Copper pipes offer superior durability and excellent resistance to high temperatures, making them ideal for long-lasting plumbing installations. PEX pipes provide greater flexibility and easier installation, which reduces labor costs and time significantly. Choosing between copper and PEX depends on factors like budget, installation complexity, and the specific needs of the building project.

Table of Comparison

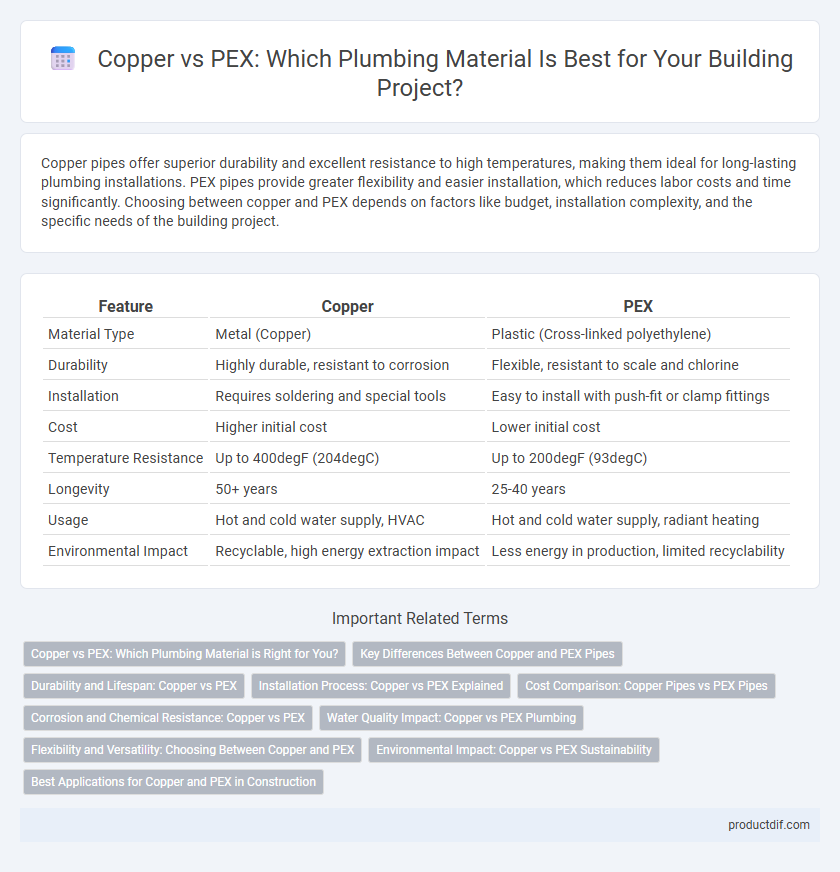

| Feature | Copper | PEX |

|---|---|---|

| Material Type | Metal (Copper) | Plastic (Cross-linked polyethylene) |

| Durability | Highly durable, resistant to corrosion | Flexible, resistant to scale and chlorine |

| Installation | Requires soldering and special tools | Easy to install with push-fit or clamp fittings |

| Cost | Higher initial cost | Lower initial cost |

| Temperature Resistance | Up to 400degF (204degC) | Up to 200degF (93degC) |

| Longevity | 50+ years | 25-40 years |

| Usage | Hot and cold water supply, HVAC | Hot and cold water supply, radiant heating |

| Environmental Impact | Recyclable, high energy extraction impact | Less energy in production, limited recyclability |

Copper vs PEX: Which Plumbing Material is Right for You?

Copper pipes offer durability, resistance to corrosion, and can handle high temperatures, making them ideal for long-term plumbing systems. PEX tubing provides flexibility, faster installation, and resistance to scale and chlorine, which reduces the risk of leaks and freezing damage. Evaluating factors such as budget, water quality, and climate will help determine whether copper or PEX is the best choice for your plumbing needs.

Key Differences Between Copper and PEX Pipes

Copper pipes offer superior durability and corrosion resistance, making them ideal for long-term use in plumbing systems. PEX pipes provide greater flexibility and ease of installation, reducing labor costs and allowing for quicker adaptation to complex layouts. Temperature tolerance varies, with copper able to withstand higher heat levels while PEX resists scale buildup and chemical damage more effectively.

Durability and Lifespan: Copper vs PEX

Copper pipes offer exceptional durability with a lifespan exceeding 50 years, resistant to corrosion and high temperatures, making them ideal for long-term plumbing solutions. PEX pipes have a lifespan of 40 to 50 years, noted for flexibility and resistance to scale and chlorine, but they may degrade under prolonged UV exposure and extreme heat. When comparing durability and lifespan, copper remains the preferred choice for applications demanding robustness and long-term reliability.

Installation Process: Copper vs PEX Explained

Copper pipes require soldering and precise fittings, demanding skilled labor and specialized tools, which can extend installation time and complexity. PEX tubing offers flexible, kink-resistant properties with a simpler, tool-free crimp or clamp connection system, significantly reducing installation time and labor costs. The ease of maneuvering PEX around corners without additional fittings enhances efficiency compared to rigid copper piping.

Cost Comparison: Copper Pipes vs PEX Pipes

Copper pipes generally have higher upfront costs, ranging from $2 to $4 per linear foot, compared to PEX pipes, which cost between $0.50 and $2 per linear foot. Installation expenses also favor PEX due to its flexibility and ease of handling, reducing labor time and associated costs. Overall, PEX pipes offer a more cost-effective solution for plumbing projects, while copper provides added durability and longevity.

Corrosion and Chemical Resistance: Copper vs PEX

Copper exhibits strong resistance to microbial corrosion but can corrode over time when exposed to acidic or alkaline water conditions, leading to pinhole leaks. PEX (cross-linked polyethylene) demonstrates superior chemical resistance, unaffected by most acids, alkalis, and chemicals found in plumbing systems, reducing the risk of degradation and leaks. The choice between copper and PEX should consider the specific water chemistry and environmental factors to optimize durability and longevity.

Water Quality Impact: Copper vs PEX Plumbing

Copper plumbing offers natural antimicrobial properties that inhibit bacterial growth, ensuring superior water quality compared to PEX, which can harbor biofilm if not properly maintained. PEX pipes resist corrosion and scale buildup, reducing the risk of contaminants like lead or copper leaching into the water supply, but may experience chemical leaching from additives under certain conditions. Both materials impact water taste and safety differently, with copper favoring mineral safeguarding and PEX emphasizing chemical stability and flexibility.

Flexibility and Versatility: Choosing Between Copper and PEX

PEX piping offers superior flexibility compared to copper, allowing for easier installation around corners and reduced need for fittings, which minimizes potential leak points. Copper provides excellent durability and heat resistance but is rigid, requiring more connectors and labor during installation. The versatility of PEX in adapting to various plumbing layouts often makes it the preferred choice for complex or tight spaces.

Environmental Impact: Copper vs PEX Sustainability

Copper offers high recyclability and durability, contributing to lower environmental impact through reduced waste and longer service life. PEX, made from cross-linked polyethylene, presents lower embodied energy in production but raises concerns due to limited recyclability and potential chemical leaching. Evaluating sustainability involves balancing copper's resource-intensive mining with PEX's plastic pollution challenges and lifespan differences.

Best Applications for Copper and PEX in Construction

Copper excels in high-temperature and high-pressure plumbing applications due to its durability, corrosion resistance, and antimicrobial properties, making it ideal for hot water supply and industrial systems. PEX is highly flexible, resistant to scale and chlorine, and easier to install, which suits it perfectly for residential water distribution, radiant floor heating, and retrofit projects. Choosing between copper and PEX often depends on specific building requirements, budget constraints, and long-term maintenance considerations in construction.

Copper vs PEX Infographic

productdif.com

productdif.com