Oriented Strand Board (OSB) offers cost-effective durability with a consistent density, making it suitable for wall sheathing and subflooring in construction. Plywood provides superior moisture resistance and strength due to its cross-laminated veneer layers, ideal for applications exposed to humidity or structural loads. Both materials are essential in building projects, with OSB favored for budget efficiency and plywood for enhanced performance.

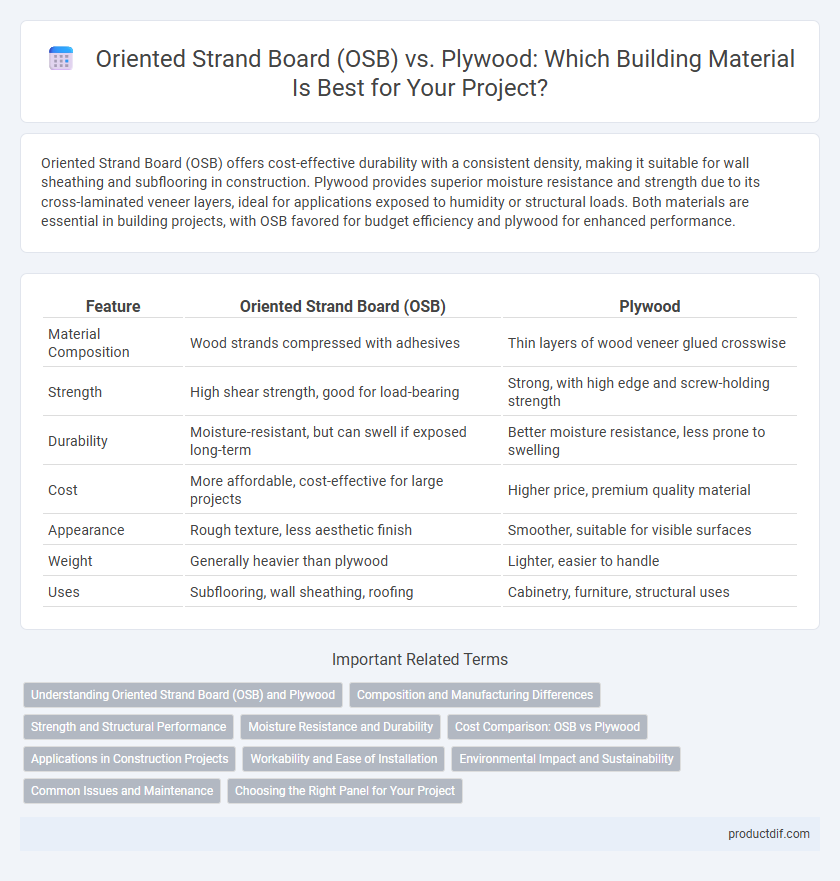

Table of Comparison

| Feature | Oriented Strand Board (OSB) | Plywood |

|---|---|---|

| Material Composition | Wood strands compressed with adhesives | Thin layers of wood veneer glued crosswise |

| Strength | High shear strength, good for load-bearing | Strong, with high edge and screw-holding strength |

| Durability | Moisture-resistant, but can swell if exposed long-term | Better moisture resistance, less prone to swelling |

| Cost | More affordable, cost-effective for large projects | Higher price, premium quality material |

| Appearance | Rough texture, less aesthetic finish | Smoother, suitable for visible surfaces |

| Weight | Generally heavier than plywood | Lighter, easier to handle |

| Uses | Subflooring, wall sheathing, roofing | Cabinetry, furniture, structural uses |

Understanding Oriented Strand Board (OSB) and Plywood

Oriented Strand Board (OSB) is an engineered wood product made from compressed layers of wood strands bonded with adhesives, offering high shear strength and moisture resistance, making it ideal for wall sheathing and subflooring. Plywood consists of thin layers of wood veneer glued crosswise, providing superior dimensional stability and resistance to warping, frequently used in cabinetry and furniture. Both materials vary in cost, durability, and application suitability, with OSB generally being more cost-effective and plywood offering better moisture durability.

Composition and Manufacturing Differences

Oriented Strand Board (OSB) is made from compressed layers of wood strands arranged in specific orientations, bonded with synthetic resin adhesives, providing uniform strength and moisture resistance. Plywood consists of thin wood veneers glued together with alternating grain directions to enhance durability and reduce warping. OSB manufacturing emphasizes strand alignment and resin application, while plywood relies on veneer layering and pressing techniques for its structural integrity.

Strength and Structural Performance

Oriented Strand Board (OSB) offers comparable strength to plywood with its engineered layering of wood strands, enhancing shear and bending resistance ideal for load-bearing applications. Plywood typically demonstrates superior tensile strength and moisture resistance due to its cross-laminated veneer structure, making it preferred for environments subject to high humidity. Structural performance for both materials meets building codes, but OSB provides cost-effective shear strength while plywood excels in durability and long-term stability.

Moisture Resistance and Durability

Oriented Strand Board (OSB) offers enhanced moisture resistance compared to traditional plywood due to its resin-coated wood strands that prevent water absorption and swelling. Plywood consists of thin veneers glued together, making it susceptible to delamination and warping when exposed to prolonged moisture. The durability of OSB in humid conditions often surpasses that of plywood, making it a preferred choice for subflooring and wall sheathing in areas prone to moisture exposure.

Cost Comparison: OSB vs Plywood

Oriented Strand Board (OSB) typically costs 10-20% less than plywood, making it a budget-friendly choice for construction projects. OSB's manufacturing process uses fast-growing trees and smaller wood strands, reducing material expenses compared to plywood's layers of veneer. Despite cost advantages, factors like durability and moisture resistance should be considered alongside price when selecting between OSB and plywood.

Applications in Construction Projects

Oriented Strand Board (OSB) is widely used for wall sheathing, roof decking, and subflooring due to its strength and cost-effectiveness, making it ideal for residential and commercial construction projects. Plywood offers superior moisture resistance and dimensional stability, which makes it preferable for applications such as exterior walls, roofing underlayment, and cabinetry where exposure to humidity is a concern. Both materials provide structural integrity, but OSB is favored in budget-sensitive projects, whereas plywood is chosen for its durability and finish quality in high-performance construction environments.

Workability and Ease of Installation

Oriented Strand Board (OSB) offers uniform thickness and large panel size, enhancing workability for cutting and fastening in construction projects. Plywood provides superior flexibility and smoother surfaces, making it easier to handle and install in curved or irregular spaces. Both materials are compatible with standard woodworking tools, but OSB typically requires more attention to edges due to its rough texture.

Environmental Impact and Sustainability

Oriented Strand Board (OSB) is produced using fast-growing, small-diameter trees, enabling more efficient forest resource utilization compared to plywood, which often requires larger, old-growth timber. OSB manufacturing processes typically involve less energy consumption and utilize adhesives with lower formaldehyde emissions, contributing to reduced environmental impact. Both materials are recyclable and can be sourced from sustainably managed forests, but OSB's optimized raw material use and lower waste generation make it a more sustainable choice in construction.

Common Issues and Maintenance

Oriented Strand Board (OSB) often faces issues with moisture absorption, leading to swelling and degradation if not properly sealed, while plywood exhibits better water resistance and dimensional stability. Maintenance of OSB requires thorough sealing and frequent inspections to prevent water damage, whereas plywood demands less intensive care but benefits from occasional refinishing to maintain durability. Both materials need proper ventilation and protective coatings to extend lifespan in exterior applications.

Choosing the Right Panel for Your Project

Oriented Strand Board (OSB) offers cost-effective structural strength and moisture resistance, making it ideal for subflooring and wall sheathing in residential construction. Plywood provides superior durability, better screw-holding capacity, and enhanced aesthetic appeal, suitable for cabinetry, roofing, and exposed applications. Selecting the right panel depends on project requirements like load-bearing capacity, budget constraints, and environmental exposure.

Oriented Strand Board (OSB) vs Plywood Infographic

productdif.com

productdif.com