Galvanized nails offer corrosion resistance through a zinc coating, making them ideal for outdoor use where moisture exposure is a concern, while stainless steel nails provide superior rust resistance and strength, suitable for harsh environments and heavy-duty applications. The choice between galvanized and stainless steel nails depends on factors such as budget, exposure to elements, and the structural requirements of the project. Stainless steel nails generally have a higher cost but deliver long-term durability in corrosive settings compared to galvanized nails.

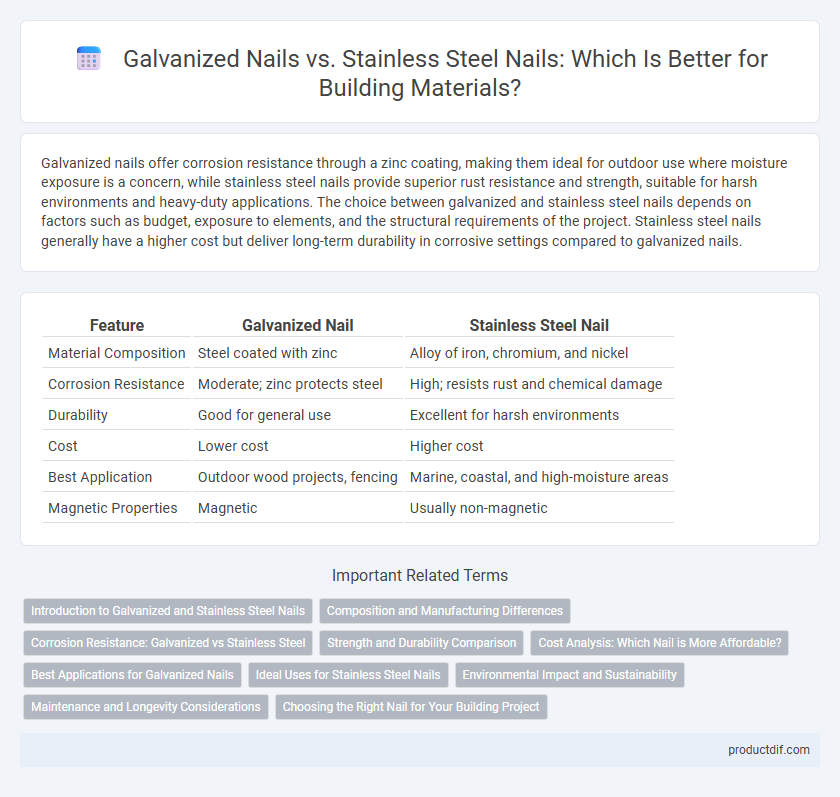

Table of Comparison

| Feature | Galvanized Nail | Stainless Steel Nail |

|---|---|---|

| Material Composition | Steel coated with zinc | Alloy of iron, chromium, and nickel |

| Corrosion Resistance | Moderate; zinc protects steel | High; resists rust and chemical damage |

| Durability | Good for general use | Excellent for harsh environments |

| Cost | Lower cost | Higher cost |

| Best Application | Outdoor wood projects, fencing | Marine, coastal, and high-moisture areas |

| Magnetic Properties | Magnetic | Usually non-magnetic |

Introduction to Galvanized and Stainless Steel Nails

Galvanized nails feature a protective zinc coating that enhances resistance to rust and corrosion, making them ideal for outdoor construction and woodworking projects exposed to moisture. Stainless steel nails consist of an alloy containing chromium and nickel, offering superior durability and corrosion resistance in highly corrosive environments such as marine or acidic conditions. Both nails are essential choices in building materials, with galvanized nails providing cost-effective rust prevention and stainless steel nails delivering maximum longevity and strength.

Composition and Manufacturing Differences

Galvanized nails are primarily made of carbon steel coated with a layer of zinc to prevent corrosion, while stainless steel nails are composed of iron alloyed with chromium, nickel, and other metals, offering inherent rust resistance. The manufacturing process of galvanized nails involves dipping steel nails into molten zinc or applying zinc electroplating, whereas stainless steel nails are produced through alloy melting and solidification without additional coating. These compositional and manufacturing differences directly influence the nails' durability, corrosion resistance, and suitability for various construction environments.

Corrosion Resistance: Galvanized vs Stainless Steel

Galvanized nails are coated with a layer of zinc that provides effective corrosion resistance in typical outdoor and construction environments but may degrade over time when exposed to harsh chemicals or saltwater. Stainless steel nails offer superior long-term corrosion resistance due to their chromium content, which forms a passive oxide layer preventing rust in highly corrosive conditions such as marine environments. Choosing stainless steel nails is essential for projects requiring maximum durability and resistance to corrosion, especially in coastal or industrial settings.

Strength and Durability Comparison

Galvanized nails feature a zinc coating that provides moderate corrosion resistance, making them suitable for outdoor projects with less exposure to moisture. Stainless steel nails offer superior strength and exceptional durability due to their resistance to rust, making them ideal for high-moisture or coastal environments. The choice between galvanized and stainless steel nails depends on the specific environmental conditions and the required longevity of the construction.

Cost Analysis: Which Nail is More Affordable?

Galvanized nails typically offer a more affordable option compared to stainless steel nails due to lower material and manufacturing costs. Stainless steel nails provide superior corrosion resistance but come at a higher price point, often two to three times that of galvanized nails. For budget-conscious construction projects requiring moderate durability, galvanized nails present the best cost-efficiency balance.

Best Applications for Galvanized Nails

Galvanized nails offer superior corrosion resistance, making them ideal for outdoor and moist environments such as fencing, decking, and roofing projects. Their zinc coating protects against rust, extending the lifespan of wooden structures exposed to weather. Galvanized nails are preferred for applications where moderate durability and cost-efficiency are essential.

Ideal Uses for Stainless Steel Nails

Stainless steel nails are ideal for exterior applications and environments exposed to moisture or corrosive elements, such as coastal areas or treated lumber. Their superior corrosion resistance prevents rust and staining, making them essential for decking, siding, and roofing projects requiring long-term durability. Unlike galvanized nails, stainless steel nails maintain structural integrity in harsh conditions, ensuring lasting performance in high-humidity or saltwater-prone locations.

Environmental Impact and Sustainability

Galvanized nails typically have a zinc coating that can leach into soil and water, posing moderate environmental concerns during disposal or corrosion. Stainless steel nails offer greater longevity and recyclability, reducing the need for frequent replacement and minimizing waste generation. Choosing stainless steel nails supports sustainability goals by ensuring durability and lower environmental toxicity compared to galvanized alternatives.

Maintenance and Longevity Considerations

Galvanized nails offer moderate corrosion resistance due to their zinc coating, making them suitable for indoor or dry environments where maintenance is minimal. Stainless steel nails provide superior durability and corrosion resistance in harsh or wet conditions, reducing the need for frequent replacements and maintenance. Choosing stainless steel nails enhances longevity in outdoor construction, while galvanized nails balance cost and performance for less demanding applications.

Choosing the Right Nail for Your Building Project

Galvanized nails resist corrosion through a zinc coating, making them ideal for outdoor projects exposed to moisture, such as decks and fences. Stainless steel nails offer superior rust resistance and strength, suitable for marine environments or structures requiring long-term durability. Selecting the right nail depends on project exposure, budget, and expected lifespan to ensure structural integrity and prevent material degradation.

Galvanized Nail vs Stainless Steel Nail Infographic

productdif.com

productdif.com