Thermally broken aluminum significantly reduces heat transfer compared to standard aluminum, enhancing energy efficiency in building applications. This material incorporates a non-metallic insulating barrier within the frame, minimizing thermal bridging and improving insulation performance. As a result, thermally broken aluminum contributes to lower heating and cooling costs while maintaining the durability and strength typical of aluminum products.

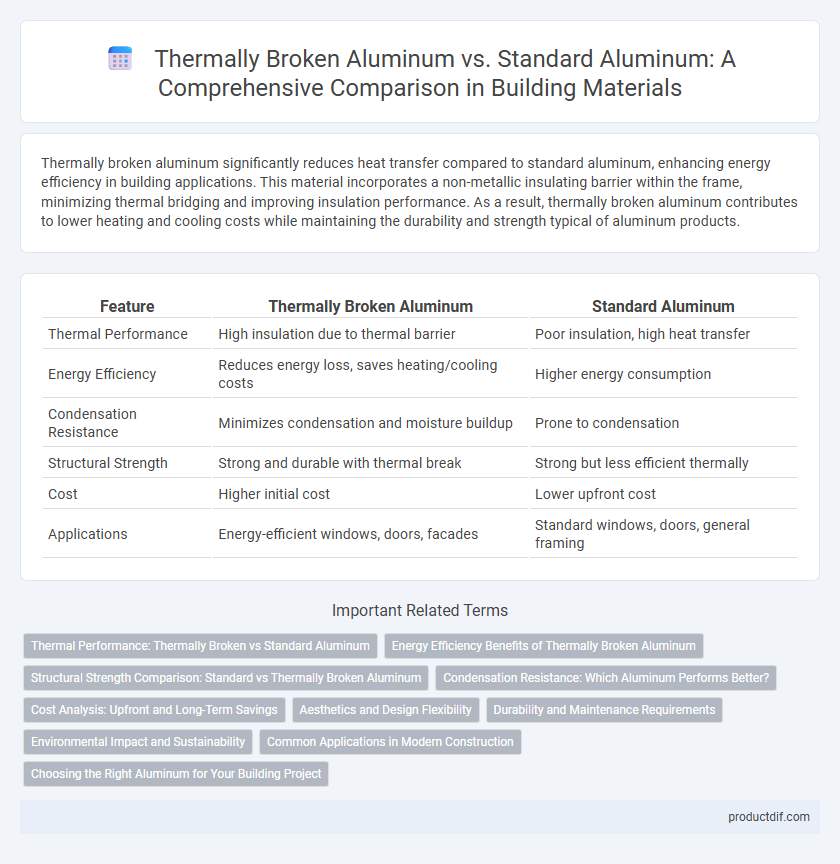

Table of Comparison

| Feature | Thermally Broken Aluminum | Standard Aluminum |

|---|---|---|

| Thermal Performance | High insulation due to thermal barrier | Poor insulation, high heat transfer |

| Energy Efficiency | Reduces energy loss, saves heating/cooling costs | Higher energy consumption |

| Condensation Resistance | Minimizes condensation and moisture buildup | Prone to condensation |

| Structural Strength | Strong and durable with thermal break | Strong but less efficient thermally |

| Cost | Higher initial cost | Lower upfront cost |

| Applications | Energy-efficient windows, doors, facades | Standard windows, doors, general framing |

Thermal Performance: Thermally Broken vs Standard Aluminum

Thermally broken aluminum significantly improves thermal performance by incorporating a non-metallic barrier between the interior and exterior aluminum frames, reducing heat transfer and enhancing insulation. Standard aluminum lacks this barrier, allowing heat and cold to pass freely through the frame, leading to higher energy loss and reduced energy efficiency. This makes thermally broken aluminum ideal for energy-conscious construction projects aiming to meet stringent building codes and improve indoor comfort.

Energy Efficiency Benefits of Thermally Broken Aluminum

Thermally broken aluminum significantly enhances energy efficiency by incorporating a non-metallic thermal barrier that reduces heat transfer between the interior and exterior surfaces. This barrier minimizes thermal bridging, leading to improved insulation values and lower heating and cooling costs compared to standard aluminum frames. Buildings utilizing thermally broken aluminum benefit from reduced energy consumption and increased comfort through better temperature regulation.

Structural Strength Comparison: Standard vs Thermally Broken Aluminum

Standard aluminum offers superior structural strength compared to thermally broken aluminum due to its continuous metal composition, making it ideal for load-bearing applications. Thermally broken aluminum incorporates a non-metallic thermal barrier that reduces heat transfer but slightly compromises rigidity and load capacity. For projects prioritizing maximum structural integrity, standard aluminum frames are preferred, whereas thermally broken aluminum balances strength with enhanced thermal performance.

Condensation Resistance: Which Aluminum Performs Better?

Thermally broken aluminum outperforms standard aluminum in condensation resistance due to its built-in thermal barrier that minimizes heat transfer between interior and exterior surfaces, reducing the risk of condensation. Standard aluminum, being a solid metal without thermal breaks, conducts heat readily, making it more susceptible to condensation buildup in temperature-differing environments. The enhanced thermal insulation properties of thermally broken aluminum significantly improve energy efficiency and prevent moisture-related issues in building envelopes.

Cost Analysis: Upfront and Long-Term Savings

Thermally broken aluminum products have a higher upfront cost compared to standard aluminum due to the inclusion of insulating materials that enhance thermal performance. Long-term savings emerge from reduced energy consumption and lower heating and cooling expenses, making thermally broken aluminum more cost-effective over time. Standard aluminum lacks thermal insulation, often resulting in higher utility bills and potential condensation issues that can increase maintenance costs.

Aesthetics and Design Flexibility

Thermally broken aluminum offers enhanced aesthetics with its sleek, modern look combined with a superior thermal barrier that allows for slimmer profiles and larger glazing areas. This design flexibility enables architects to create more expansive, visually appealing facades without compromising energy efficiency. In contrast, standard aluminum typically features thicker frames due to heat transfer concerns, limiting design possibilities and reducing overall aesthetic appeal.

Durability and Maintenance Requirements

Thermally broken aluminum offers enhanced durability compared to standard aluminum due to its insulated barrier that reduces thermal expansion and contraction, minimizing structural stress over time. This improved thermal performance also lowers the risk of corrosion and condensation-related damage, significantly reducing maintenance requirements. Standard aluminum, lacking this thermal barrier, often experiences more frequent upkeep due to greater susceptibility to temperature fluctuations and related wear.

Environmental Impact and Sustainability

Thermally broken aluminum significantly reduces thermal bridging, leading to lower energy consumption for heating and cooling compared to standard aluminum, enhancing building energy efficiency. Its incorporation of insulating materials between aluminum sections contributes to improved sustainability by reducing greenhouse gas emissions associated with HVAC usage. The use of thermally broken aluminum supports green building certifications and aligns with environmentally responsible construction practices.

Common Applications in Modern Construction

Thermally broken aluminum is widely used in modern construction for energy-efficient window frames, curtain walls, and doors, significantly reducing heat transfer compared to standard aluminum. Standard aluminum remains popular in applications where structural strength and cost-effectiveness are prioritized over thermal performance, such as interior partitions and non-insulated facades. Both materials serve distinct roles in building envelopes, with thermally broken aluminum enhancing energy efficiency and compliance with green building standards.

Choosing the Right Aluminum for Your Building Project

Thermally broken aluminum offers superior insulation by incorporating a non-metallic barrier between the interior and exterior aluminum components, reducing heat transfer and improving energy efficiency in building projects. Standard aluminum lacks this thermal separation, resulting in higher heat conductivity and potential condensation issues, making it less suitable for climate-sensitive applications. Selecting thermally broken aluminum ensures enhanced thermal performance and compliance with stringent building codes, crucial for sustainable and energy-efficient construction.

Thermally broken aluminum vs Standard aluminum Infographic

productdif.com

productdif.com