may require more frequent replacement over time due to moisture sensitivity and compaction. Evaluating the total lifecycle costs, mineral wool provides better performance and energy savings that can offset higher initial expenses through lower utility bills and increased property protection.

Choosing the Right Insulation for Your Project

Mineral wool insulation offers superior fire resistance and soundproofing benefits compared to fiberglass insulation, making it ideal for projects requiring enhanced safety and noise control. Fiberglass insulation provides excellent thermal performance at a lower cost, suitable for budget-conscious applications prioritizing energy efficiency. Selecting the right insulation depends on factors such as fire ratings, acoustic needs, moisture resistance, and project budget specifications.

Mineral Wool Insulation vs Fiberglass Insulation Infographic

productdif.com

productdif.com