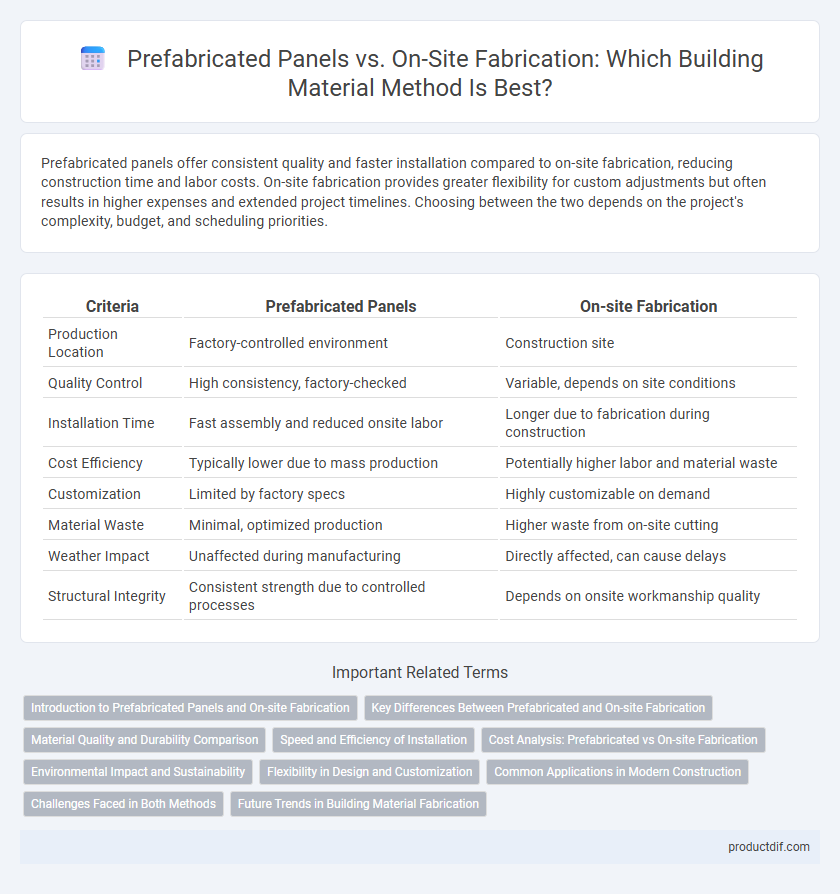

Prefabricated panels offer consistent quality and faster installation compared to on-site fabrication, reducing construction time and labor costs. On-site fabrication provides greater flexibility for custom adjustments but often results in higher expenses and extended project timelines. Choosing between the two depends on the project's complexity, budget, and scheduling priorities.

Table of Comparison

| Criteria | Prefabricated Panels | On-site Fabrication |

|---|---|---|

| Production Location | Factory-controlled environment | Construction site |

| Quality Control | High consistency, factory-checked | Variable, depends on site conditions |

| Installation Time | Fast assembly and reduced onsite labor | Longer due to fabrication during construction |

| Cost Efficiency | Typically lower due to mass production | Potentially higher labor and material waste |

| Customization | Limited by factory specs | Highly customizable on demand |

| Material Waste | Minimal, optimized production | Higher waste from on-site cutting |

| Weather Impact | Unaffected during manufacturing | Directly affected, can cause delays |

| Structural Integrity | Consistent strength due to controlled processes | Depends on onsite workmanship quality |

Introduction to Prefabricated Panels and On-site Fabrication

Prefabricated panels are factory-made building components designed for quick assembly at the construction site, enhancing precision and reducing labor costs. On-site fabrication involves creating materials directly at the construction location, allowing customization but often increasing time and potential for errors. Comparing both methods highlights the trade-offs between efficiency, quality control, and flexibility in construction projects.

Key Differences Between Prefabricated and On-site Fabrication

Prefabricated panels are manufactured in controlled factory settings, ensuring consistent quality, reduced waste, and faster installation times compared to on-site fabrication. On-site fabrication allows for greater customization and adaptability to specific project requirements but often results in longer construction timelines and increased labor costs. Key differences include the level of precision, project speed, cost efficiency, and environmental impact associated with each method.

Material Quality and Durability Comparison

Prefabricated panels are manufactured in controlled factory settings, ensuring consistent material quality and enhanced durability through standardized processes and rigorous quality control. On-site fabrication often faces variability due to environmental conditions and workmanship, potentially impacting material integrity and longevity. Studies indicate prefabricated panels frequently exhibit superior resistance to moisture, fire, and structural stresses compared to on-site fabricated materials, leading to longer service life and reduced maintenance costs.

Speed and Efficiency of Installation

Prefabricated panels significantly reduce construction time by being manufactured off-site under controlled conditions, allowing for simultaneous site preparation and panel production. On-site fabrication often experiences delays due to weather, labor availability, and complexity of assembly, which can extend project timelines. The efficiency of installation with prefabricated panels minimizes site disruption and labor costs, making it a preferred choice for rapid project delivery.

Cost Analysis: Prefabricated vs On-site Fabrication

Prefabricated panels often reduce labor costs by up to 30% compared to on-site fabrication due to streamlined manufacturing and shorter installation times. On-site fabrication incurs higher expenses from labor-intensive processes and potential material waste driven by weather delays and site constraints. Analyzing total project costs reveals prefabrication offers consistent savings in labor and material efficiency, despite higher initial panel costs.

Environmental Impact and Sustainability

Prefabricated panels significantly reduce construction waste and energy consumption by optimizing factory production processes, leading to lower carbon emissions compared to on-site fabrication. The controlled environment of prefabrication enhances material efficiency and allows for better recycling of offcuts, promoting a circular economy within the building material sector. On-site fabrication often results in higher resource wastage and increased transportation emissions, making prefabricated panels a more sustainable choice for eco-friendly construction projects.

Flexibility in Design and Customization

Prefabricated panels offer standardized design options with limited customization, streamlining production but restricting architectural flexibility. On-site fabrication enables extensive design variations and tailored modifications to meet specific project requirements, enhancing adaptability in complex or unique structures. The choice between the two depends on the balance between project uniqueness and the need for rapid assembly.

Common Applications in Modern Construction

Prefabricated panels are widely used in residential housing, commercial buildings, and modular construction projects due to their quick installation and consistent quality. On-site fabrication remains preferred for custom architectural features, unique design elements, and projects requiring structural adaptability. Both methods contribute significantly to modern construction by optimizing project timelines and material efficiency.

Challenges Faced in Both Methods

Prefabricated panels face challenges such as transportation risks, limited customization on-site, and dependency on factory schedules, affecting project timelines and cost efficiency. On-site fabrication encounters issues like weather delays, site space constraints, and labor skill variability, which can lead to inconsistent quality and extended construction periods. Both methods demand precise coordination and quality control to mitigate errors and ensure structural integrity in building projects.

Future Trends in Building Material Fabrication

Prefabricated panels offer faster construction times and enhanced quality control by producing components in controlled factory settings, reducing waste and labor costs. On-site fabrication provides flexibility for custom designs and adjustments but often faces challenges in efficiency and consistency due to weather and site conditions. Future trends emphasize integrating digital fabrication technologies like 3D printing and robotics in both methods to improve precision, sustainability, and scalability in building material production.

Prefabricated panels vs On-site fabrication Infographic

productdif.com

productdif.com